Duty-free Import and Slowdown in the Economy affect Orient Papers Profit; INR 19 crore earned in FY 19-20

Duty-free Import and Slowdown in the Economy affect Orient Papers Profit; INR 19 crore earned in FY 19-20

Bhubaneswar | 3rd September 2020 | The Pulp and Paper Times:

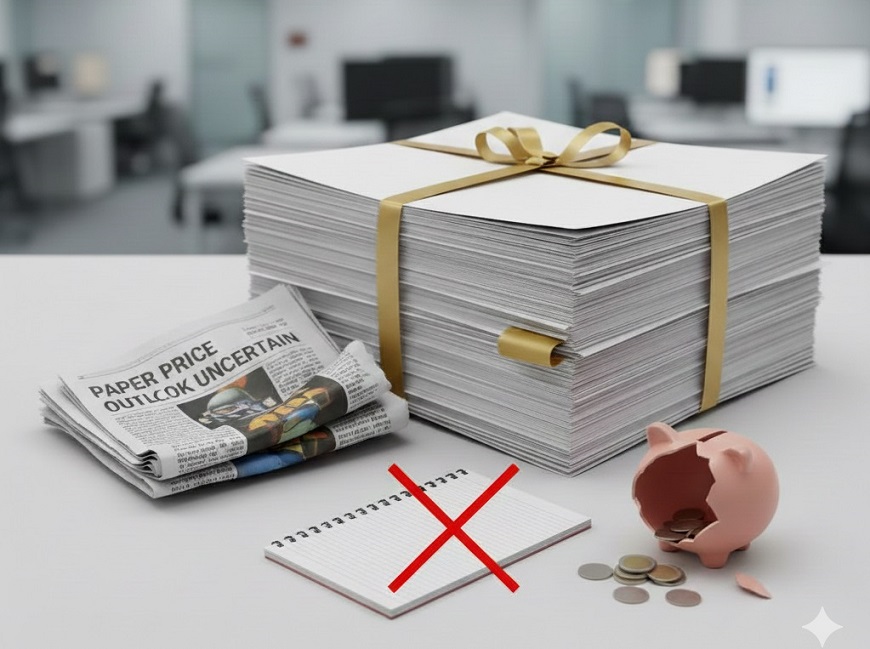

The year FY19-20 was one of the most challenging periods encountered by not only the Indian economy and the paper sector but also Orient Paper. The growth of the Indian economy slowed from 6.1% in FY18-19 to 4.2% in FY19-20 and to a multi-quarter low of 3.1% during the fourth quarter of the year under review. The global economy also slowed, aggravating challenges from the export markets.

"At Orient Paper, our performance was also affected by the slowdown in Indian economy coupled with a pressure on price realisations due to increased duty-free imports based on a steep drop in international pulp and paper prices and the disruption caused by the COVID-19 pandemic across the world," says Mr. M.L. Pachisia, Managing Director at Orient Paper & Industries Limited in the annual report for FY 19-20.

"Notwithstanding these challenges, we have taken several proactive steps to focus deeper on leveraging our resilience by cutting costs, maximising operating efficiencies and generating more from less. An increased focus on continuous improvement (kaizen) translated into a number of cross-functional enhancements. The cumulative effect of these initiatives mitigated the impact of the above factors substantially,"

"We still invested more than ever in sustainability and responsibilities by enhancing our long-term water security, reducing consumption of natural resources, ensuring environmental compliances and expanding the scope of our social service initiatives," Mr. CK Birla, Chairman of Orient Paper & Industries Limited says in the report.

Orient Paper's average sales realization for paper declined by nearly 3% compared to the previous year, while the caustic soda realisations declined by as much as 18%.

Further, an unexpected increase in the cost of pulpwood, following NGO activism against the movement of wood in Madhya Pradesh during the second and third quarters of the year, compelling the company to increase sourcing from distant locations, which, in turn, increased procurement costs. However, this disruption was overcome in the fourth quarter when the restriction caused by the introduction of transit permits eased.

