New wave of paper innovations: OGR, Pharma Print, and High BF Paper for Bags — Mr. Kishan says success lies in understanding customers, not just selling paper

The Pulp and Paper Times

Hyderabad, India – In a recent interview on PapExpo Talks, Mr. Thakur Kishan Singh, a prominent figure and Platinum Sponsor of PAPEXPO 2025, shared insightful perspectives on the paper industry, highlighting the paramount importance of service, innovation, and sustainability. As the representative of Tirumala Balaji Paper Private Limited, a key distributor for Emami Paper Mills Ltd. and West Coast Paper Mills across Andhra Pradesh and Telangana, Mr. Singh's company plays a vital role in the region's paper supply chain.

Established in 1968, Thirumala Bajaji Paper has grown under the leadership of the Singh family into a trusted name in the paper distribution business. The company is a proud distributor for two of India’s top paper manufacturers — Emami Paper Mills and West Coast Paper Mills — catering exclusively to the Andhra Pradesh and Telangana markets.

“Taking an order is easy, but delivering it on time is where the real challenge lies,” Singh emphasized, underlining how customer service is the secret sauce behind their sustained success. With multiple branches, including Hyderabad, Vijayawada, and Visakhapatnam, the company ensures seamless supply chain management across the states.

Understanding Customers Is Key

For Singh, success is rooted in deeply understanding customers’ needs. He highlighted that many clients may not be aware of subtle choices that can improve their margins. “For instance, if a client is using 58 GSM paper, we might recommend 56 GSM with the same quality for printing. This saves costs while delivering the same output,” Singh explained.

This advisory approach doesn’t just secure business but builds long-term trust and relationships—a cornerstone in the highly interconnected paper community. He elaborated that while securing orders is straightforward, the real challenge, and the path to limitless success, is consistently serving clients on time.

His company efficiently manages its extensive distribution network throughout Andhra Pradesh and Telangana, with a significant branch in Vijayawada overseen by his brother, Nikhil Singh, and active operations in Visakhapatnam and Hyderabad

The discussion also shed light on the dynamic evolution of the paper industry, particularly its commitment to innovation and environmentally friendly practices. Mr. Singh detailed several groundbreaking new products, including:

Oil and Grease Resistant (OGR) Paper: A significant advancement in food packaging designed to replace traditional newspaper use, ideal for items like burgers.

Paper for Straws: His company is a key supplier of paper used in the manufacturing of paper straws, aligning with the global shift towards eco-conscious alternatives.

Pharma Print: An innovative offering from Emami Paper Mills specifically developed to cater to the stringent requirements of the pharmaceutical sector.

High Strength Paper for Paper Bags: West Coast Paper Mills has introduced this durable paper, enabling the production of robust and reliable paper bags.

Challenging common misconceptions, Mr. Singh passionately advocated for paper as a fundamentally sustainable and eco-friendly material. He underscored paper's recyclability and clarified that the industry predominantly utilizes fibers from renewable sources such as sugarcane, wheat straw, rice straw, and sustainably harvested eucalyptus trees, rather than contributing to deforestation. He strongly asserted that myths suggesting paper avoidance benefits the environment are often propagated to serve the interests of competing industries.

Mr. Singh concluded with an encouraging message for aspiring young entrepreneurs, urging them to consider a career in the paper industry. He described it as a "loyal business" and a "very friendly industry" with promising future prospects. He advised new entrants to prioritize building strong client relationships, maintaining consistent communication, and meticulously managing finances, acknowledging the industry's credit-based operational model. He passionately encouraged promoting, loving, and utilizing paper, emphasizing that a focused approach on packaging and other innovative paper products could lead to an impressive 8% annual growth.

India's total paper consumption sees a 20% share from imports; MIP may lead to higher prices for consumers: Key insights from PMA webinar

- Total imports expected to reach 2.5-2.7 million MT by 2026

- 44% year-on-year increase in paper imports from China during the first half of FY24-25

- India’s Paper Imports projected to grow by 15–20% in FY26

The Pulp and Paper TimesDelhi, India – On May 18, 2025, the Paper Merchants Association (PMA) Delhi successfully hosted an insightful webinar titled "Understanding the Current State and Future of Paper Imports in India." The event brought together industry professionals, stakeholders, and enthusiasts who engaged in in-depth discussions on the rising trends, challenges, and future prospects of paper imports in India. PMA exclusively shared the insight of webinar with The Pulp and Paper Times

The webinar highlighted that paper imports in India reached 1.929 million metric tonnes in FY24, marking a 34% increase from FY23. This surge signifies a growing reliance on imported paper, now accounting for nearly 20% of the country’s total paper consumption. The value of these imports also saw a notable rise—from Rs 6,140 crore in FY21 to Rs 13,248 crore in FY24—reflecting a 29% increase in monetary terms.

Industry experts pointed to ASEAN countries as the primary suppliers, with Free Trade Agreements facilitating their growing presence in the Indian market. A significant portion of the discussion focused on the 44% year-on-year increase in paper imports from China during the first half of FY24-25, and how competitive manufacturing costs in countries like Indonesia and China are reshaping the landscape of Indian imports.

Looking ahead, speakers projected a continued upward trajectory in import volumes, estimating a growth rate of 15-20% through FY25-26. By 2026, total imports could range between 2.5 to 2.7 million metric tonnes, driven by escalating demand and evolving market conditions. The importance of sustainability and digital transformation emerged as critical themes influencing the industry's direction.

Participants also explored the challenges facing the paper import sector, such as aggressive pricing from low-cost foreign producers, the need to match global quality standards, and uncertainties in trade policies that complicate long-term planning. However, the discussion also spotlighted emerging opportunities in sustainable packaging and product innovation, encouraging stakeholders to emphasize value addition and differentiation to stay competitive.

Puneet Jain, a leading expert in the field, noted, “The insights shared during the webinar are crucial for industry stakeholders to navigate the evolving landscape of paper imports. As sustainability becomes a priority, understanding these trends will empower businesses to make informed strategic decisions.”

The Paper Merchants Association Delhi extended its sincere appreciation to all participants and speakers for their engagement and expertise. The knowledge and perspectives shared during the session are expected to serve as a valuable resource for the paper industry as it prepares for the future.

Discussion on Minimum import price (MIP)

The primary aim of the MIP is to prevent the influx of paper products at excessively low prices, which can undermine local manufacturers and adversely affect their profitability. By establishing a minimum price, the government seeks to create a level playing field for domestic producers.

Current Market Dynamics:

The paper industry in India has faced challenges due to a surge in imports, particularly from countries with lower production costs. The MIP is intended to mitigate the adverse effects of this competition and support the long-term sustainability of the sector.

Government's Evaluation Process:

The government is conducting a thorough analysis of the potential benefits and losses related to the MIP. This includes:

Economic Impact: Evaluating how the MIP could affect overall import volumes and pricing structures in the Indian market.

Industry Feedback: Gathering input from industry stakeholders, including manufacturers, importers, and trade associations, to understand the implications of the MIP on business operations.

Comparative Analysis: Examining similar measures implemented in other countries and their outcomes to inform the decision-making process.

Potential Benefits:

Protection of Domestic Industry: By raising the benchmark for imported paper prices, local manufacturers may experience improved sales and profitability.

Encouragement of Local Production: A higher MIP could incentivize investments in domestic production capabilities, fostering growth in the local paper industry.

Job Preservation: Supporting local manufacturers through MIP may help in preserving jobs and promoting employment within the sector.

Challenges and Concerns:

Increased Consumer Prices: There are concerns that implementing an MIP may lead to higher prices for consumers, as domestic manufacturers may pass on the increased costs.

Compliance and Enforcement: Ensuring compliance with the MIP regulations and monitoring import pricing will be crucial to the effectiveness of the policy.

Next Steps:

The government is expected to finalize its assessment soon and will announce its decision regarding the implementation of the MIP. Stakeholders are encouraged to stay engaged and provide feedback during this critical period.

Conclusion: The assessment of the Minimum Import Price is a significant step towards ensuring the long-term viability of the paper industry in India. As the government weighs the potential benefits and challenges, it remains committed to fostering a balanced and sustainable market environment.

