The acquisitions of RunEco Vacuum Systems by Silverton and Satia Industries signify the growing importance of the Indian market in Runtech's global strategy

The acquisitions of RunEco Vacuum Systems by Silverton and Satia Industries signify the growing importance of the Indian market in Runtech's global strategy

- Local Expertise and Energy-Efficient Solutions: Runtech Systems Expands Presence in India

The Pulp and Paper Times

Runtech Systems is advancing its commitment to the Indian market. Strategic enhancements in dewatering and vacuum systems are pivotal for bolstering energy efficiency, minimizing environmental impact, and upholding high production standards. With a fleet of 14 Runtech EP Turbo Blowers operational in India and more on the horizon, the drive towards more efficient and sustainable production is clear. Recent acquisitions of RunEco Vacuum Systems by Silverton Pulp & Paper Pvt. Ltd. and Satia Industries Ltd. signify the growing importance of the Indian market to Runtech's global strategy.

To cater to market demands, Runtech has assembled a skilled team to deliver in-depth support and service to our customers, aiding the paper industry's quest to cut energy use and carbon emissions. The newly onboarded team comprises Bharat Kumawat as Application Engineer, Ankur Dwivedi as Sales Manager, and Ankit Gupta as Field Service and Project Engineer. Our enduring partnership with Eintec remains integral to bolstering our business and extending our reach within this key region.

SILVERTON – Pulp & Papers Pct Ltd. to Extend Production Capacity

The delivery to Silverton Pulp & Paper Pvt Ltd. PM5, in Uttar Pradesh, includes three EP600 Turbo Blowers with EcoDrop Water Separators. In addition, EcoFlow Dewatering Measurement Systems will be delivered to PM4 and PM5. The new PM5, relocated at the Muzaffarnagar site, will produce 430 tons/day of writing & printing grades, with a start-up scheduled for 2025. The existing PM4 has operated using EP Turbo Blowers since 2019.

“We have worked together with the customer for a long time, and they have good experiences with our energy-efficient technology. We are delighted to continue the good cooperation with Silverton. Replacing the liquid ring pumps at PM4 resulted in energy savings of more than 50%. With EP Turbo Blowers, PM5 will benefit from this adjustable, water-free technology right from the start”, says Tommi Leander, Sales Manager, Runtech Systems.

Silverton Pulp & Papers Pvt Ltd. is a rapidly growing enterprise of Paper Industries Group. The Group holds a diversified portfolio in manufacturing a high standard of products including printing & writing paper, as well as packaging grades. The Group also supplies high grade quality craft papers. Silverton currently operates four paper machines with an annual production of over 227,000 FMT.

SATIA – Trusted Partnership to Improve Efficiency and Runnability

Operating four paper machines in Muktsar, Punjab in India, Satia has an annual capacity exceeding 220,000 tons of printing and writing papers using agricultural residue such as wheat straw, sarkanda, wood chips, and waste paper as raw material.

“We have worked together with Satia Industries to improve the efficiency of the processes and unlock the potential their machines have. One great way to discover possible bottlenecks and improvement potential are surveys. Firstly, it provides a clear picture of the current state of the system, highlighting any inefficiencies or malfunctions that may have gone unnoticed. This preemptive approach can prevent more significant issues from arising, saving both time and resources. Secondly, the survey can reveal opportunities for reducing operational costs or improving operator safety”, says Tommi Leander.

Last year, Runtech Systems received vacuum system rebuild orders for Satia’s PM1 and PM2. Delivery included two RunEco EP600 Turbo Blowers with EcoDrop water separators, replacing existing liquid ring pumps. RunEco vacuum system on PM4 started up at the end of 2021 and PM3 in early summer 2022. This year, Satia has also contracted Runtech to upgrade the tail threading to ropeless on PM3.

