ICFRE: Dependence of paper manufacturing on forests gets minimized to a certain level as of today

ICFRE: Dependence of paper manufacturing on forests gets minimized to a certain level as of today

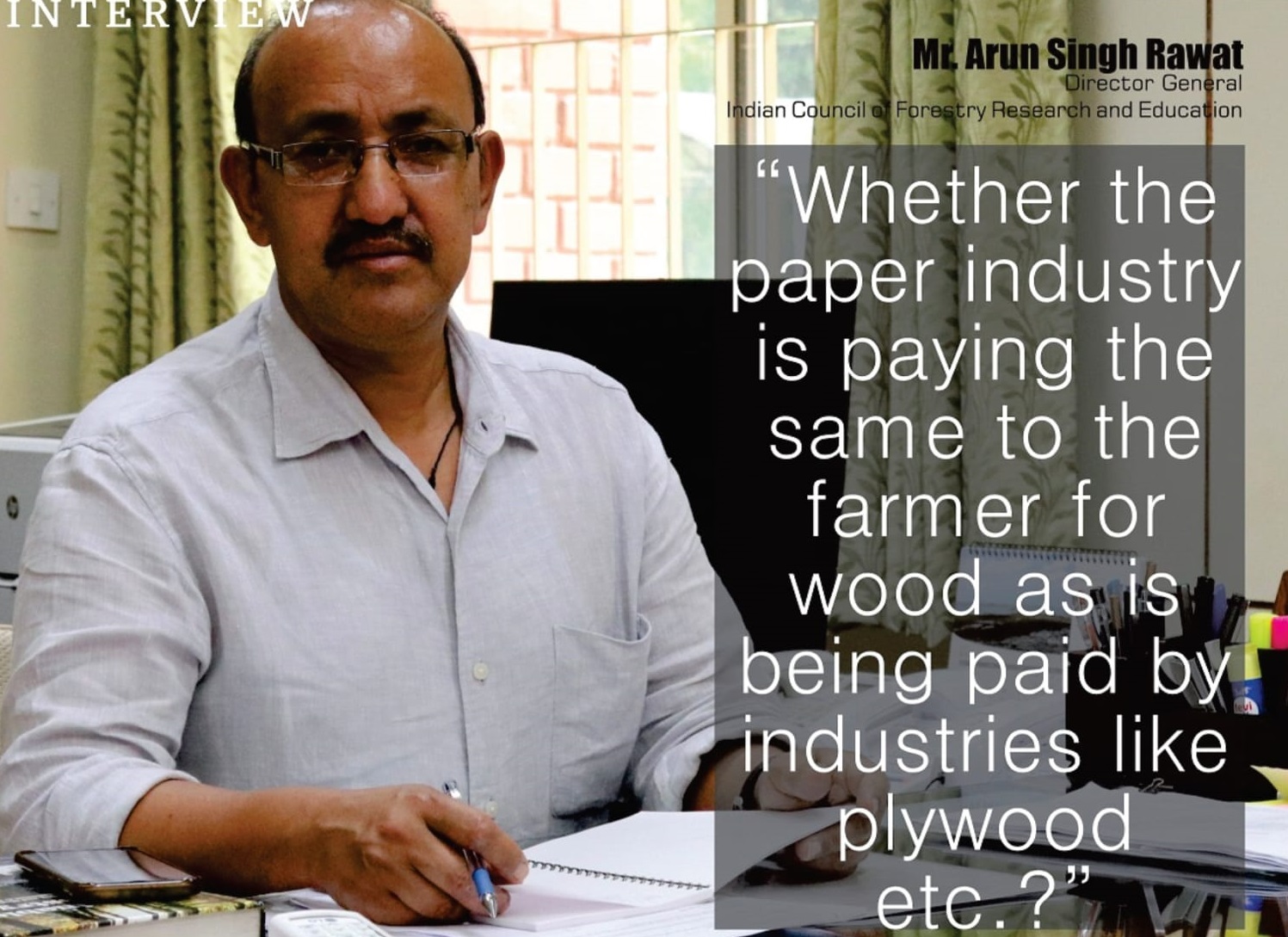

- Whether the paper industry is paying the same to the farmer for wood as is being paid by industries like plywood etc.?

- Vitro propagation could be the key of mass clonal propagation of desirable genotypes.

- Paper industries by their ownself and by promoting farmers may grow those high yield varieties for sustainable supply of raw material.

The Pulp and Paper Times recently interacted with Mr Arun Singh Rawat, Director General – Indian Council of Forestry Research and Education (ICFRE), Dehradun. Here is his full interview:

July 2022 | The Pulp and Paper Times:

Q: Please give a small introduction of the Indian Council of Forestry Research and Education (ICFRE).