JK Paper has developed short-rotation clones of subabul and eucalyptus with a duration of not more than three years

JK Paper’s sustainable procurement strategy

The Pulp and Paper Times:

India ranks as the fifth largest market for paper and packaging, yet faces with a significant deficiency in fiber resources. This scarcity poses a challenge to the paper industry, compelling companies to place a premium on securing a steady supply of raw materials. In response to increasing demand, there has been a shift from a reliance solely on forest resources towards embracing agroforestry practices. This transition represents a significant evolution in the industry’s approach to sourcing raw materials, offering a more sustainable and diversified strategy for meeting the nation’s paper needs.

Procurement strategy

For over three decades, JK Paper has collaborated with farmers near its Odisha facility, a partnership that then commenced over two decades ago at Gujarat unit and was followed by the Telangana unit. These farmers have been cultivating fast-growing hardwood species such as eucalyptus, subabul, and casuarina, encouraged by JK Paper to plant across more than 81,000 acres(2023-24) in Gujarat, Maharashtra, Chhattisgarh, Madhya Pradesh, Andhra Pradesh, Telangana and Odisha. This initiative has not only expanded the Company’s resource base but has effectively lowered wood procurement expenses. JK Paper’s consistent plantation efforts have helped maintain a competitive edge over industry players, especially during periods of price volatility in the pulpwood market.

Strengths

State-of-the-art production centers: The Company made significant investments in state-of-the-art clonal production centers, leveraging cutting-edge technology to ensure consistent production of highquality planting material throughout the year. These advanced facilities enable the Company to maintain stringent quality standards and meet the demands of farmers and agricultural communities.

Research and development: Through dedicated research and development initiatives, the Company developed short-rotation clones of subabul and eucalyptus. These clones, with a duration of not more than three years, enhanced productivity, allowing farmers to generate higher annual revenues.Clonal cultivation emphasis: JK Paper emphasises the cultivation of quality clones, recognising the pivotal role they play in enhancing farm yields. By focusing on the production of superior clones, the Company empowers farmers to achieve greater agricultural productivity and profitability.

Certification validation: The attainment of prestigious certifications such as the Forest Stewardship Council (FSC) certification across all units underscores JK Paper’s commitment to environmental stewardship and responsible resource management. These certifications serve as a testament to the Company’s adherence to rigorous standards of sustainability and environmental conservation.

Challenges and counter initiatives, 2023-24

A number of factories of wood-based industries (plywood, MDF, particle boards etc.) were established near the vicinity our of plantations. This put a strain on raw material availability, forcing paper mills to address their raw material needs. JK implemented measures to navigate the crisis, including securing materials from forest tenders and exploring alternative species areas, while strategically importing chips to maintain a planned minimum quantity. These actions were aimed at ensuring resilience and exerting control over the domestic market by buying at the right cost.

Initiatives

The scarcity of wood led to the procurement of material from distant locations, increasing input costs and deteriorating quality, consequently increasing output costs.

The complexity and unorganised nature of the supply chain for wood, sourced from numerous farm fields, necessitated a high inventory.

The Company enhanced farmer engagement and mobilisation by directly procuring from farmers and offering logistical assistance in exchange for fair compensation.

JK Paper, including SPM, accessed raw material from 81,000 acres, the highest plantation area in its history.FSC® certification

The Forest Stewardship Council (FSC) is guided by a global network comprising over 1,000 individuals and member organisations representing diverse environmental, social and economic viewpoints. This international certification has become a benchmark for responsible organisations. JK Paper holds FSC® COC/ CW and FSC® - FM/COC certificates, ensuring that its products originate from forests managed to meet the social, economic, and ecological needs of present and future generations. Having acquired forest management and chain-of-custody certifications, JK Paper is equipped to manufacture FSC® COC certified products, including various types such as writing, printing, copier, bond, coated, and uncoated papers. In 2023-24, the Company sourced 100% of its raw materials from sustainable origins, categorised into two groups: FSC® 100% wood sourced from its meticulously managed group plantations, and verified controlled wood procured through suppliers located in regions like Odisha, Andhra Pradesh, Chhattisgarh, Gujarat, Maharashtra, Telangana and Madhya Pradesh, all accompanied by requisite documentation.

Tree plantation

The Company increased tree planting virtually every year across the last couple of decades, greening the environment, enhancing farmer livelihoods and enhancing resource security – a win-win proposition.

Clonal plantation coverage

The Company embarked on an innovative approach by developing the shorter maturity Subabul clone, reducing the rotation time from three years. This initiative enhanced productivity and sustainability across 85% plantations within a 200 km radius from the mill, ensuring a readily available raw material. Through extensive research, productive clones were cultivated, promising increased farmer incomes while delivering quality material with superior pulp yield in shorter cycles. Moreover, strategic associations and tie-ups with public sector undertakings and corporates were forged to streamline plantation efforts and wood procurement. Complementing these endeavours, advanced analytics optimised sourcing decisions and cost management, facilitating efficient operations and sustainable growth.

Mohit Paper Mills will achieve perfect point of cost of production after installation of evaporator and caustic soda plant

- After installing the BE and caustic soda plant, Mohit Paper can utilized its optimum or maximum production capacity

- Mohit Paper recorded decrease in sale (16.45%) (approx) due to reduce in the price of the paper in national market.

The Pulp and Paper TimesMohit Paper Mills Limited (MPML) was incorporated in the year 1992, is engaged in manufacturing of various kinds of paper like writing printing paper (color and white), MG Poster paper, kraft paper and others various quality papers as required on customer demand. MPML is agro based paper manufacturing Company means that it use agriculture products like bagasse and other agriculture product etc. for manufacturing of paper and we also use imported waste paper for manufacturing of paper to increase quality and strength of the manufactured paper.

At present MPML is using higher production capacity of the installed manufacturing capacity. Mohit Paper sold paper in form of reels, sheets and other size as required or demand of the customers.

The Company is adopting all the means for reducing the cost of production for increase the profit in the coming years the Company will achieve perfect point of cost of production after installation of evaporator and casting soda plant. The Company's cost of production of paper is higher than other paper company because of our small production capacity and using agro product for manufacturing of paper, because of the price of agro products is based on availability of bagasse and other agriculture products in the market.

“We expect for better and bright future of the Company. Our strategic objectives are to build a sustainable organization that remains relevant to the agenda of our stakeholders and creating growth opportunities for the employee and increase the wealth of the company for our stakeholders and members,” The annual report of Mohit Paper for FY 23-24 said.

RESULTS OF OPERATIONS AND STATE OF COMPANY'S AFFAIRS

Mohit Paper’s management is committed to aegis of the Company in every situation and also committed to achieving its objectives and goals. Presently the Company engaged in single segment i.e. manufacturing of paper, the management of the Company always keeps keen eyes on every situation/transitions of the Company. The Company is moving fast to maximization the wealth of shareholders and stakeholders of the Company.

At present the production capacity of the Company is 130 MT/per day and the Company is utilized it"s maximum production capacity. In the previous financial year 2022-2023 the Board of Directors decided to install 150 TDS Boiler and Evaporator ("BE") in the production line and caustic soda plant, the purpose to install this BE and caustic soda plant to increase the production with existing production capacity. The idea behind to install BE is that to increase the production of steam, power and caustic soda lye and result of this increment in steam, power and caustic soda, the production will be increased within the existing production capacity. After installing the BE and caustic soda plant, the Company can utilized its optimum or maximum production capacity. The Board supposed that this BE and caustic soda plant will be in used during FY 2024-2025 and which will be a mile stone for the Company.

HIGHLIGHTS OF FINANCIAL PERFORMANCE FOR THE FINANCIAL YEAR 2023-2024.

During FY 2023-2024, MPML has turnover (Net) of Rs. 18562.61/- lakhs as against previous figure of Rs. 22,216.50/- lakhs, the Company recorded decrease in sale (16.45%) (approx) due to reduce in the price of the paper in national market.