As a result of the challenges faced during the year, Orient Paper’s turnover for the year was lower at INR 606.56 crores compared to INR 710.04 crores last year, achieved a PBIDT of INR 59.33 crores and cash profit of INR 54.10 crores. Net profit after tax was INR 19.93 crores this year.

New Product Development:

• Developed Napkin Grade Tissue Paper in 14 gsm for the domestic market.

• Developed Toilet grade Tissue Paper in 14 gsm both for overseas as well as domestic market

Pulping Capacity & efficiency:

Orient Paper is also in the process of increasing our pulping capacity which will reduce its dependency on imported pulp and also provide a scope for increasing our tissue paper capacity. Simultaneously the company is taking several steps to cut down both our direct and overhead costs which will provide us with lasting benefits even after normalcy returns. Therefore, while there are likely to be some challenges in the short term, Orient Paper expects to come out stronger once normalcy returns.

Resource augmentation:

Pulpwood availability in India is another continuing challenge. Orient Paper have been working towards ensuring virtual self-sufficiency in procurement of pulpwood from areas close to our plant to achieve twin objectives of helping the environment and lowering landed cost of pulpwood. Toward this objective, we have set up a world class clonal development center to produce high yielding clones for distribution to the farmers at a low cost and have so far already covered around 63289 hectares of land with plantations. This is expected to result in increasing quantum of wood year on year.

Technology absorption and Innovation:

Efforts in brief made towards absorption, adoption and innovation:

Raw Material Development

• Maintain the FIFO in yard to get the standard raw material furnish mix (Fresh Vs stacked material) and supplied to chipper house to get the uniform mixing of raw material to get best properties in the pulp.

• Spray showers on chipper feed conveyor modified for better chips washing and uniform chips moisture to get the better cleanliness of the pulp and for getting the uniform pulping.

Pulp Mill:

• To improve the pulp whiteness by optimizing of H2O2 dose in Pulp Mill to reduce the yellowness in final bleached pulp visà -vis to reduce the usage of costlier Optical whitening agent at paper machine and to get the permanency of the paper in terms of shade and brightness.

• Washing efficiency further increased by 0.5% by reducing the soda losses to get the minimum chemical carry-over for achieving the consistent bleached pulp quality.

Chemical Recovery, Chlorine Dioxide plant & Lime Kiln

• Improve Active Alkali content in White liquor by 2.0 gpl (from 78.0 to 80.0 gpl) to improve the strength index of the unbleached pulp.

• Sulphidity of the white liquor increased by 1.0% to get the higher strength index of pulp.

• Installed New outlet & bypass damper at ESP of RB to improve running life of RB between two passage cleaning from 30 days to 45 days.

• Installed & Commissioned new Lime mud filter at the causticizing section to give increase lime mud dryness by 5 % (from 58 % to 63 %)

Paper Machine

• New pressure screen installed and commissioned at main machine to improve the paper quality in terms of cleanliness of the paper.

• Mounted new 600 rpm motor at finishing refiner at main machine and stopped one TDR 30†to give power savings of 250 kwh.

• VFD installed in refiner feed pump to get the uniform refining of the pulp which improved the paper surface and strength properties of the paper.

• Drum roll coating done at main machine rewinder to get the better reel quality in terms of uniform and tight binding of the reels.

• Epoxy flooring done at the operating floor at main machine rewinder to eliminate any dust accumulation on the paper surface.

Mr. Pachisia further states, we reckon that the current challenges are likely to last for some time. Therefore, our focus will be on a continuous rationalisation of costs and managing our cash flows most prudently. In this respect, the Company is well-placed to face the impact of the pandemic on account of a relatively strong Balance Sheet.

Orient paper had only INR 3.57 cr in long term debt at the year-end, while operating in a capital-intensive business. Therefore, we are relatively better-placed to duck the storm and be ready for demand revival when the slowdown and pandemic impacts wane.

Web Title: Duty free Import and Slowdown in the Economy affect Orient Paper s Profit INR 19 crore earned in FY 19 20

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)