Under the aegis of Ministry of Environment, Forest & Climate Change, the Council has a pan India presence with its nine Regional Research Institutes and five Centers in different bio-geographical regions of the country.

Presently, ICFRE with its Headquarters at Dehradun is an apex body in the national forestry research system that promotes and undertakes need based forestry research extension at National level.

Each Institute of Council is directing and managing research, extension and education in forestry sector in the states under their jurisdiction. The regional research Institutes are located at Jodhpur, Dehradun, Shimla, Hyderabad, Coimbatore, Ranchi, Bengaluru, Jorhat and Jabalpur, and the centers are at Agartala, Aizawl, Allahabad, Chhindwara and Visakhapatnam.

If we go back in time, the journey of ICFRE was initiated way back towards the end of the nineteenth century with the advent of scientific forestry in India and the establishment of the Forest School in Dehradun in 1878. In 1986 the Indian Council of Forestry Research and Education was formed as an umbrella organisation for taking care of forestry research, education and extension needs of the country. Finally on 1st June 1991, the ICFRE was declared an autonomous Council under the then Ministry of Environment and Forests and registered as a Society under the Societies Registration Act, 1860. Council has a sharp vision to achieve long-term ecological stability, sustainable development and economic security through conservation and scientific management of forest ecosystems.

Q: How do you evaluate the Importance of forests for supplying raw materials to various industries? Like Pulp and Paper Industry.

Definitely various industries like plywood, and composite wood and even pulp and paper are big consumer of green resources but the sustainability of forest resources can not be looked only for industrial production but attention should also be paid for other direct and indirect services as well. In fact, enhanced share, of recycle and agro based material in pulp and paper industry is appreciable, which definitely could lead in conservation of forest and environment. In addition, a significant increase in the productivity of forest resources on a sustainable basis and large-scale extension of industrially linked agro-forestry system may play a crucial role for satisfying the industrial raw material requirements.

Q: Recently in the Union Budget, the government’s support to boost agroforestry in the country by Availability of additional 25 lakh hectares for agro forestry will ensure raw material security for wood-based industries. Please shed some light on this policy initiative and its framework.

The government’s support to boost agroforestry across the nation is highly appreciable. The initiative will not only assist to provide enough raw materials for all wood-based sectors at rates that are competitive with the rest of the world, but it will also help to increase the country's tree cover, employment generation, supplement farmer incomes and benefit the environment in a variety of other ways. It may enable all wood-based industries to meet out the supply-demand imbalance in the near future through the sustainable supply of raw materials within the legislative and policy framework of the forest act.

Q: According to Indian Paper Manufacturers Association (IPMA), Over the last several years, the Paper industry has worked tirelessly with over 5 lakh marginal farmers to successfully plant 12 lakh hectares of largely degraded land. However, despite the paper industry's efforts to promote plantations, domestic wood availability remains inadequate. How does ICFRE see the paper industry dilemma for wood availability?

This plantation initiative of Indian paper industry deserves to be appreciated. But we also have to see here whether the paper industry is either only helping or encouraging the farmers in the plantation or also going in any kind of MoUs or agreement with the farmers for sustainable supply chain. The matter of concern is whether the paper industry is paying the same to the farmer for wood as is being paid by industries like plywood etc.? Certainly the plywood industry is the major consumer of wood produced from farm forestry, but the paper industry will also have to find ways to encourage the farmer for regular supply by keeping a competitive price in the market.

Q: Some International Forest managed by big paper mills are taking part in an initiative to automate the production of improved seedlings, Automated in vitro Somatic Embryogenesis (SE) technology for large-scale production of elite plant material. Somatic embryogenesis (SE) is a method of vegetative propagation, where from a single seed one can produce large numbers of plants. Do you think this technology can improve social forestry in India, how do you evaluate this technology and its impact, please describe?

Quality planting stock is the first and foremost necessity of any plantation activity. Biotechnological tools like tissue culture, somatic embryogenesis etc. now have established protocols for important tree species. To achieve the plantation targets in social forestry multiplication of genetically improved plant material is possible with the help of these techniques only. As on date fast growing and high yielding planting stocks are available in desired quantity only because of these biotechnological tools. Further, development in modern tools for tree propagation, improvement, and breeding can mitigate enormous pressure on trees due to the rapid increase in human population size, environmental pollution, and demand for timber products. In vitro propagation could be the key of mass clonal propagation of desirable genotypes, with the provision of suitable target material for genetic transformation.