The Company has recorded 27% (approx.) downfall in market price of paper in the year 2023-2024. Further, during the financial year 2023-2024, other income of the Company has been increased to Rs. 640.05 lakhs as against previous year income of Rs. 411.03 lakhs (i.e. increase by around 55.72% during the financial year 2023-2024. However, due to reduction in price of paper as mentioned above, total income has shown a downfall during the financial year 2023-2024. The total income during financial year 2023-2024 is at Rs. 19,202.66/- and previous year income of Rs. 22,627.53/-lakhs.

The report further stated that The pulp and paper market in India was valued at USD 14.75 billion in 2023 and is projected to reach USD 35.57 billion by 2030, growing at a compound annual growth rate (CAGR) of 13.4% from 2023 to 2030. The market is expected to peak at USD 19.1 billion by 2033. Among the various segments within the paper industry, the packaging sector has performed particularly well, driven by applications in the pharmaceutical and FMCG sectors and boosted by e-commerce growth.

However, the Indian paper industry has faced challenges. The volume growth for FY 2023-24 is anticipated to decline to a range of 2-5%, compared to approximately 7% in FY 2022-23. Additionally, industry revenues are projected to decrease by about 7-10% in FY 2023-24, reflecting a drop in realizations. The packaging paper segment, which accounts for over 60% of total demand, has experienced reduced realizations since the second quarter of FY 2023 due to softened input prices and increased competition. This trend is expected to continue into FY 2023-24.

About the domestic market report said that India, a significant player in the global paper industry, ranks as the fifth-largest producer worldwide with an annual production capacity of 26 million tonnes. The Indian paper sector is projected to grow at a compound annual growth rate (CAGR) of 6%, anticipated to reach 27 million tonnes by the fiscal year 2023-24. The domestic market is diverse, comprising several key segments. The packaging sector, which accounts for 40% of total paper consumption, is poised for robust growth with a CAGR forecasted between 6-8%.

PAPEXPO 2025: Emami Paper, West Coast, Jani, Three M, and Satia to Exhibit Paper and Packaging Solutions, with Support from FPTA, IPPTA, and IIP

- India’s first dedicated exhibition for the paper industry, from June 6 to 8, 2025, at HITEX Exhibition Centre, Hyderabad

- Over 100 national and international exhibitors will participate, showcasing the latest innovations and product offerings across paper manufacturing, converting, printing, packaging, and recycling.

The Pulp and Paper Times | Hyderabad, May 28, 2025:

The Paper Foundation is set to host PAPEXPO 2025, India’s first dedicated exhibition for the paper industry, from June 6 to 8, 2025, at HITEX Exhibition Centre, Hyderabad. This landmark three-day event will bring together the entire value chain of India’s paper industry under one roof, making it one of the largest and most comprehensive industry gatherings in the country.

Guest of Honour will inaugurate the exhibition on June 6 at 10:00 AM, eminent guest are as Dr Ajay Satia – Satia MD, Mr Soumyajit Mukherjee – CMO Emami Paper mills , Mr Nataraj – IIP Deputy Director , Dr. Suresh kumar Singhal – President , FTCCI, Mr Sohanlal Dayama – Prompt Packaging , Mr Rushabh Shah – MD Three M Paper Boards ltd , MR. Abiali Jani – Director Jani Sales , will grace the occasion .

PAPEXPO is being supported by esteemed industry bodies including the Indian Institute of Packaging (IIP), Indian Pulp and Paper Technical Association (IPPTA), and the Federation of Paper Traders Associations of India (FPTA).

Over 100 national and international exhibitors will participate, showcasing the latest innovations and product offerings across paper manufacturing, converting, printing, packaging, and recycling. The Expo is expected to draw over 15,000 visitors over three days.

Emami paper , West Coast, Satia Industries , Jani sales ,shah papers, Three M Papers Board Pvt ltd , prompt packaging , Vijayanand speciality , Classic papers, Krishna Prabhas will showcase premium specialty paper, sustainable packaging solutions, eco-friendly innovations, and advanced printing technologies. India’s top paper manufacturers and traders will also mark their presence, including TIRUMALA BALAJI PAPER PRIVATE LTD , HYPER PACK ,SRI AYYAPAN FINE ART , KLM PACKAGING , SONA PAPERS , reinforcing PAPEXPO’s position as a must-attend event for stakeholders in the sector.

The exhibition will have exhibitors from segments such as Paper and pulp manufacturers, Paper product producers, Packaging and corrugation industry players, Publishers and printers, Importers, exporters, and traders, Machinery and technology providers. Exhibitors will predominantly hail from major paper-producing states such as Maharashtra, Gujarat, Tamil Nadu, and West Bengal, along with international participants, promising a truly global experience.

PAPEXPO is set to attract key decision-makers from paper mills, trading houses, the packaging sector, publishing industry, and paper-based product manufacturers. Visitors are expected from across India, with significant footfall anticipated from Andhra Pradesh, Karnataka, Maharashtra, Tamil Nadu, Chhattisgarh, Odisha, Madhya Pradesh, and Kerala.

India’s per capita paper consumption stands at a modest 15–16 kg, compared to the global average of 57 kg. A major reason for this gap is the widespread myth that paper usage leads to deforestation. PAPEXPO and the Paper Foundation aim to dispel such misconceptions by highlighting that most Indian paper mills use recycled fibre and cultivated trees. The industry promotes agroforestry, increasing green cover and supporting livelihoods. Also reinforce the fact that paper is among the most recyclable and sustainable materials available today. The expo will act as a powerful platform to raise awareness about the environmental and economic advantages of sustainable paper usage.

The industry is also seeking policy support from the Telangana Government, including the creation of a dedicated Paper Industrial Park, improved logistics infrastructure, and access to affordable utilities to enhance competitiveness.

The Paper Foundation, the force behind PAPEXPO, is committed to promoting sustainable paper production, supporting agroforestry and circular economy initiatives, encouraging recycling and eco-friendly packaging and collaborating with global players to bring green innovation to India. Through PAPEXPO 2025, the Foundation envisions catalysing a nationwide conversation on the importance of paper as a sustainable resource and reinforcing India’s role as a global leader in responsible paper production.

Foundation strongly believes that the Indian Paper Industry must be encouraged and supported for better Indian Economy, trade and smooth supplies. Foundation supports ATMA NIRBHAR BHARAT for GOVERNMENT OF INDIA. In the 122nd Episode of "Mann Ki Baat" on 25th May, 2025, Modi Ji has emphasised the importance of recycling of Paper and its good impact on the environment and how by waste collection and recycling, the Indian Paper Industry is supporting the country.

Please connect for Stall Bookings:

Mr. Nirmal Kuhad: 9347001275

Mr. S. Dayaker Reddy: 7021220085

Email: papyrusexpo@gmail.com

Price hike in packaging board and duplex amid low demand and a substantial drop in new orders for kraft paper

-There is a consistent gap of Rs. 8–8.5 per kg between the cost of waste paper and the selling price of finished craft paper

-Prices of duplex boards were raised by Rs. 2–2.5 per kg, and Kraft paper rates in Western Uttar Pradesh and Northern India saw a Rs. 2 per kg hike-Kraft waste paper rates in Morbi, Gujarat, dropped by Rs.1 per kg and are now at Rs.18,500 to Rs.19,000 per metric ton, due to poor demand and a payment shortage in the industry

The Pulp and Paper Times, May 20, 2025The Indian Kraft paper and packaging board sector, particularly the duplex board segment, continues to face significant headwinds, with market conditions remaining weak for the past 8–9 months. Industry insiders report sustained low demand, production cuts, and declining profitability.

According to a recent update shared by Indian Recovered paper Traders Association (IRPTA) president Mr. Naresh Singhal, most paper mills are operating only 18–20 days per month due to a lack of demand, with regular 5-day shutdowns now routine for many mills. Despite attempts to stimulate sales through flexible payment terms, dealers are hesitant to stock inventory.

However, current market behavior tells a different story. Dealers in SBS and FBB grades are struggling due to competition from cheaper imports, particularly FBB coming in at lower rates from abroad. After the May 18 meeting, prices of B-grade mills of duplex boards were raised by Rs. 2–2.5 per kg, and Kraft paper rates in Western Uttar Pradesh and Northern India saw a Rs. 2 per kg hike. Yet these increases failed to impact the market significantly due to muted demand.