“We are delighted to replace 25 years old water ring vacuum pumps with new Runtech-supplied vacuum blowers. We are saving a good level of energy by installing these blowers while keeping the desired vacuum levels and the results are satisfactory. We commissioned a new Allimand paper machine with a speed of 1100 mpm with these efficient Runtech Vacuum Blowers in February 2022. We are getting the required results of the vacuum levels with lower power consumption compared to LRPs.

Looking into the results of the above blowers, we placed the order for two more vacuum blowers to replace our 30-year-old water ring vacuum pumps on our two machines, PM1 and PM2. We are very pleased with the performance of these blowers”, commented Hardev Singh, Director (Technical), Satia Industries Ltd.

“The main reasons why RunEco systems were found most suitable for Satia’s machines were flexibility in process, superior energy efficiency, adaptability to existing piping and building as well as Runtech support in design, installation and startup. The existing turbo blowers on two paper machines have fulfilled the expectations since start up so Satia had a good idea what they were going to get, and we are very happy with the trust they place in us”, Tommi continues.

Meet the New Local Runtech Team

With a strong background in the Pulp and Paper Industry as a paper machine clothing specialist, Bharat Kumawat is based out of our Pune office as an Application Engineer. Bharat’s main responsibilities are paper machine surveys in India.

“We perform comprehensive on-site paper machine audits, such as vacuum section audit, forming section audit, press section audit, dryer section audit, moisture profile audit, machine hall ventilation audit, tail threading audit & paper machine runnability and efficiency audit in India that enable the identification of production and runnability problems in the paper machine. We will give you valuable information and recommendations how to improve your process and machine runnability and reduce energy consumption. An extensive analysis of the papermaking process factors from the wet end to the reel = massive overall energy savings for the mill.

Runtech audits and troubleshooting are always tailor-made for the specific customer needs. Strong specialization in the field, profound know-how and wide experience enables our customers to save both money and time.

After the audit and comprehensive discussions with the customer, we provide a complete written report summarizing necessary actions for production optimization”, says Bharat Kumawat.

Ankur Dwivedi, a Sales Manager based in Delhi, will be responsible for handling existing installations and developing the Paper & Pulp Industries market in India for Runtech. Ankur has extensive knowledge of paper industry from both supplier and customer perspectives.

“Having an indigenous technical and sales team in India would significantly enhance our ability to serve Indian customers more efficiently and rapidly. Let’s join hands to make our planet more prosperous and greener. Runtech Systems’ advanced technology helps in reducing the power consumption ~ 45%, which translates to energy savings of 2.6 TWh and a reduction of 769,000 tons of CO2 a year with the current installed base.

Runtech's patented solutions include energy efficient vacuum system and heat recovery optimization, runnability optimization, dewatering, doctoring and cleanliness optimization as well as ropeless tail threading for tissue, board, paper and pulp machines.

Runtech Systems already has many happy customers with a good installed base of EP Turbo Blowers, and a few more customers will be added to this list very soon.

We value your business and are always looking for ways to serve you better by offering our wide range of products and services for the paper mills”, says Ankur Dwivedi.

Ankit Gupta, Field Service and Project Engineer, will be responsible for turbo blower services and supporting new system installations and start-ups. He has extensive experience in and knowledge of the paper industry.

“With the state-of-the-art advanced technology and tailormade systems, Runtech Systems works with the customer by reducing the energy consumption and carbon footprints to maximize the efficiency and cost effectiveness.

Runtech System has a comprehensive product portfolio. We are happy to serve our customers with the best solutions to maximize their productivity and machine runnability which results in more profitability and less energy”, Ankit says.

