Saloni PMPL: Executing Paper Mill projects from layout to Installation with automatic features

Saloni PMPL: Executing Paper Mill projects from layout to Installation with automatic features

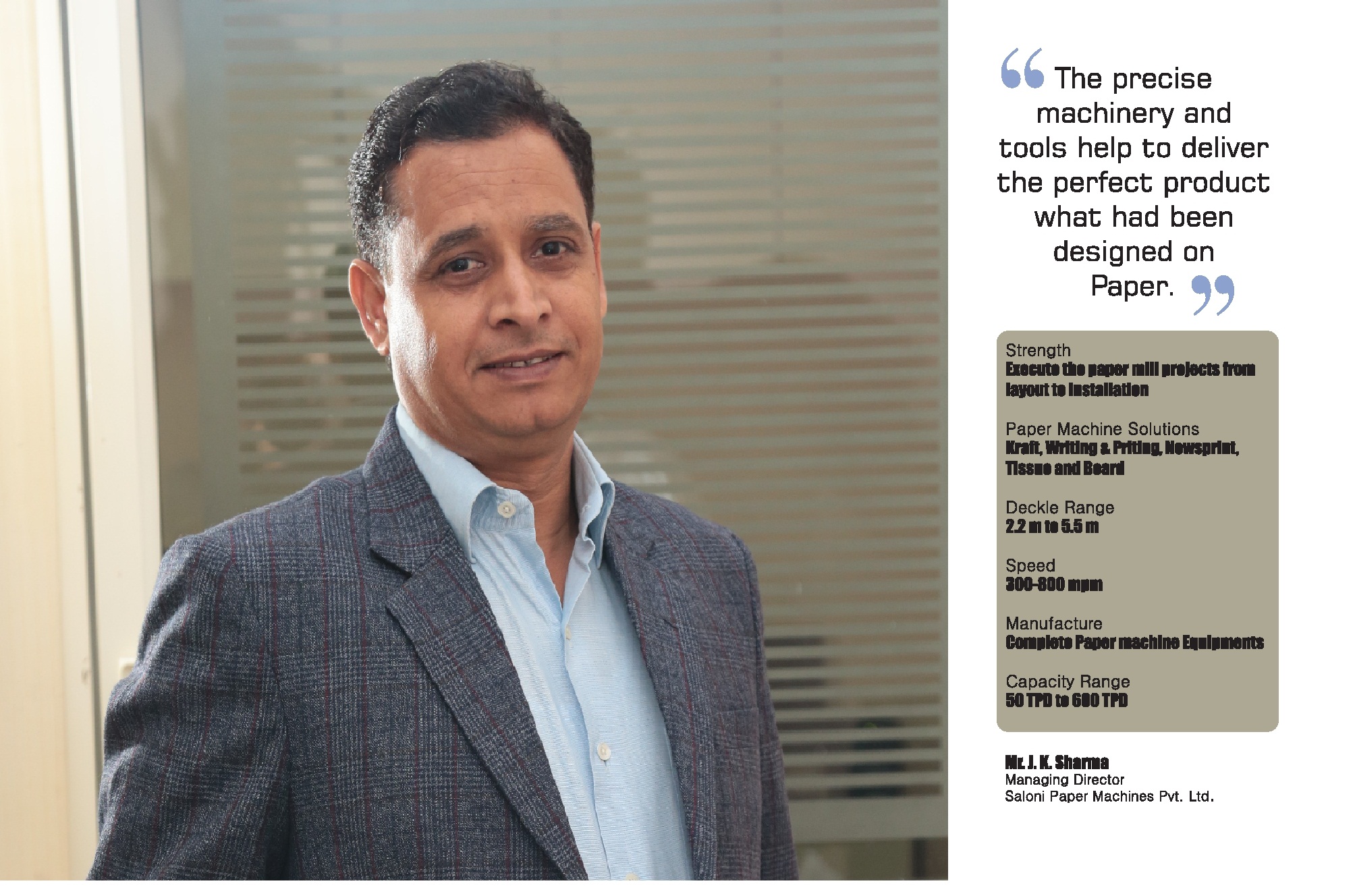

An exclusive interview of Mr.J.K.Sharma, Managing Director of Saloni Paper Machines Pvt. Ltd. - a well recognized manufacturer of Paper Machines. Know the insights of their operations and successful delivery.

Q. Could you tell us a bit about Saloni Paper Machines and its product portfolio?

To start with, we became a part of the paper industry in 2004 as erectors, continuing to do so we then entered the manufacturing sector of paper machines in 2010. Saloni PMPL strives to serve customers the best quality products with efficient service. We provide tailor-made solutions to the customers accommodating all their requirements. We cater to all sectors of the paper industry which include Kraft paper, Writing & Printing, Newsprint, board, and tissue. We implement projects starting from the planning to the commissioning of the paper machines. We manufacture complete Paper machine equipment which includes fourdrinier section, Straight press, Bi-Nip Press section, Bi-Nip (K-type) with Jumbo press, Dryer section, Size press, Calendar, Pope reel section, Rewinder and many more. We have worked with a wide range of paper deckle from 2.2m to 5.5m with an operating speed of 300-800 mpm. Saloni PMPL is one step destination to execute the project from layout to installation & commissioning of the high-performance paper machine with automatic features.