"We are compelled to increase the prices of Virgin Packaging Board Grades due to significant rises in input costs and currency fluctuations. To mitigate the impact on production costs, we propose a price hike of INR 3,150/MT for Virgin Packaging Board Grades," Emami Paper Mills stated in its circular dated 12 May 2025.

ITC-PSPD informed its channel partners that the rising cost of raw materials and the current difficult market phase are impacting operations. "To partially mitigate this impact, we are announcing a price increase of INR 3,000 per MT, effective from 15 May 2025, applicable to all Virgin Fibre-based products. Kindly take note and communicate this to all customers and associates accordingly."

“There is a consistent gap of Rs. 8–8.5 per kg between the cost of waste paper and the selling price of finished craft paper,” Mr. Singhal stated, adding that such margins are unsustainable for mill operators.

Talking to The Pulp and Paper Times, Mr. Pankaj Mishra, Head of Sales & Marketing at Vamshadhara Paper Mills, said, the current situation in the Kraft paper industry is quite challenging. Demand has significantly weakened, leading to a substantial drop in new orders. Many manufacturers are struggling to maintain consistent order volumes, resulting in an oversupply of finished goods. This overproduction, combined with sluggish market activity, has put pressure on inventories and cash flows. At the same time, there is a notable shortage of raw materials, further complicating production planning and operational efficiency. The imbalance between supply and demand, along with raw material constraints, is creating a difficult environment for Kraft paper producers to sustain profitability and stability.

In a webinar held by the Paper Merchant Association of Delhi on May 18, stakeholders discussed the long-term future of the sector. The Indian Recovered Paper Traders Association also conducted an internal survey, where 80% of participants expressed confidence that craft paper and duplex boards would dominate demand in the near future compared to other grades.

May is typically a peak collection month for waste paper, fueled by increased availability of used books, newspapers, and notebooks. Despite this, domestic waste paper rates have not dropped as expected, primarily due to reduced imports and mills relying more heavily on local materials. With Delhi temperatures soaring to 45–50°C, waste collection activities are expected to decline until early July.

Looking ahead, industry insiders do not foresee major price movements before July 10. “The market may stay stable or fluctuate within a narrow range of 2–3%,” said Mr. Naresh Singhal, citing limited demand and slow payment cycles across the supply chain.

“The demand is expected to remain weak for the time being, and prices are showing significant fluctuations. Because of this instability and uncertainty in the market, it is difficult to make any firm commitments or predictions about when demand might improve or prices might stabilize. The current situation requires careful monitoring, as the unpredictable nature of price movements makes it challenging to plan or forecast with confidence,” Mr. Pankaj Mishra added.

In conclusion, while the long-term outlook for the packaging segment remains cautiously optimistic, immediate conditions continue to challenge both producers and traders. The sector now watches mid-July as a potential turning point for recovery.

Tariff Impact:

On the Trade Tariffs, Mr. Mishra said, “The imposition of tariffs on Chinese paper exports to the United States is expected to have ripple effects across the global paper market. As access to the U.S. market becomes more restricted and less profitable, Chinese paper mills will likely seek alternative outlets for their excess production. This could result in a surge of low-cost paper being redirected to other Asian markets, particularly price-sensitive countries like India. Such a move would intensify competition and significantly increase the supply in these regions, potentially driving down prices and putting pressure on local manufacturers. In the long term, this oversupply could destabilize the regional paper industry, leading to margin compression and financial strain on domestic producers”

Mr. Mishra further said, that India relies heavily on imported waste paper to meet its raw material needs for the paper industry. A significant portion of this waste paper comes from countries like the United States. If India were to increase tariffs on goods imported from the U.S., it could prompt a retaliatory response from the U.S., leading to higher tariffs on exports from the U.S. to India, including waste paper. This would make the import of waste paper more expensive for Indian manufacturers. As a result, the increased costs could lead to higher prices for paper products in India, potentially disrupting the market and affecting both producers and consumers. The higher import costs may also impact the competitiveness of Indian paper products in the global market.

No immediate impact, but Punjab paper mills stay cautious amid Indo-Pak strain, potential supply chain disruptions

- Punjab hosts around 35–40 paper mills, which could all feel the strain if the tensions persist

- Mills have been asked to switch off all outdoor lights and operate machines using minimal lighting

- The rates for waste Kraft paper have been reduced by ₹800 to ₹1,000 per metric ton

The Pulp and Paper TimesIn light of the ongoing Indo-Pak tensions, concerns are rising over their potential impact on the paper industry in Punjab. The Pulp and Paper Times reached out to industry insiders to understand the situation on the ground.

As of now, there has been no immediate effect on paper mills in Punjab. “Currently, there’s no government advisory to halt production or completely shut down paper mills,” Mr. Harish Jindal of Nachiketa Papers Mill informed The Pulp and Paper Times. However, the government has issued advisories requiring markets and shops in Chandigarh and the Tri-City area to close by 7 p.m., which is indirectly affecting operations.

“If working hours are reduced, the collection of waste paper will also decline. If this continues for a longer period, we may face shortages, leading to price increases,” Mr. Jindal explained. While there is no advisory to stop paper mill operations at night, mills have been asked to switch off all outdoor lights and operate machines using minimal lighting.

A key concern is the disruption in the supply chain of raw materials. “We import raw material from regions like Jammu and Srinagar. With the current situation, truck movement from these areas has stopped, impacting waste paper supply by an estimated 5–10%,” the spokesperson said. This is expected to push up waste paper prices in the coming days, although the exact increase is yet to be determined.

“There’s a possibility that the government may ask plants to halt operations for a few days,” Indian Recovered paper Traders Association (IRPTA)’s president Mr. Naresh Singhal revealed. While no official order has been issued yet, the industry is bracing for potential disruptions.

“There has been no government advisory instructing mills to cut back production or halt operations at night,” Mr. Gill of the SN Paper clarified. When asked about the possibility of future restrictions, they added, “It’s difficult to say right now.”

Concerns over raw material shortages and potential increases in waste paper prices have also been circulating in the industry. However, SN Paper reassured that there are no such challenges at the moment. “Everything is safe,” the representative stated.

SN Paper currently operates two plants with a combined capacity of 300 tons, and according to the management, production continues as usual.

On the finished paper side, the industry is already grappling with overcapacity and reduced demand. “If raw material prices rise, production costs will go up, but since factories are running below capacity, the demand for finished paper may not absorb the cost hike easily,” Mr Harish Jindal noted.

Punjab hosts around 35–40 paper mills, which could all feel the strain if the tensions persist. Some mills are also in the process of installing new machinery, adding further pressure to manage costs and operations during this uncertain period.

The coming days will be critical in determining how the situation unfolds, and the industry is closely monitoring developments.

About Demand

The impact isn’t limited to Punjab alone. “The slowdown is being felt across India — from western Uttar Pradesh to Gujarat and even the southern states like Karnataka,” an industry representative explained. Reports indicate a marginal dip in prices, with finished paper products seeing a drop of about ₹0.50 to ₹1. However, the slowdown in demand is evident across the country.

“The market is slow all over India,” Mr. Naresh Singhal noted, adding that seasonal factors are also at play. May and June, traditionally slower months due to school holidays and summer vacations, are seeing lower consumption. Families from the lower and upper middle classes alike are traveling — some to visit relatives in states like Bihar and Uttar Pradesh, while others head for tourism.

Tourist destinations like Srinagar have seen a complete halt, and pilgrimages to popular sites such as Vaishno Devi have sharply declined. While Uttarakhand remains relatively safe, the Char Dham Yatra has witnessed lower footfall compared to previous years. “In the first four to five days, about 400,000 pilgrims visited, but numbers have since dipped,” he said.

Waste Paper Scenario:

The Kraft paper industry in western U.P. and much of North India has been significantly affected by the ongoing Indo-Pak tensions.

Demand for finished Kraft paper has dropped in western U.P. mills over the past 10–12 days. To sustain sales, Kraft paper mills in the region have offered price discounts as well as relaxed payment terms. However, despite these measures, sales have not yet recovered to previous levels.

