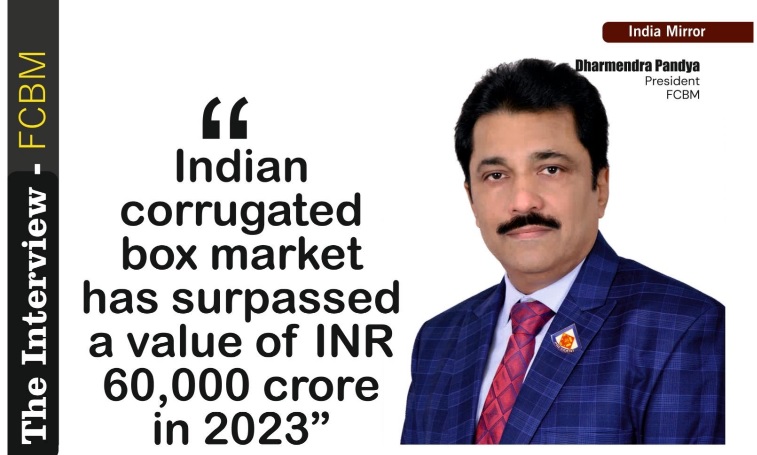

“The presence of surplus capacity in corrugated boxes along with industry fragmentation has diminished the sector's overall value,” says Mr. Dharmendra Pandya, President - FCBM

“The presence of surplus capacity in corrugated boxes along with industry fragmentation has diminished the sector's overall value,” says Mr. Dharmendra Pandya, President - FCBM

Key Points:

- We remain steadfast in adhering to regulatory requirements to uphold our commitment to ESG principles

- The Indian corrugated box sector is encountering difficulties due to surplus capacity, with the main weakness being the excess supply capacity

- corrugated box cannot be replaced by any other packaging material, whether it is biodegradable or compostable plastic-based or wood-based

- Moulded fibre packaging lacks foldability and requires a greater amount of fibres compared to corrugated box production

- We are confident that corrugated board furniture will soon penetrate the market and become a new source of income for corrugators in the near future

- Indian corrugated box market has surpassed a value of INR 60,000 crore in 2023

In an exclusive conversation with The Pulp and Paper Times, Mr. Dharmendra Pandya, President of The Federation of Corrugated Box Manufacturers (FCBM) of India, delves into the intricate challenges and opportunities within the Indian corrugated box industry. Shedding light on the current scenario of packaging trends, Kraft paper prices impact and growth of box industry, He also points out the risk associated with moulded fibre packaging and surplus capacity in the box manufacturing, Mr. Dharmendra shares his invaluable insights into the nuanced landscape of the industry. Here is his full Interview:

The Pulp and Paper Times:

Q: Please give us a brief introduction of The Federation of Corrugated Box Manufacturers (FCBM) of India

The Federation of Corrugated Box Manufacturers (FCBM) of India was established in 1971 and serves as the apex body for India's corrugated packaging industry. It is comprised of 13 regional associations, namely ACCT, EICMA, GCBMA, HPCBMA, KCBMA, KECBMA, MPCBMA, NICMA, PCBMA, RCBMA, SICBMA, UPCBMA, and WICMA, with a membership exceeding 2600 corrugated box manufacturers. FCBM's primary objectives include representing and safeguarding the industry's interests, fostering the development of a sustainable market for corrugated box packaging, conducting research and development, enhancing technological advancements, facilitating the exchange of ideas, engaging with government policies, and more, all pertaining to the corrugated box industry. FCBM holds membership in FICCI and ICCA, further solidifying its position as a reputable and longstanding organization. Recently, FCBM celebrated its 50th Golden Year, a testament to its grandeur, vastness, and the strong camaraderie within the corrugated box fraternity.

Q: How do you see the demand perspective of corrugated boxes in the market? Do you think organic growth of packaging from the market has vanished due to recession or inflation & high interest rate? What is FCBM’s quick review for the present state of the market?

