China's Downtime And Plastic Ban are Enticing 40 To 45 New Paper Mills Every Year In India

China's Downtime And Plastic Ban are Enticing 40 To 45 New Paper Mills Every Year In India

Ghaziabad | 17 Nov 2018 | The Pulp and Paper Times

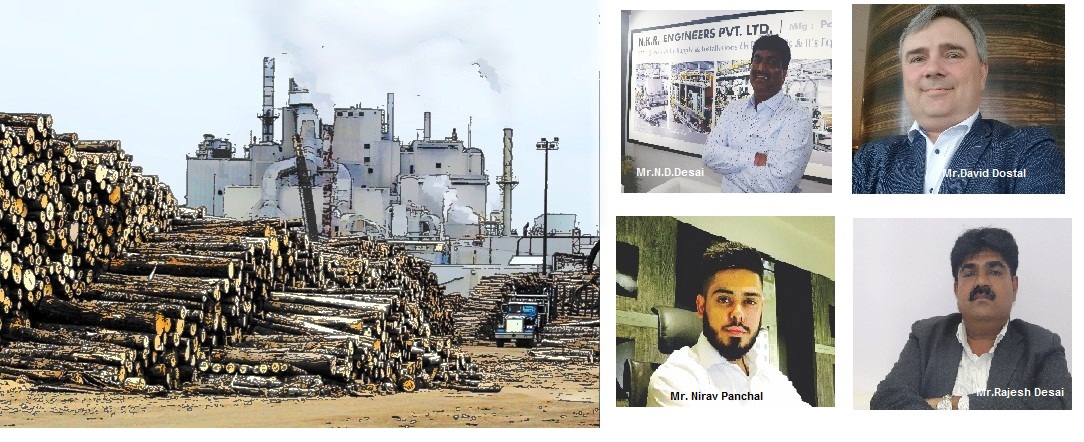

The capacity shutdown in China due to the ban of waste paper import is making paper manufacturing business India's 5th largest sector for Investment. The Paper machine market in India is growing 10 to 12 % year on year basis. “The demand of Kraft and other paper from China and Southeast Asian countries are continued to grow every year which makes investment in paper sector a lucrative offer. The internal demand of paper and China's factor are inviting 40 to 45 new paper mill establishments in a year. The average size of capacity for a new paper mill is 200 to 300 TPD.†informed by Mr. N.D. Desai, Managing Director of N.K.R Engineers Pvt. Ltd., a paper mill Machinery manufacturer from Gujarat.

“India is the fastest growing paper market globally, growing at over 7 per cent and projected to grow at over 4 per cent per annum till 2030 to 27 million tonnes by 2030. The industry has made an investment of over Rs 20,000 crore in last 5 years and it needs investments of Rs 90,000 crore to add new capacities by 2030,†JK Paper Vice Chairman and Managing Director Harsh Pati Singhania told in a conference on paper industry two years back. This investment figure signals combined opportunities for Instrument, Equipment, Waste paper and Chemical Suppliers.

“Productivity and Profitability are the major concern for any paper mill in India and we are very much concern to these two factors. Productivity is mainly given by the width and Speed of the machine. Papcel after the acquisition of PMT, ICONe and ABK group, is able to propose most modern machine with a maximum width and speed. But of course, up to now there is no demand for such a size of the machine in India. There is much more demand in China for example. Of course, a trend is changing here in India, the new projects which are planned and announced, are bigger than once which were done before. Indian Paper Industry is going towards improvement in productivity and efficiency.â€

“The most important is 'cost of the Capital'. In India, Cost of the capital is too high if the interest rate is less than the process of improvement of productivity would go much faster. Today, the growth of owners is very limited due to expensive 'funds'. What I also feel that, Owner of paper mills also afraid to source the good from abroad due to high exchange rate risk.†explained by Mr. David Dostal, Chairman of Board Papcel during an interview to The Pulp and Paper Times.

“Even if China's factor doesn't work in coming years, local demand of paper itself is capable to sustain the paper industry. We are supplying 7 to 8 new paper mill machine setup in the different part of the country and overseas market this year witnessing the average growth of 20% in our business. Quality Kraft paper demand has become first priority for converting industry and we heed towards the productivity of quality paper. Apart to the new mills, most of the existing paper mills are also exercising the expansion plan to meet the demand.†said by Mr. Rajesh Desai, Managing Director of D.S. Engineers, a paper plant manufacturer.

“Paper is a product which touches everybody’s life. The Government's support and other driving factors to the market; making the paper industry sustainable. We deal in 'Stock preparation' machinery and in last two years, we have completed the installation of this machinery in around 200 companies including overseas numbers. The trend has been changing since last few years; customers from Bangladesh, Dubai and Egypt's paper mills are giving priority to Indian paper machinery as compared to the European and Chinese counterparts.†Mr. Nirav Panchal, MD of Ambica Paper Machineries said.

“The implementation of plastic ban in various states of India, shifting the people’s habit from plastic to paper carry bag. Million tonnes of plastic could only be replaced by new paper mills and we are doing work on 8 new paper mills simultaneously this year.†Mr. N.D. Desai said.

“There is still a gap of various products that are not being manufactured in India like CI dryer, Suction Rolls and presses. We need to purchase these products from China as demanded by customers. As regard to European Machine, definitely, they are superior to us in terms of work accuracies and speed of the machine. We can't go behind 450 m/min but they can go up to 1000 m/m.†Mr. Rajesh Desai explained.

Web Title: China s Downtime And Plastic Ban are Enticing 40 To 45 New Paper Mills Every Year In India

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)