In this scenario, the price of finished Kraft paper has decreased by ₹1,000 to ₹1,250 per metric ton, accompanied by easier payment terms. This payment relaxation has led to a shortage of funds in the industry, which may result in delayed payments to waste paper suppliers.

Due to the decline in sales, the demand for waste paper has also fallen. To match the price cuts in finished Kraft paper, the rates for waste Kraft paper have been reduced by ₹800 to ₹1,000 per metric ton.

According to market reports and my personal assessment, the current conditions do not appear likely to improve over the next 10–15 days., Mr. Singhal said.

Sino-U.S. trade tensions are casting a shadow over the development prospects of China's paper industry, prompting paper giants to shift strategies

Lee & Man Paper plans to invest resources in the pulp business, while Nine Dragons will push forward its raw material expansion plans.

The Pulp and Paper TimesIn 2024, the macro-economy continued to face downward pressure with consumer demand remaining weak. The paper manufacturing industry in China, however, while absorbing excessive capacity and pulp price fluctuations, demonstrated resilience. Benefitting from a series of government stimulation policies such as cutting reserve requirement ratio, lowering interest rate, and boosting consumption, downstream demand gradually warmed up, resulting in a general recovery of paper manufacturing companies during the year.

China’s economy, driven by the stabilizing growth policies and further structural reforms, showed a mild turnaround with moderate recovery in domestic consumption. In addition, benefited from the export growth of end customers on top of the peak season factor, the demand for packaging paper improved moderately, driving the packaging paper industry sentiment from the trough to gradual recovery. Despite this, the overall consumer confidence in the market has yet to be fully restored, and the effective consumer demand remained insufficient.

Looking back at 2024, with new pulp production capacity being released in mainland China, pulp price remained unstable generally. Regarding the paper manufacturing industry, although players speeded up destocking during the year, market demand continued to be weak. In addition, as the U.S. presidential election during the year brought uncertainties, the industry’s overall performance was affected.

FUTURE OUTLOOK

Looking ahead to the second half of the financial year, Nine Dragons Paper Group will encounter both opportunities and challenges. The Chinese government’s special campaign to boost consumption will continue to unleash consumption potential, which will in turn support the demand in the packaging paper industry. Nonetheless, the continued release of new capacity, the gradual recovery of the economy and consumption, and increasingly tense international relations will all affect market demand and supply. However, we strongly believe that the environmental trend of “replacing plastic with paper” and the demand stimulus of “replacing the old with the new” will present opportunities to the paper manufacturing industry. Meanwhile, the Group is determined to deepen its strategy of pulp and paper integration, which will further enhance its cost control capabilities and brand competitiveness, consolidating the foundation of profitability and solidifying the leading position of the Group in the industry.

Looking ahead at 2025, while ongoing Sino-U.S. trade tension is casting a shadow over the development prospects of enterprises, new opportunities have emerged at the PRC government policy – “export goods for domestic sales”. China has clearly proposed earlier to vigorously boost consumption and enhance investment efficiency for realizing the strategic goal of expanding overall domestic demand. Such stimulus policies are expected to help promote consumer spending, continuously improve consumption sentiment, in turn drive increase in demand for paper products. Moreover, as the paper manufacturing industry is close to the end of the capacity release cycle, supply is expected to gradually stabilize, meaning the industry should see the supply-demand balance restore and moderate growth in its performance.

According to Lee & Man Paper Group, it will seize the opportunities brought about by favorable policies to actively promote development of its domestic sales business. It will, via pursuing technological upgrades, push to improve production efficiency of its paper-making equipment, aiming to further reduce costs and widen profit margins. It will also strengthen product research and development to match the diverse needs of customers, thereby bolster the market competitiveness of its products.

As per the interim review of Lee & Man Paper for the year ended on 31st December 2024, “The pulp business is an important part of the Group’s vertically integrated production setup. We will continue to invest resources in technological upgrades and optimization of our pulp production equipment, aiming to increase pulp sales as well as provide a stable supply of raw materials to our tissue paper business, thereby enhance overall production efficiency and maximize profits.

“Looking ahead, the Group will insist on implementing a prudent business strategy, actively identify growth opportunities in the paper manufacturing industry, continuously expand and refine the layout of each business segment in its integrated industrial chain. It will also strengthen its profit base, enhance operational efficiency, so as to maintain its competitiveness in the market,” Lee & Man Paper said.

As per the interim review of Nine Dragon Paper for the six months ended December 2024, The Group will push forward the raw material expansion plans in an orderly and steady manner, and strive to strike a proper balance between production and sales. It will also ramp up technological innovation and resource integration, and further promote the standardization and uniformity of pulp and paper production quality. The Group will continue to achieve sustainable supply of exemplary quality paper that embodies the characteristics of Nine Dragons Paper, while raising the proportion of high value-added products. At the same time, the Group will utilize big data to promote the quality and efficiency enhancement measures by pursuing prudent financial strategies. Furthermore, it will strengthen green and compliant operations to achieve high-quality and sustainable development.Revenue:

Nine Dragons Paper Group achieved a revenue of approximately RMB33,464.6 million for the Period, representing an increase of approximately 9.3% as compared with the corresponding period last year. The major contributor of the Group’s revenue was still its packaging paper business, including linerboard, high performance corrugating medium, coated duplex board and bleached folding boxboard, which accounted for approximately 90.9% of the revenue, with the remaining revenue of approximately 9.1% generated from its printing and writing paper, high value specialty paper and pulp products.

For 2024, Lee & Man Paper Group recorded total revenue of HK$26.0 billion, representing an increase of 4.2% from that of the previous year, while the profit for the year increased by 17.6% to HK$1.4 billion as compared with that for the previous year. The earnings per share for the year were HK30.56 cents (2023: HK24.39 cents).

Facing changes in market supply and demand, Lee & Man Paper Group insisted on actively promoting integration of its industrial chain to ensure raw materials supply and control costs, and ultimately improve gross profit. By flexibly adjusting the production and sales between pulp and paper manufacturing businesses, we were able to enhance operational efficiency and effectively drive steady growth of profitability overall.

Lee & Man Paper’s pulp production lines in Chongqing, Jiangxi, and Guangxi, in operation since 2023, operated smoothly during the year. The vertically integrated business model has enabled the Group to reap economies of scale, further lowering costs and in turn boosted profitability and profit margins during the year. As for the overseas production bases in Vietnam and Malaysia, they continued to demonstrate cost advantages and recorded considerable profits. The overall gross profit margin of the Group for the year was 12.0%, up by two percentage points year-on-year.

Nine Dragons Paper continued to optimize its raw material expansion plans, and gradually utilized big data to facilitate scientific and innovative management and comprehensively launch the quality and efficiency enhancement measures, thereby effectively enhancing its cost control capabilities and operating efficiency. At the same time, the Group closely tracked the market dynamics of raw materials and finished product of paper, and timely adjusted its production and sales strategies to maximize profitability. The Group’s fundamentals continued to improve and profitability substantially climbed. The gross profit for the Period increased by 18.1% year-on-year, while net profit after tax also surged by 124.9% year-on-year. In addition, we further improved the risk management system and kept working capital, cash flow and exchange rate fluctuation risks to minimum levels, solidly securing the robust development of the Group.

The majority of the Nine Dragons Paper’s revenue continued to be realised from the China market, in particular from the linerboard, high performance corrugating medium, coated duplex board and bleached folding boxboard sectors. For the Period, revenue related to China consumption represented 89.4% of the Group’s total revenue, while the remaining revenue of 10.6% represented sales recorded in other countries outside China.

An overview of the paper and paperboard packaging industry in India

- The long-term demand outlook for paper in the Indian market remained moderately positive, due to the relatively low per-capita consumption compared to global averages.

