A new paper mill in Gujarat, aims to step into high BF and lighter GSM Kraft Paper manufacturing

A new paper mill in Gujarat aims to step into high BF and lighter GSM kraft Paper manufacturing

Surat | 3rd October 2021 | The Pulp and Paper Times:

Kraft papers have a rising trend of manufacturing it through natural recycling which has though lesser strength than virgin natural craft paper, but it is more eco-friendly and still has enough strength to fill void applications. The growing packaging industry and paper industry is largely driving the growth of the global kraft paper market.

“The evolution of the packaging industry across the globe acts as one of the major factors driving the growth of kraft paper market. The increase in demand for sustainable and recyclable material from packaging and various other end-use industries, and advancements in packaging and wrapping applications accelerate the market growth. The rise in demand for more environment-friendly and effective packaging materials and solutions from end-use industries such as foods & beverage, pharmaceuticals, cosmetics & personal care, and electronics, and rise in consciousness regarding environment among population further influence the market,†Said Mr. Milan Vidaja, Managing Director of Shree Varudi Paper Mill LLP.

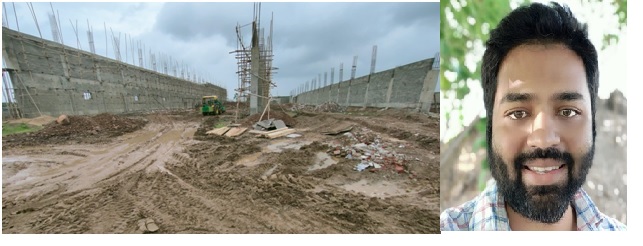

Situated at Mangrol, Surat (Gujarat), Shree Varudi Paper is investing to tap the higher BF and lighter GSM kraft paper segment. “Yes, we are setting up a new kraft paper mill with 200 TPD paper production capacity targeting a quality paper supply for a paper bag and corrugated box manufacturing in the region. We are aiming to manufacture paper from 60 to 200 GSM while BF range will be 16 to 45†Mr. Vidaja said.

“We are expected to invest around INR 50 crore in this new paper mill, now the building construction work is in full swing and machinery erection work is expected to start in couple of months and we are scheduled to commence the production in the second half of 2022†Mr. Vidaja informed.

The single wire machine has 4.15 meters finished deckle. “We had placed order to Micro Fab Industries for supplying the entire plant and machinery expect pulp mill section which is being supplied by Parason Machinery,†He said.

Parason machinery is supplying the stock prep with the latest technology equipment for pulping cleaning screening. The paper mill has included fine cleaning systems also to avoid spots in paper.

The new paper mill is setting up a state-of-art infrastructure in order to reel out quality paper for packaging purpose.

About Paper machine:

1) Headbox:- Air-cushion headbox with complete PLC based (auto controlling of jet to wire ratio), have the facility to maintain L/B ratio.

2) Wire part :- sicer ceramics tops , suction couch and dandy roll is been installed making it both quality and quantity viable, also lumpbreaker is added to suction couch

3) Press section: - It has a k type suction press for better run ability at lighter gsm fluting paper / jumbo press as a second press.

4) Dryer section:- Cast iron dryer cylinder 1.8 m diameter with rope groove and from pre dryer first cylinder to pope reel is auto feeded , All guiding is from E+L and Stretchers are mechanical and motorized for all felt, dryer screen sections.

5) Size press:- hydraulic loaded for even impression and sizing penetration 1000 mm in Dia makes better for lighter gsm fluting, avoids splashing at high speed.

6) Pope reel:- reel Dia capacity of 2000 mm and it hydraulically / pneumatic loaded with IBS basked reel turn up considering safety operation at pope.

The Paper mill is also eyeing the export of paper, “we are planning to export around 30 to 40 percent of our production to overseas destinations†Mr. Milan concluded.

Web Title: A new paper mill in Gujarat aims to step into high BF and lighter GSM Kraft Paper manufacturing

More News From india

Next Stories

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)