“I do not see China being a long-term market for Indian Paper mills, ASEAN countries are having surplus capacities in paper making, with no potential for export” : M L Agarwal

“I do not see China being a long-term market for Indian Paper mills, ASEAN countries are having surplus capacities in paper making, with no potential for export” : M L Agarwal

-Over times the demand & supplies matched in China, and I do not see China being a long-term market for Indian mills

- Molded Tableware & Restaurant takeaway supplies as major market mover

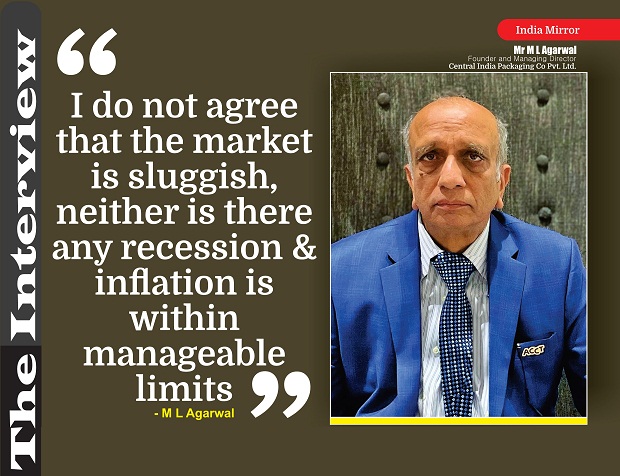

Recently, The Pulp and Paper Times spoke to Mr M L Agarwal, Founder and Managing Director, Central India Packaging Co Pvt. Ltd, and Vice Chairman of International Corrugated Case Association (ICCA). Mr Agarwal, having headed Federation of Corrugated Box Manufacturers Assocition (FCBM) way back in 1989 and then having been instrumental in formation of Asia Corrugated Case Association (ACCA) in mid 90s & then heading that august body in 2003-5.

In 1970 Mr Agarwal took over the small Card Boardmaking factory of the family. In the year 1979, he diversified into allied line of packaging for the manufacture of Corrugated Boxes, Printed wrappers, and Laminated Film etc.

Mr Agarwal discussed the packaging and corrugated market scenario, sluggish demand for paper manufacturers, export prospects for Indian Kraft Paper mills and global development in packaging. Here are his full views:

Q: Please give us a brief introduction of Central India Packaging Co Pvt Ltd (CIPCO)?

Central India Packaging (CIPCO) was started by M L Agarwal, in 1980. Very soon it became a brand to recon with most leading corporates in its client list. CIPCO pioneers technological development in corrugation industry making a move from material specifications to performance-based way back in 1985.Quality & service are cornerstones for the success of CIPCO,

Other companies in group are Central India printing Co which was the leading supplier of wax costed wrappers for biscuits & breads pan India. With advent of flexible packaging expansion into sunrise was a natural corollary, achieved with setting up of Ankit Packaging Ltd.

Q: Being a reputed packaging solution provider and Corrugator for last four decades, what is your quick review of the present corrugation and packaging market scenario? Paper prices have come down to all-time low.

Packaging Markets do not move in any fixed direction, these at most are cyclical ups & downs. But Corrugated being a vital transportation packaging does not have major swings but moves with the growth of market at large. Best example, during Covid many areas of business suffered, but Corrugated Packaging and Packaging Paper did not suffer much as the consumption of daily needs is always present hence need for Corrugated Packaging is ever green. Highs and lows are relative and use of term ALL time is not correct as current prices, though about 15% below the peak, are 7 times the price of my first purchase of paper 40 years ago. Kraft paper prices to some extent follow the movement in prices of major input, i.e., Wastepaper.

While sale of packaging is demand driven and based on contractual obligations between buyer & seller, Paper is more of a commodity, susceptible to market vagaries, both national & international.

Also, prices are relative to movement of prices of Raw material. The fall in prices of paper is almost equal to the fall in prices of Recovered paper, hence profitability of paper manufacturers is almost intact. Such factors are common in business and do not affect the medium-term prospects.

Q: How do you see the demand perspective of corrugated boxes in the sluggish market? Do you think organic growth of packaging from the market has vanished due to recession or inflation & high-interest rate?

I do not agree market is sluggish, neither is there any recession & inflation is within manageable limits. Corrugated packaging has been growing handsomely year on year and currently growth rate is 10%+ per annum and rate of growth will be almost constant in near future. Packaging demand is driven by consumer spending. With rising incomes, increase in consumerism, increase in consumer preference for ready to use products of daily needs, and general consumer preference for better presentation will only see a healthy rise in demand for packaging and also for upgrading presentation of packaged products. All these are good omens for growth of Corrugated Packaging.

Q: Any product’s impact comes not just from the product itself but also from how it’s packaged and delivered to the customer. How do you evaluate the perception of new-age consumers about compostable and sustainable packaging? Does the packaging keep an ‘edge’ on the Products?