- The flexible packaging market in India is projected to expand by USD 15.57 billion from 2023 to 2028, with a CAGR of 12.69%.The Pulp and Paper Times

Indian paper industry overview

The pulp and paper market in India was valued at USD 14.75 billion in 2023 and expected to reach USD 35.57 billion by 2030, growing at a CAGR of 13.4% during the time spanning 2023 to 2030. The market value of the Indian paper industry was forecast to peak USD 19.1 billion in 2033. Among the various business segments within the paper industry, the packaging industry fared well across application segments like the pharma sector and FMCG, catalysed by e-commerce.

The Indian paper industry’s volume growth is expected to have declined to a 2-5% range in FY 2023-24 as against ~7% in FY 2022-23. Besides, the industry’s revenues were projected to have declined by ~7-10% in FY 2023-24 amid a decline in realisations. The realisation levels in the packaging paper segment (more than 60% of total demand) witnessed a decline starting from the second quarter of FY2023, as the input prices and rising competition softened. This trend continued in FY 2023-24 as well.

Outlook

The long-term demand outlook for paper in the Indian market remained moderately positive, due to the relatively low per-capita consumption compared to global averages. The implementation of the New Education Policy (NEP) is expected to stimulate demand for printing and writing paper. The increasing use of specialised and traditional packaging in FMCG, healthcare, e-commerce, pharmaceuticals, and consumer industries is expected to drive demand; a focus on innovative and visually appealing packaging, and ongoing transition from plastic to paper-based packaging in the FMCG and food product sectors is expected to catalyse demand as well. (Source: Maximize Market Research, ICRA, Financial Express)

India paper and paperboard packaging industry

The India paper and paperboard packaging market was valued at USD 12.87 billion in 2024 and is forecast to reach USD 17.74 billion by 2029, growing at a CAGR of 6.63% between 2024 and 2029. The growth of the market is dependent on a shift towards flexible packaging on account of high logistics costs, growing retail demand, and increase in the demand for digitally printed packaging.

India has more than enough capacity to produce nearly all grades of paper, yet large imports are threatening the financial health of many mills. Of the over 900 paper mills in the country, only 553 are currently operational. Imports, particularly paper and paperboard from ASEAN countries, enter India duty-free under the ASEAN-India Free Trade Agreement. Additional duty concessions from ASEAN and Korean FTAs, as well as tariff concessions to China under the Asia Pacific Trade Agreement (APTA), have further stimulated paper imports. Subsidies provided to paper mills in some of these countries give them a pricing edge over Indian mills.

For the fiscal year 2023, India exported paper and paperboard products worth around USD 3.04 billion. Conversely, the export value of pulp and waste paper was the lowest at USD 3.59 million. In 2023, India’s per capita paper consumption was about 15 kg. The Indian paper industry contributes 5% to global production, suggesting significant potential for growth.

The flexible packaging market in India is projected to expand by USD 15.57 billion from 2023 to 2028, with a CAGR of 12.69%. There is a growing demand for paper, particularly in the packaging of FMCG products and ready-to-eat foods. Packaging-grade paper represents 55% of the primary types of paper produced in the domestic paper and paperboard industry. In FY 2023-24, the volume of packaging paper was expected to increase by 6-8%, driven by demand in the pharmaceutical and FMCG sectors. Meanwhile, the volume of writing and printing paper grew by a modest 3-5% due to increased digitalization.

The sector’s growth is fuelled by increases in e-commerce, food processing, pharmaceuticals, FMCG, manufacturing, and healthcare. Furthermore, various government initiatives, including ‘Make in India’, have positively influenced the packaging industry. The paper and packaging industry ranks as the fifth largest sector in the Indian economy. (Source: Mordor Intelligence, Technavio, Print Week India, Economic Times, Statista)

Wastepaper-based paper manufacturing in India

The demand for pulpable wood in India in FY 2022-23 stood at 11 million tons, which is expected to reach 15 million tons by 2024-25. The availability of the product is pegged at 9 million tons. However, India’s wastepaper collection/recovery is a mere 38% as against 68% in the US.

The paper industry uses wood, agro residues (such as straw and bagasse) and waste paper (imported as well as domestic) as input substrates for production. Currently, in the total production, the share of wood, agro and waste paper-based mills stand at 18%, 7% and 75% respectively. Imports of wastepaper grew by 11.62% in terms of quantity and 9.90% in terms of value in FY 2022-23.

Currently out of 125 newsprint mills in India, 46 have stopped the production of newsprint. The present domestic installed capacity of newsprint stands at 2.2 million tons. The imports of newsprint in the country for FY22 and FY 2022-23 stood at 0.61 million tons and 0.62 million tons respectively. Around 50% of the required newsprint in the nation was met through imports.

Writing and printing paper industry in India

The Indian writing and printing paper market was valued at USD 2660.00 million in 2021 and is expected to reach USD 4502.48 million by 2029, registering a CAGR of 6.80 % during the forecast period of 2022 to 2029. The market has expanded significantly in recent years due to the swift adoption of packaging solutions and an increase in home delivery services across various regions. Writing, printing, and specialty paper are essential for protecting and transporting a diverse range of goods. Demand for this paper from catalogues, books, notebooks, industrial printing, stationery, newspapers, magazines, business forms, packaging, and labelling is expected to fuel the growth of the writing, printing, and specialty paper in India. (Source: Data Bridge Market Research)

The above report on Indian paper and paperboard packaging industry has been extracted from Emami Paper Mills’ Annual Report 2023-24

Manufacturing activities at JK Paper have been disrupted due to a strike

The Pulp and Paper Times

JK Paper Limited is among the leading Paper and Packaging Board companies in India has informed National Stock Exchange about the disruption of manufacturing activities due to strike by the trade unions.

JK Paper in its filing said that strike has been called by the trade unions of a section of workers at Unit: CPM of the Company at Fort Songadh, Distt Tapi, Gujarat w.e.f. March 17, 2025. Due to this, the manufacturing activities of the said unit have been disrupted to some extent.

The Company Management is in discussion with the concerned Trade Unions to resolve the issue amicably as soon as possible and shall provide update on further developments.

Due to this, the manufacturing activities of the said unit have been disrupted to some extent, it added.

On the estimated impact on production, the company said it is at around 20 per cent less production than normal course.

Global and Indian packaging market overview

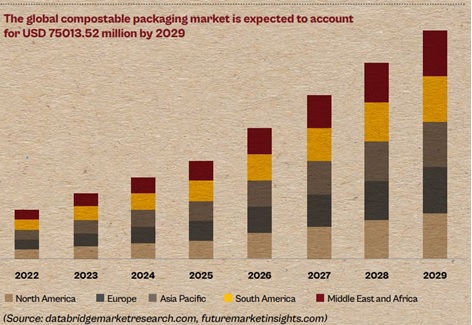

Global compostable packaging market and Indian paper and packaging market overview

-Europe is at the forefront of the compostable packaging industry, driven by increasing consumer awareness of the environmental impact of their purchases.

The Pulp and Paper Times

The global packaging market size is estimated at USD 1.17 Trillion in 2024, and is expected to reach USD 1.42 Trillion by 2028, growing at a CAGR of 3.9% during the time spanning 2023 to 2028.

On a regional basis, Asia emerged as the largest packaging market, recording sales of USD 470 Billion in 2023. North America followed with sales amounting to USD 270 Billion, and Western Europe registered a market size of USD 234 Billion.

Over the last ten years, steady growth in the global packaging market has been fuelled by shifts in substrate preferences, expansion into new markets and changes in ownership structures. Within the food sector, flexible packaging, highbarrier films and stand-up retort pouches are becoming more popular, challenging conventional packaging options such as metal tins and glass jars. Besides, with the transformation of the Internet of Things (IoT), RFID tags, QR codes and sensors, smart packaging solutions are becoming pivotal in the packaging industry.

Increasing retail sales are prompting manufacturers to develop innovative packaging to captivate consumers. Eye-catching and creatively designed packaging helps products stand out on retail shelves and attract consumer interest, thereby driving the adoption of advanced packaging solutions.

However, the growing use of non-recyclable, nonbiodegradable plastic packaging is contributing to higher carbon emissions, which could hinder growth. In response, major corporations like Amazon, Google, and Tetrapak are shifting towards net-zero carbon emissions goals, shaping their future investment strategies in capital.