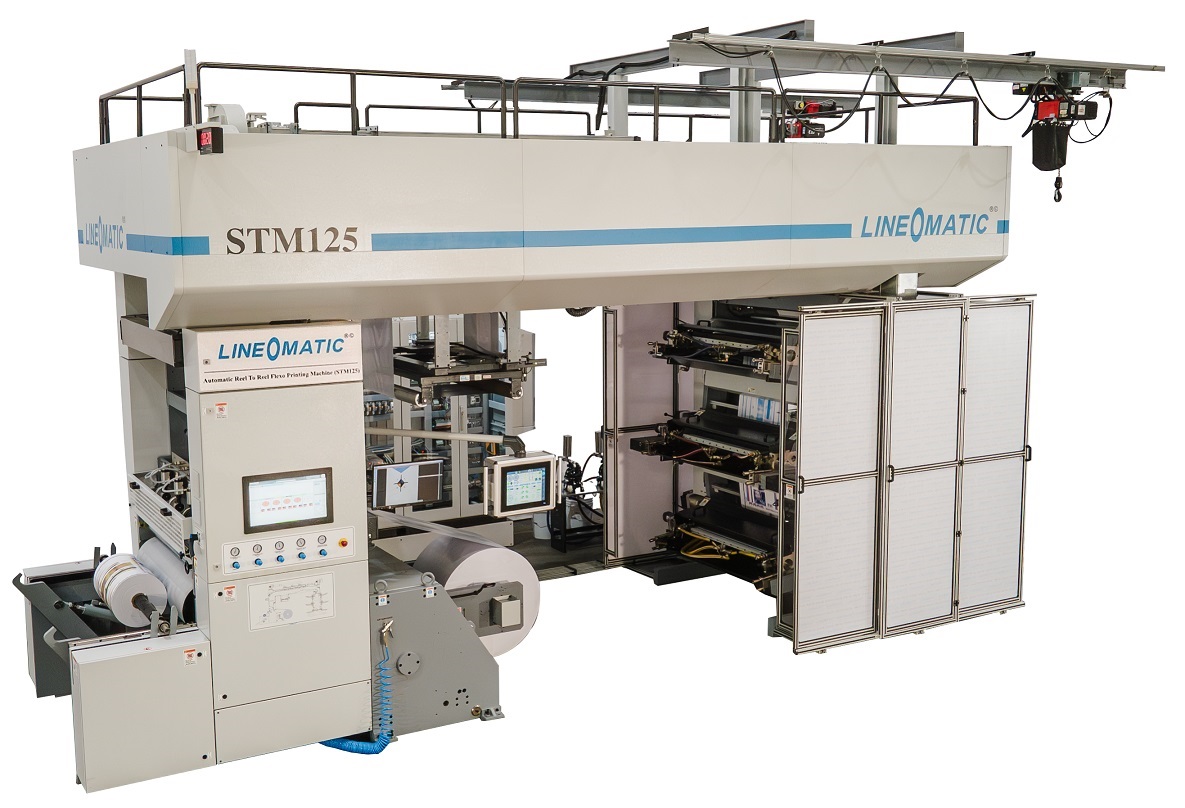

About EP Turbo Blower Technology

EP Turbo Blower technology marks a significant leap forward in energy efficiency for the industry. This technology has consistently delivered energy savings between 40% and 70% in various rebuilds, compared to conventional vacuum systems. These savings stem from the innovative turbo technology and the precision with which water removal can be measured and vacuum levels can be fine-tuned to their most effective points.

Designed for flexibility, EP Turbo Blowers maintain efficiency across diverse vacuum levels and airflow rates. This enables paper mills to adjust vacuum levels for optimal performance without compromising on energy savings. The high-speed motors in these blowers, coupled with frequency converters, supply vacuum levels that can vary from 30 to 70 kPa, accommodating a broad spectrum of operational demands.

The water-free operation of EP Turbo Blowers significantly cuts down on water and chemical usage within vacuum systems. Additionally, this feature negates the need for ancillary water-management equipment, such as cooling towers and circulating pumps, leading to further reductions in operational costs and environmental impact.

Web Title: The acquisitions of RunEco Vacuum Systems by Silverton and Satia Industries signify the growing importance of the Indian market in Runtech's global strategy

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)