Q: What should one understand the term ‘wood consumed from responsible forests’?

We can understand the responsible forest as a system of management in which health and diversity preservation of the forest is aimed with the fulfillment of societal demand of forest products. Clear cutting prohibition, value the rights of forest peoples, biodiversity conservation are the key features of responsible forest along with regular productivity and regeneration capacity. I think the forest based industries, those are dependent on or even consumed certified raw material from responsibly managed forests are contributing towards the sustainable forest management goal of the country.

Q: There has been a myth spread about ‘Paper’ that it is being manufactured by cutting down trees, it is harmful to the environment, Do you think that our national forestry policy and law will allow paper mill to cut down a single tree illegally from the forest managed by governments? Please clear the myth about cutting down trees.

Utilization of forest based resources without any restrictions and limitations may create numerous ecological imbalances. Although, deforestation causes many harmful impacts on environment but the sincere efforts in the development and maintenance of parallel forest eco-system through afforestation programmes may assist in the maintenance of ecological imbalances. Additionally, the dependence of paper manufacturing on forests gets minimized to a certain level as of today, when Indian paper sector shares major production of paper from recycle grade paper together with agro-residues. Even industry’s approach towards more and more utilization of recyle grade fiber can be seen as a step towards environmental protection. This is true that some class of paper requires virgin wood pulp for which wood availability should be ensured by farm forestry and responsible forest in procedural manners.

Q: Being a research institute please shed some light on the research of new species or plantations for the paper industry being carried out by ICFRE.

In the recent past under different tree improvement research programmes ICFRE has identified and developed various fast growing high yielding clones/plus trees of different species. Plantation of such high yield varieties under different agro-forestry scheme may facilitate Indian paper industry to get sustainable supply of quality raw material for production of pulp and paper. Paper industries by their ownself and by promoting farmers may grow those high yield varieties for sustainable supply of raw material.

Q: To mitigate the wood import for various industries in India, the Industry needs high-yielding clones to get higher yields in a shorter time. How ICFRE is working on higher yields clones, also farmers need technological support for effective farm forestry, please shed light on better knowledge transfer to farmers?

Under different tree improvement research programmes ICFRE has identified and developed high yielding clones/plus trees of Melia, Eucalypts, Bamboo, Casuarina and poplar. Multiplication and need based distribution to stakeholders of these genetically improved planting materials is one of the prime extension strategies of ICFRE. ICFRE approaches to the farmers through Van Vigyan Kendras (VVKs), Demo villages, Tree growers mela and other outreach programme through print and electronic media. ICFRE established the VVKs with the objective of dissemination technologies to the user groups where as Demo Village have been established for demonstration of technologies developed by ICFRE for sensitizing the stakeholders. Tree Growers Mela has become a regular feature in all institutes of ICFRE.

Q: The number of FSC certification has increased manifold in recent years, some big paper mills in India has FSC certification. But, India now holds a globally recognized certification scheme specifically developed for the Indian forests. The Network for Certification and Conservation of Forests (NCCF), a not-for-profit organization, has been successful in obtaining the endorsement of its forest certification scheme from the Programme for the Endorsement of Forest Certification (PEFC). Will this local certification of India Forest provide international recognition to Indian companies?

Rich biodiversity and forest variability along with scientific and traditional forest management practices makes our country different from rest of the world. A flexible and forest type based certification system is the necessity to be adopted. These tools support directly or indirectly the social benefits, economic existence and protected environment with a vision of sustainable forest management. We have to remember here that the genesis of a certification system, with the adoption of all the measures of standard setting organizations followed by global best practices, makes it more credible.

With the adoption of programme, it may assume that companies definitely will get global recognition due to enhanced creditability and better market accessibility of forest products.

Further we have to be hopeful and look forward because of the involvement of PEFC and National Board for Accreditation of Certification Bodies (NABCB), as a member of, International Accreditation Forum (IAF).

Q: Any other research or comment you want to share with our paper industry readers?

In the recent past, the development in the Indian pulp and paper industry could be largely attributed to the pioneering contributions made by Forest Research Institute (FRI), Dehradun through researches on various aspects of utilization of different raw materials for the production of various varieties of paper and board, on one hand, and pulp wood production forestry on other hand. Laboratory experiments conducted in the FRI were translated into pilot plant trials for commercial success. At present, the growing consciousness about environment protection has forced industries to adopt the cleaner production technologies. In view of this, we not only have to look for the industrial production activities but sincere efforts should also be done to conserve the natural resource as well.

Web Title: ICFRE Dependence of paper manufacturing on forests gets minimized to a certain level as of today

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)