Indian paper and packaging market overview:

The Indian paper and packaging market is projected to expand from USD 15.96 Billion in 2024 to USD 38.87 Billion by 2029, at a CAGR of 19.48%. The imports of paper and paperboards into India surged by 34%, registering ~19.3 Lakh Tonnes in FY23- 24, primarily on account of increased shipments from ASEAN countries. This influx has undermined the ‘Make in India’ initiative and adversely affected employment for around 500,000 farmers involved with the domestic paper industry through agro and farm forestry initiatives.

India possesses ample capacity to produce nearly all paper grades domestically, yet large imports are threatening the economic sustainability of many mills. Out of more than 900 paper mills, only 553 remain operational. The imports, largely from ASEAN under the ASEAN-India Free Trade Agreement, benefit from zero import duties. Additional import tariff concessions to China under the Asia Pacific Trade Agreement (APTA) and to ASEAN and Korean Free Trade Agreements (FTAs) have further intensified the competition. Subsidies provided by some of these countries to their paper mills offer them a cost advantage, further challenging the viability of Indian paper mills.

In FY22-23, India exported paper and paperboard products valued at around USD 3.04 Billion, while exports of pulp and waste paper reached a minimal USD 3.59 Million. Per capita paper consumption in India stood at an approximate 15 kg in the same year. The Indian paper industry, contributing to 5% of global production, shows significant potential for growth. The flexible packaging market in India is projected to expand by USD 15.57 Billion from 2023 to 2028, with a compound annual growth rate (CAGR) of 12.69%. There is a rising demand for paper, particularly in the packaging of FMCG products and ready to-eat foods.

Packaging-grade paper constitutes 55% of the primary types of paper produced domestically within the paper and paperboard industry. Expected growth for packaging paper volume was 6-8% in FY23-24, driven by the pharmaceutical and FMCG sectors. Meanwhile, writing and printing paper volumes increased by only 3-5%, affected by the shift towards digitalisation.

The expansion in the sector is fuelled by a significant increase in e-commerce, food processing, pharmaceuticals, FMCG, manufacturing and healthcare. Moreover, various government initiatives such as ‘Make in India’ have positively influenced the packaging industry. Currently, the paper and packaging industry ranks as the fifth largest sector in the Indian economy.

Global compostable packaging market overview

Compostable packaging provides an eco-friendly solution by offering sustainable materials that are easily broken down in home or industrial compost settings.

This alternative to single-use plastics helps to minimise landfill waste. The key driver for the growth of the global compostable packaging market is the increasing awareness of biodegradable and compostable packaging options. The demand for visually appealing products also presents opportunities for market expansion. Furthermore, innovative developments by manufacturers are helping to propel the growth of the compostable packaging market. The market is projected to grow from USD 103.39 Billion in 2024 to approximately USD 197.85 Billion by 2032, with a CAGR of 8.4% from 2023 to 2032.

On a regional basis, Europe is at the forefront of the compostable packaging industry, driven by increasing consumer awareness of the environmental impact of their purchases. Research indicates that over half of European consumers are prepared to spend more on sustainable products. Consequently, global companies are compelled to develop and adopt ecofriendly packaging solutions that help reduce waste disposal. In the United States, only 15% of the composting facilities process certain types of biodegradable packaging. About 55% of these facilities exclusively handle green waste, like yard debris and agricultural residues, while around 45% also accept food waste along with other biodegradable materials. Nearly 29% of the facilities are equipped to process food waste, and an additional 15% can handle both packaging materials and food waste.

As developing economies undergo rapid industrialisation and urbanisation, there is a rising consumer awareness and demand for sustainable packaging solutions. These markets often see an expanding middle-class population with increased environmental awareness, fuelling the adoption of compostable packaging materials.

Governments are placing greater emphasis on environmentally sustainable practices, leading to regulations and policies that encourage or require the use of compostable packaging materials. These efforts aim to reduce the environmental impact of traditional packaging and tackle issues associated with plastic waste. With governmental support, a favourable environment is being created for businesses to adopt compostable packaging solutions, encouraging a global shift toward ecofriendly alternatives. As governments actively advocate for sustainability, the compostable packaging market is experiencing significant growth, supported by a collective push toward a more environmentally responsible packaging ecosystem.

The above report has been extracted from Pakka Limited annual report for FY 23-24

Banganga Paper Mills boosts Q3 FY25 performance with advanced manufacturing capabilities, shifting to solar energy for substantial cost savings

- Banganga is well-positioned to meet the increasing demand for sustainable and high-quality paper products

The Pulp and Paper Times

Banganga Paper Industries Limited, one of the leading manufacturer and supplier of a diverse range of kraft paper, has announced its Q3 & 9M FY25 results.

Company has earned a total Income of Rs. 2079.15 Lakhs while Net Profit stood at Rs. 76.09 Lakhs in Q3 of FY25, in 9M, total Income of the company stood at Rs 3768.36 Lakhs, and net Profit Rs. 88.38 Lakhs

Commenting on the financial performance, Mr. Karbari Dathrak Chairman & Managing Director, Banganga Paper Industries Limited said, “We are pleased with our good performance in Q3 FY25, driven by our advanced manufacturing capabilities and the continued growth of our wholly owned subsidiary, Banganga Paper Mills. With a state-of-the-art facility producing over 100 metric tonnes of kraft paper daily, we are well-positioned to meet the increasing demand for sustainable and high-quality paper products. Our commitment to eco-friendly manufacturing, including the use of recycled materials and efficient resource management, remains a key differentiator in the industry. Looking ahead, we are confident in maintaining our growth momentum, leveraging our operational strengths and market opportunities to deliver continued growth in the upcoming quarters.”

During FY 23-24, the Company has achieved total revenue of Rs. 3,940.15/- thousand as compared to Rs. 5,520/- thousand in the previous financial year. Further, the Company has generated a Net Profit (after tax) of Rs. (218.92)/- thousand for the financial year ended March 31, 2024, as compared to the loss of Rs. 1,360.82/- thousand in the previous financial year 2022-2023. The Company is actively pursuing to be fully operational and pursue activities in consonance with the objectives for which it is established and taking necessary steps to effectively implement the same.

Sustainable energy adoption:

Banganga Paper Industries Limited has taken a significant step toward sustainable energy adoption. Its wholly owned subsidiary, Banganga Paper Mills Limited, has entered into a Power Purchase Agreement (PPA) with Livint Green Technologies Ltd. for the procurement of solar power under a captive power generation model.

As per the agreement, Livint Green Technologies Ltd., will develop, own, and operate a 2.5 MW DC groundmounted solar power plant at Karjat Village, Ahmednagar District, Maharashtra. This solar facility will supply clean energy to Banganga Paper Mills' manufacturing unit in Nashik, ensuring a reliable and costeffective renewable energy source.

To comply with captive power generation regulations, Banganga Paper Mills Limited will hold a 26% equity stake in the power-producing entity, while the remaining 74% will be retained by Livint Green Technologies Ltd. The project will be developed under a Build-Own-Operate model, ensuring long-term sustainability and operational efficiency.

Additionally, under a Wheeling and Banking Agreement, any surplus electricity generated from the solar power plant will be banked with the state’s power distribution company for later use. This strategic move will not only provide energy security but also enable Banganga Paper Mills to leverage carbon credits, reinforcing its environmental responsibility and commitment to green energy solutions.

The PPA has a minimum lock-in period of 15 years, with provisions for extension upon mutual agreement, demonstrating a long-term commitment to renewable energy and sustainable business practices.

By shifting to solar energy, the company will benefit from lower per-unit costs compared to current grid tariffs. With the present energy cost at Rs. 10.85 per unit, this initiative will lead to direct savings of approximately Rs. 2.30 to Rs. 2.50 per unit, as power is generated and distributed via the open grid for internal consumption. Additionally, the company is expected to receive a tentative government subsidy of around Rs. 1.50 per unit on captive consumption, further enhancing cost efficiency. Effective April 1, 2025, the company will begin realizing substantial energy cost savings through this initiative.

