Scan Machineries commissions another Green Field Paper Mill Project

Scan Machineries commissions another Green Field Paper Mill Project

25th June 2021 | The Pulp and Paper Times:

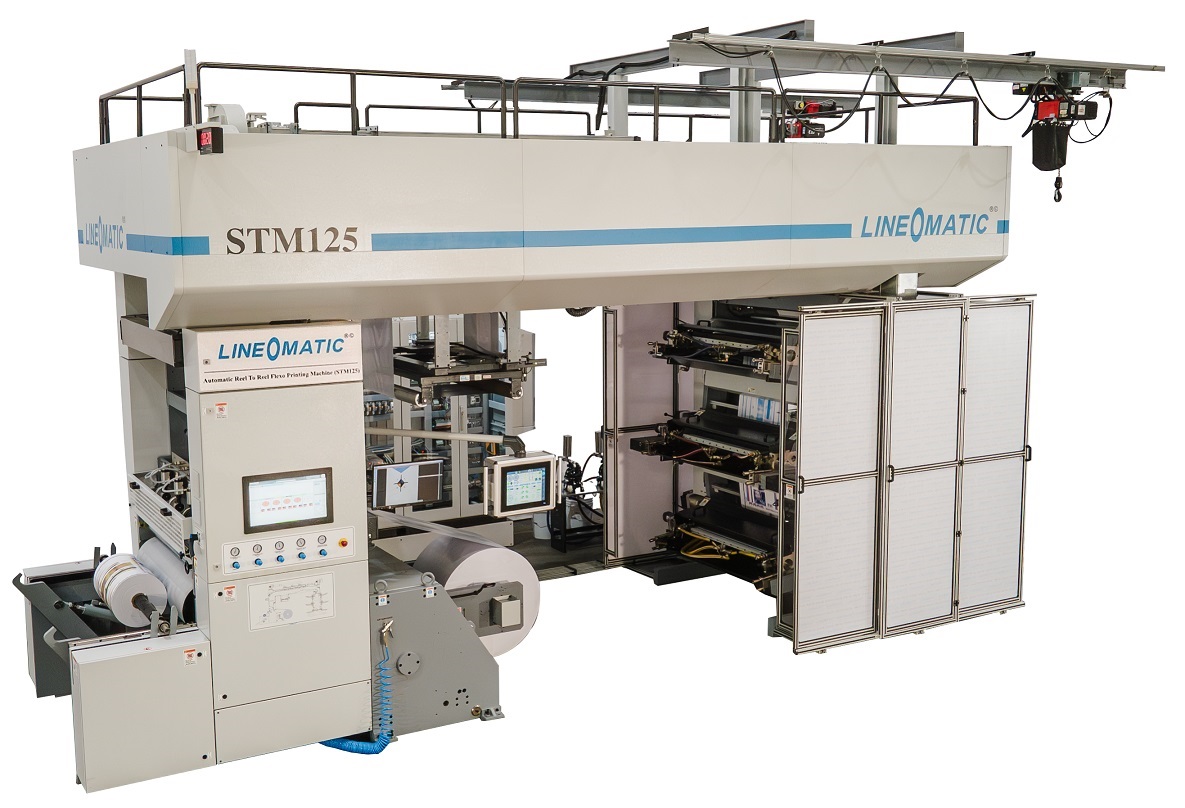

Scan Machineries has commissioned a new Double Wire Fourdrinier Paper Machine in Zambia, Africa which produces Kraft Paper of Test Liner, Fluting Medium and White Top varieties. The new production line has a deckle width of 2600 mm which produces paper in the range of 70 - 250grammage (GSM).

Scan Machineries had engineered and commissioned the Paper Mill Project on Turnkey Basis for Book Hut Limited, Zambia. “Scan has done complete engineering for the entire Paper Mill including Stock Preparation Line, Paper Machine, civil layout including detailed structural engineering. Scan had designed and supplied machinery starting from the conveyor to the machine chests of the stock preparation, the approach flow as well as from the headbox to winder of the Paper Machine,†said Mr. Gitesh Patel, Managing Director of Book Hut Limited.

Mr. J Vinod Nargunam, ED of Scan Machineries says on the commissioning of the machine, “We would like to thank our customer Mr. Gitesh Patel (Managing Director) and Mr. Kunal Patel (Director) of Book Hut Limited for giving us this amazing opportunity to provide and supply the finest paper machinery and offer our elite engineering consultancy services to them. It is a proud moment to say that Scan Machineries had reeled Paper within 10 hours on the first day of startup. Within one month of startup, Book Hut Limited has become the market leaders in Zambia catering to many convertors and corrugating units. Their presence in the market has been increasing steadily at a rapid pace and is pushing to expand their presence overseas in the coming daysâ€

The Paper Machine includes a double wire in the wet end section with two highly efficient nip press loads, a pre dryer section, a size press,a post dryer section, a calandar, a pope and a winderwith an automatic quality control system (QCS) for best sheet quality and formation.The sludge from the Paper Machine is used in manufacturing Egg Trays in Book Hut Limited’s Egg Tray plant situated near the Paper Mill ensuring substantial savings of fibers and costs for the customer. This was specially designed to ensure the waste materials to be used in another process cycle as raw materials such as in an in-house Egg Tray plant and the complete production line is designed for zero discharge.

The pipeline design, water balancing and layout was designed by Scan Machineries. Detailed electrical engineering was done for the entire Paper Mill which is designed for less power consumption to ensure sustainability and green energy conservation. Complete erection and commissioning was completed and training of man power to handle the Paper Mill at a high efficiency was ensured by Scan Machineries Team.

Web Title: Scan Machineries commissions another Green Field Paper Mill Project

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)