The Indian market for corrugated packaging experienced a significant growth rate of 8% to 10% in the fiscal year 2023- 2024. This growth can be attributed to several factors such as the thriving e-commerce industry, the boom in the FMCG sector, the expansion of the retail sector, and increased consumer preference for lightweight packaging. Additionally, government initiatives promoting sustainable materials have also played a role in this growth. It is worth noting that almost all industries have been impacted by recession, inflation, and high interest rates, as corrugated packaging is a necessary requirement for various products it is also affected. However, the emergence of new opportunities in the market helps to balance the situation. Recent research and surveys indicate that the Indian corrugated box market has surpassed a value of INR 60,000 crore in 2023. It is estimated to have a compound annual growth rate (CAGR) of 9.5% and is projected to exceed INR 150,000 crore in the next decade.

Q: Paper mills are more interested for forward integration by setting up corrugation units in order to increase their margins and consumption of paper, big paper mills are acquiring corrugation plants all across India. Don’t you think that the future picture of box industry will be changed? How does FCBM review this move, especially when the majority of the corrugated box manufacturers are small and medium entrepreneurs?

The corrugated box industry is currently experiencing a significant transformation. This shift is primarily driven by paper mills strategically expanding their operations downstream in the supply chain. These mills are setting up their own corrugation units to gain control over the entire value chain, from sourcing raw materials like Kraft paper to producing the final product of corrugated boxes. This move allows them to maximize their profit margins by capturing profits at multiple stages of production. Additionally, there are a few instances of backward integration, with large corrugation plants establishing their own paper mills. However, these acquisitions and mergers will not have a significant impact on buyers in the middle and lower segments of the industry. These operations downstream segments are relatively small compared to the MSME corrugated box entrepreneurs in India, and therefore, the overall market will not be greatly affected by such transformation.

Q: Any product’s impact comes not just from the product itself but also from how it’s packaged and delivered to the customer. How do you evaluate the perception of new-age consumers about compostable and sustainable packaging? Does the packaging keep an ‘edge’ on the Products?

The increasing importance of eco-friendly and sustainable packaging in the eyes of modern consumers is a significant trend in today's consumer market. However, manufacturers face various challenges such as legislation, inadequate recycling and waste management, and uncertain consumer acceptance when trying to adopt sustainable packaging. Nevertheless, it is undeniable that sustainable packaging provides a competitive advantage to products. Companies that prioritize sustainability not only improve their brand image but also attract conscious consumers. In a crowded supermarket, eco-friendly packaging sets products apart from the competition. Innovative packaging should not only protect and preserve the products but also meet consumer expectations while minimizing environmental impact. The use of micro flutes like E, F, and N in compostable corrugated packaging has revolutionized consumer product packaging, offering aesthetic appeal, branding opportunities, and cost-effectiveness. As a result, it has the potential to greatly enhance the value of products on supermarket shelves.

Q: how does FCBM absorb Environmental, Social and Governance (ESG) in the Packaging, why is it becoming more demanding nowadays?

FCBM’s dedication to ESG principles is pivotal in fostering sustainable growth, upholding social responsibility, and ensuring sound governance in the packaging sector. We prioritize key environmental, social, and governance factors by advocating for the use of sustainable materials like recycled Kraft paper, biodegradable ink, and eco-friendly starchbased adhesives. Our commitment extends to promoting energy-efficient practices such as machinery optimization and waste reduction, alongside harnessing renewable energy sources like solar power. By adopting cleaner production methods and efficient logistics, we strive to minimize carbon footprints. Furthermore, our social initiatives encompass worker welfare, fair wages, safe working conditions, skill development programs, community engagement, and transparent business operations and financial reporting. We remain steadfast in adhering to regulatory requirements to uphold our commitment to ESG principles. The increasing demand for ESG compliance underscores the importance of aligning with consumer values, while also enhancing attractiveness to investors. The evolving regulatory landscape in India further underscores the need for stringent adherence to environmental, labour, and governance standards. We continuously train our members through regular technical programs to ensure alignment with these evolving ESG standards

Q: Indian Kraft paper mills are perplexed with overcapacity issues; due to it they are not able to increase price for the last several months. How does FCBM review the pricing scenario for its raw material?

We have no knowledge of their excessive capacity problems, however, paper mills have significantly raised prices on Kraft paper on a daily basis, citing multiple factors such as the suspension of commercial container traffic through the Red Sea, the conflict between Russia and Ukraine in the Middle East causing an increase in import duties, and the rising costs of local waste. These are the various factors contributing to the uncontrollable situation over the past few months. Our subcommittee diligently and consistently monitors the price fluctuations of raw materials, particularly Kraft paper.