Much of this has been answered in Q3. Corrugated Packaging is perhaps most sustainable packaging with almost 90% recycled into new paper. Very little finds its way to land fill. Yes, within corrugated there is trend for downsizing/ lightweighting which can & will see some impact on tonnage but not much on value due to upgrading of box presentation, graphics etc. Technical innovations will protect the contribution to box manufacturers.

Q: Excess Capacity and Export decline have hit hard to Kraft and Duplex paper mills across India. They operate at lower capacities or take shutdown. What factor do you forecast behind this scenario?

Exports of Container Board/ Corrugation paper from India are of a very recent phenomenon. India did not figure on the global Container Board/ Kraft paper market due mainly to; 1. Quality issues; 2. Very low capacities of Mills not conducive for fulfilling export demands.

Exports to China were more emergency purchases to meet sudden shortfall in container board production in China to; 1. Crackdown by Govt on Pollution issues; 2 Closing of several non-viable small mills and 3. most important stoppage of imports of wastepaper by Govt. Also, at same time all commodities went through as step upswing globally. This presented a golden opportunity for Indian mills to divert surplus capacity for exports. Over times the demand & supplies matched in China, and I do not see China being a long-term market for Indian mills.

Likewise, ASEAN countries were never a market which themselves are having surplus capacities in paper making &they make better quality paper. There is no potential for Indian Mills in ASEAN.

Yes, Indian sub-continent & Middle East are a market for Indian mills, but the quantity involved is insignificant. 3-4 years of boom in paper market globally have led to huge increases in capacities by many existing mills and many new mills on the market creating a mismatch in demand supply. There is no shortfall in supply in any market. Only USP Indian mills have is Lower cost of operations which to some extent compensates for the lower quality of Indian paper, which can be exploited in some markets.

Q: how does Central India Packaging absorb Environmental, Social & Governance (ESG) in the Packaging, Why is it becoming more demanding nowadays?

As already mentioned, Corrugated is one of the most Eco-friendly packaging, using minimal natural resources and hence there are no environmental concerns. Due to the very same reason it one of the most accepted packaging by society. Governance is something industry has learnt to live with & With the ease of doing business the slogan of government both at national and state levels governance life is becoming easier.

Q: New capacities in packaging paper have come in Southeast Asia, China, and in GCC have really turned down the export of paper from India. Do you think this export decline will remain permanently? Or if not then why?

As already covered earlier demand in China was result of some parading shift in Govt policies and now the situation has normalised. Also, growth in demand in China is not as per earlier times and has slowed down.

Q: Recently, you have been promoted to Vice Chairman of International Corrugated Case Association (ICCA), how do you evaluate the global growth of paper-based packaging? What new trends are taking place around the world? Please explain.

I have always been a champion of cooperation & collaboration for common good and have been active in many associations in Indian and globally. Having headed Federation of Corrugated Box Manufacturers Asso (FCBM) way back in 1989 and then having been instrumental in formation of Asia Corrugated Case Association (ACCA) in mid 90s & then heading that august body in 2003-5; I was instrumental in Making FCBM a member of International Corrugated Case Asso (ICCA). I realised world is fast becoming a global village and neither Indian can keep our not Corrugated industry remain a frog in well.

Q: India is a growing packaging market; please describe your operation in India – your client and strength, Any new product for India on paper-based packaging?

I see Molded Tableware & Restaurant takeaway supplies as major market mover and we are exploring that field as it is ancillary to our current operations. We are looking for right technology to give us an USP.

Another area of interest is Paper bags.

Q: Molded fibre packaging is penetrating the Indian market very fast; it is also being used in heavy goods packaging. How do you compare molded vs. corrugated box packaging? Can we assume molded fibre be the replacement of box packaging in coming years?

Molded packaging not entirely new and has been around for a long time. Till recently packaging of Eggs was its main market, as also separators in bruit boxes. Yes, recently due to Social concerns on replacement of singly use plastics, molded tableware has found tremendous market acceptance. That market will grow exponentially. However, Molded packaging are not a replacement for corrugated packaging, at most they are used as replacement of plastic (EPS) components in corrugated boxes.

Q: What is the shelf life of the molded packaging products and how does it protect inside food products? Does it require any barrier coating?

Molded packaging is still a short-term packaging & tableware solution. It has not found any long term, commercially viable storage solutions for food products, which are dominant buyers of packaging. Lots development on coatings to ensure long term packaging of food products, liquids etc is happening and were are keeping track of same.

Q: Any other message or comment you want to give to Indian Paper Manufacturers?

Paper mills are very ardent business people & know best how to run their businesses. Being a customer & representing their buyer community all I can say is:

1. Look at technical developments to improve performance quality of paper to make better boxes with lesser paper. That will be a win win situation for mills & box plants.

2. Build long term relationships with customers.

3. Let market forces dictate.

4. FCBM has always provided a platform to Paper mills to interact for mutual benefit. Humble request to seize that opportunity and jointly make life better. Neither mills nor box plants can exist in isolation. FCBM has a very vibrant annual conference open to all. Paper manufacturers should participate and learn the issues faced by their customers.

Web Title: “I do not see China being a long-term market for Indian Paper mills, ASEAN countries are having surplus capacities in paper making, with no potential for export” : M L Agarwal

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)