Banganga Paper Industries Limited (Formerly known as Inertia steel Limited) is one of the leading manufacturers and suppliers of a diverse range of Kraft paper. The company’s wholly owned subsidiary, Banganga Paper Mills, located in Dindori, Nasik, and operates a state-of-the-art facility spread across more than 10,000 square meters. With an installed production capacity of over 100 metric tonnes per day, the facility produces various types of corrugated papers with different GSM ranges, which are further used in the manufacturing of paper bags, paper cones, boards, and corrugated boxes. Additionally, it manufactures a wide range of craft paper, also available in various GSM ranges.

IRPTA proposes reduction in GST on Waste Paper in the upcoming Delhi budget

General Secretary Mr. Rajeev Sharma of 'Indian Recovered Papers Traders Association' Meets Chief Minister, Presents Suggestions

The Pulp and Paper TimesNew Delhi: A delegation of traders from Delhi met Chief Minister Rekha Gupta at the invitation of the government regarding the budget to be prepared with public participation. Among the delegation was Rajeev Sharma, General Secretary of the 'Indian Recovered Papers Traders Association' and a paper merchant.

Rajeev Sharma congratulated Rekha Gupta on becoming Chief Minister on behalf of the association and appreciated her initiative to consult traders and entrepreneurs before finalizing the budget. He expressed pride in the fact that a member of a business family has become the Chief Minister of Delhi and that, for the first time, traders have been invited to contribute to budget-making.

Demand for the Establishment of a Business Welfare Board

Rajeev Sharma urged the Chief Minister to establish a Business Welfare Board in Delhi, similar to other states, to ensure timely resolution of traders' issues.

Appeal for Relief in GST Cases

The association also proposed that the government immediately withdraw GST demands related to the COVID-19 period to provide relief to traders. Additionally, it was suggested that senior citizen traders should receive medical facilities from the government based on their GST contributions.

Participation in Waste Management

Rajeev Sharma highlighted the alarming situation of massive garbage dumps in Delhi and requested that his association be involved in their disposal. He emphasized that their participation could be a milestone in improving the city's waste management. He also urged the government to reduce GST on waste paper, as many underprivileged individuals, who play a significant role in keeping the city clean, depend on this sector for their livelihood.

Proposal to Make Delhi Beggar-Free

Rajeev Sharma suggested making Delhi a world-class city by eliminating the growing number of beggars at every major intersection. He pointed out reports suggesting that some beggars are brought in on contract from outside the city and called for concrete steps to address the issue.

Chief Minister Rekha Gupta attentively listened to the traders' demands and assured them that the government would work towards viable solutions for their concerns.

New partnerships help Amcor move toward 30% recycled content across its portfolio by 2030

- Amcor invest approximately $100 million in research and development to help drive long-term growth.

The Pulp and Paper TimesAmcor is a global leader in developing and producing responsible packaging solutions across a variety of materials for food, beverage, pharmaceutical, medical, home and personal-care, and other products.

Amcor works with leading companies around the world to protect products and the people who rely on them, differentiate brands and improve supply chains. The company offers a range of innovative, differentiating flexible and rigid packaging, specialty cartons, closures and services. The company is focused on making packaging that is increasingly recyclable, reusable, lighter weight and made using an increasing amount of recycled content. In fiscal year 2024, 41,000 Amcor people generated $13.6 billion in annual sales from operations that span 212 locations in 40 countries.

“By integrating sustainable practices into every aspect of our operations, we are ensuring our products contribute to a more sustainable future and we are focused on developing solutions that have a lower carbon footprint and support a circular economy for packaging. Currently, almost all of our Rigid Packaging and cartons portfolios are recyclable, compostable or reusable, and in Flexible Packaging, approximately 90% of our portfolio is recyclable or has a recycle-ready alternative. We also continue to increase the use of recycled material in our packaging solutions and we are confident in achieving our goal of 30% recycled content usage across our product portfolio by 2030,” Mr. Graeme Liebelt, Chairman of Amcore said in the annual report for FY 2024.

Peter Konieczny, Chief Executive Officer at Amcor said in the report, “Amcor demonstrated significant resilience through a challenging 2023 calendar year and made substantial Progress through fiscal 2024, delivering a year of strong margin expansion with earnings momentum building through the year. Our disciplined focus on managing costs resulted in annualized cost savings of more than $440 million, helping mitigate the impact of inflation and variable customer and consumer demand. We are encouraged by a return to volume growth in the fourth quarter of fiscal 2024 after a period of soft customer demand,”

Twelve months ended June 30, 2024 : Net sales of $13,640 million were 7% lower than last year on a reported basis, including a favorable impact of approximately 1% related to movements in foreign exchange rates, an unfavorable impact of approximately 1% related to items affecting comparability, and an unfavorable impact of 1% related to the pass through of lower raw material costs of approximately $220 million.

Strategic investment:

Annually, Amcor invest approximately $100 million in research and development to help drive long-term growth. We support the next generation of innovators through Amcor Lift-Off program, whose fiscal 2024 winners include technologies leveraging artificial intelligence for advancements in waste management.Amcor also invest in partnerships to build capacity and drive demand for recycled materials, which is a crucial step in closing the loop to create a circular economy for packaging. In fiscal 2024, Amcor achieved its goal of using 10% postconsumer recycled resins in product portfolio, one year ahead of 2025 target.

“We continue developing new partnerships with recyclers and suppliers of recycled materials to ensure strong supply pipelines across our global markets. One such partnership will enhance our ability to purchase mechanically recycled polyethylene resin for use in flexible packaging films across North America, while another will enable us to source additional advanced recycled material beginning in 2025 that will enable packaging solutions using recycled content for food and healthcare customers in key markets in Asia Pacific. Combined, these partnerships will help Amcor take another important step toward achieving our target of using at least 30% recycled content across our portfolio by 2030,” Mr Peter Konieczny added.

Product innovation:

Amcor annual report stated that bringing new solutions to market requires close partnership with our customers. Some notable collaborations in fiscal 2024 include a number of customer launches of our AmFiber™ solutions across regions, the introduction of our curbside-recyclable AmFiber™ Performance Paper packaging in North America, as well as our partnership with an iconic chocolate brand to transition to 50% food-grade recycled packaging in Australia.

“Additionally, we marked several firsts, including launching our first-ever one-liter carbonated soft drink stock bottle made from 100% post-consumer recycled (PCR) material. We partnered with a cosmetics, skin care and personal care pioneer in China to launch AmPrima™ Plus refill pouches for its line of shower gels, marking the first refill pouch with recycle-ready material. And, we announced the introduction of more than 90% recycled tin into our premium tin capsules and sparkling foils range.” The report added.

Q1 results ended 30th September 24:

The report said, “Our fiscal 2025 year is off to a very good start with broad-based improving customer demand across many end markets. Our teams continue to position Amcor to win with our customers, which resulted in our third consecutive quarter of sequential improvement in volumes. Overall volumes for the fiscal first quarter were up approximately 2% compared with 1% in Q4. As expected and called out in August, volumes remained weak in healthcare in North American beverage, which unfavorably impacted overall company volumes by approximately 2%.”

So across the balance of the business, overall volumes increased by 4% over the September quarter. Price/mix had an unfavorable impact on sales of approximately 3% primarily driven by continued destocking in higher-margin healthcare categories as expected, and as noted on our August earnings call.

Economic and Market Conditions

After experiencing more challenging market conditions in calendar year 2023 which impacted both fiscal year 2023 and fiscal year 2024 with softer consumer and customer demand and increased destocking, customer volume trajectory sequentially improved in the second half of fiscal year 2024 with a return to volume growth in the fourth quarter of fiscal year 2024. The improvement in the second half of fiscal year 2024 is attributed primarily to the abatement of destocking across many end markets and higher customer demand in parts of our business. While we continue to be impacted by softer consumer demand and customer order volatility in certain markets, and higher inflation in certain areas, such as labor costs, we have flexed our cost base to adjust to market conditions. Higher inflation, especially in Europe and the United States over the last two fiscal years, has led central banks to rapidly raise interest rates to dampen inflation which has resulted in higher interest expense on our variable rate debt, particularly on U.S. dollar and Euro denominated debt.