Q. What challenges did you face which you have converted into your success?

I think the expectations of the customers have increased since years from providing only equipment to complete Project engineering which has also become a need of the hour. But instead of considering this as a challenge we have converted this into an opportunity and have build up our team and developed all the skills to provide complete engineering and support starting from the planning to the commissioning of the project to ensure smooth start-up & hassle-free operations.

A number of new and rebuild projects have been successfully commissioned along with automation on SALONI PMPL's project engineering support and guidelines.

Q. How do you analyze the transformation of the India Paper Industry in the last 10 years and what transformation in paper mill operation do you see in the next ten years?

According to our experience, there has been an appreciable growth in the demand of Kraft and Board paper as good packaging and presentation has become an important factor in today's market. Not to forget that the other sectors of Writing Printing and Newsprint still pertain their importance but there has been a lot of development in the design and engineering of Kraft & Board paper machines over these 10 years.

Developed All the skills to provide complete engineering and support starting from planning to commissioning of the projects to ensure smooth start-up & hassle-free Operations.

A number of updated technologies have become common in the market like the Multi-wires concept, Top former in the wet section along with Wide nip concept for ensuring higher off press dryness without sacrificing much of bulk of the sheet which is a most important board property. Also, operational energy conservation has become one of the main topics of discussion and an important element to be considered in the designing of machines in every project. If we talk about the transformation in paper mill operation for the coming years would be related to automation because the integrated Pulp and paper mill sizes are increasing day by day, With the increasing operating speed and capacity, it will become difficult to have manual control operation in number of stages. So gradually, more and more automation will be seen in the paper industry. Also, with the exhausting natural resources, operational efficiencies for pollution control and effluent management will become a crucial part of the projects rather than a value-added feature.

Q. What obstacles do you see in paper mill operation which stop a paper mill to grow with better margins?

As I already mentioned, Pollution control and effluent management is very important for any paper mill. With the reduction in the availability of water and increasing pollution, we have to focus more on zero discharge effluent treatment plants to produce odorless paper and save the environment. This calls for the installation of required equipment for water treatment and infrastructure to minimize pollution which adds up to the production cost and reduced margins. Hence, we as a team need to work on more efficient operational processes and incorporate such features in the designing of the machines to achieve the same. Another important factor is the dependency of the Indian paper industry on basic raw material from foreign resources. Around 65-75% of paper in India at present is produced from recycled fibres, the major source of which is foreign supply. Variation in the price of this raw material sometimes causes appreciable concern regarding the economic viability of the mill. This may become a major concern to the paper mills unless a continuous and steady supply of basic raw materials at a reasonably stable price is ensured. We need to work on proper Indian waste paper collection channels so that the dependency on foreign resources can be reduced.

Q. What are the new trends in paper machine designing? How these trends are effective in mill operation?

In order to stand out in the competitive market, Paper mills are aiming to increase the production and improve the quality of product which in turn demands for high speed machines and modern technologies. So, according to us some of the trends in machine designing are selection of hydraulic headbox with dilution control for better formation and more uniform profile, Top Former for limited wire length, closed draw concept from wire to press section particularly for Paper Machine with lower basis weight and higher Machine speed in case of both Writing& Printing /kraft paper, Bi-nip, Tri-nippress section and shoe press to improve the paper property, switching from gear drive to silent drive in dryer section, unirun concept has become common in Newsprint, Kraft, Board,Writing& Printing, effective hood and PV system for dryer section to ensure higher evaporation rate, spool loading arrangement for pope reel and ropeless tail feeding system with the increasing operating speed.

In talk with some organizations for the development of Shoe press and Film sizers.

Q. Does technology play an important role in successful delivery? Are you open to any kind of Joint venture for the development of better engineering delivery?

Yes, I agree that technology plays an important role in the manufacturing of any engineering product. The precise machinery and tools help to deliver the perfect product that had been designed on paper. However, along with technology, engineering design of the product based on necessary knowledge regarding the application and functioning of the equipment is also very important. SALONI PMPL with the required infrastructure equipped with a number of VMC & CNC machinery and operational knowledge has successfully completed various projects to the best satisfaction of the customers.

As far as Joint Ventures are concerned, continuous growth for us and our customers has always been our mantra, so yes, we are open to any opportunity that comes up and helps to develop new products for the industry. In fact, we are already in talks with some organizations for the development of shoe press and film sizers.

Q. What is the role of digitization in paper mill operation? Where does Indian Paper Industry stand in this digital era?

Digitization has become very common in different industries to have a proper idea of ongoing process operation. The information what we get helps us to monitor and control the operations more efficiently. In India also, many paper mills have already started to adopt it to analyse and monitor the situation and act accordingly.

Q. How do you execute the training and support post-sale of your delivery to the paper mill?

We actually do not believe in pre-sales and post-sales phase, once we get connected to the customer it becomes our duty to serve them whenever they need which could be a product requirement, service or just a suggestion, we are always just a call away. We execute the complete project as partners and not as some outside vendor because as it is rightly said, coming together is a beginning and working together is a success.

Thanks

Web Title: Saloni PMPL Executing Paper Mill projects from layout to Installation with automatic features

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)