Q: Does the excess capacity issue come up in the corrugation industry also?

The Indian corrugated box sector is encountering difficulties due to surplus capacity, with the main weakness being the excess supply capacity. This oversupply has resulted in decreased pricing leverage for corrugated products. The presence of surplus capacity along with industry fragmentation has diminished the sector's overall value.

Q: After the ban on single use plastic, there has been penetration of several alternatives of plastic packing, such biodegradable and Compostable plastics and wood-based packaging which are competent to carry weight like corrugated box. How do you foresee the future of alternatives Vs corrugated box?

To begin with, I would like to emphasize that the paper corrugated box currently available in the market has no substitute. It cannot be replaced by any other packaging material, whether it is biodegradable or compostable plasticbased or wood-based. The paper corrugated packaging offers a range of unique properties such as 100% recyclability, foldability, different wall thickness options for cushioning and temperature control, hygroscopic ability, and the flexibility to choose Kraft paper combination when designing a box. Additionally, it allows for easy printing and fast production. All these properties make the corrugated box the most practical choice for transport packaging. On the other hand, the introduction of various micro flutes in paper corrugated boxes has replaced the market for paper board packaging, and it is now even used in carton packaging.

Q: Moulded fibre packaging is penetrating the Indian market very fast, it is also being used in heavy goods packaging. How do you compare moulded vs. corrugated box packaging? Can we assume moulded fibre will be the replacement of box packaging in coming years?

Moulded fibre packaging is highly effective in producing food trays, protective inner fitments, and small-sized drums for liquid dyes and chemical products. The term "moulded fibre packaging" itself implies the additional expense of creating die moulds, which ultimately raises the overall product cost. On the other hand, corrugated box packaging incurs a much lower additional cost. Furthermore, paper corrugated boxes remain unmatched in the market and cannot be substituted with any other biodegradable or compostable moulded fibre-based materials. While moulded fibre packaging offers reasonable strength and cushioning for light to medium-weight items, it lacks foldability and requires a greater amount of fibres compared to corrugated box production. We have previously discussed the properties of corrugated boxes. In the short term, it is likely that a combination of both materials will coexist, catering to different market segments based on strength requirements, environmental considerations, and cost-effectiveness. However, this blend will not replace corrugated packaging in the foreseeable future.

Q: Increasing demands of Kraft Paper suppliers to specify RCT (Ring Crush Test) instead of BF & adhere to it consistently. Box manufacturers have started differentiating mills on the basis of consistent quality. How would FCBM evaluate the Kraft paper quality of the Indian Paper Mills on various parameters?

While the use of RCT is becoming more popular, ensuring a consistent and reliable supply of paper for making corrugated boxes requires a thorough evaluation. The quality of Kraft paper must be approached comprehensively, taking into account its evolution over time. Absolutely! The assessment of Kraft paper quality from Indian paper mills involves a meticulous evaluation of various key factors. At our organization level, we have been advocating for improvements in quality and standardization from paper manufacturers for the past 25 years, focusing on enhancing and maintaining fundamental characteristics of Kraft paper such as RCT, BF, liner meter rage, and bad odour. Despite some manufacturers producing satisfactory RCT paper, there is still room for progress. A higher RCT value signifies better resistance to crushing, which is essential for corrugated box packaging during transportation. While there have been advancements in certain aspects, there is still much to be done. It is imperative for mills, especially the newer and larger ones with improved process control, to actively address these concerns with their customers, as such enhancements benefit everyone involved.

Q: The construction of many items utilised in day-to-day living, including as furniture, homes, workplaces, hospitals, and other locations, is another creative endeavour of the corrugation industry. India is lagging behind in the use of products constructed of corrugated material. How does FCBM want to encourage "corrugation formation" in Indian society, which might create a significant new source of income for corrugators as well?

Corrugated board furniture is gaining recognition in the field of interior design due to its unique qualities. This material is made from sustainable renewables, making it environmentally friendly. Additionally, it is 100% recyclable, foldable, lightweight yet sturdy and durable, customizable, cost-effective, and offers an eco-chic aesthetic. I am pleased to introduce myself as one of the few non-packaging article designers in India who specializes in corrugated board furniture. I am dedicated to bringing this innovative furniture to practical use. At the FCBM level, we have been conducting workshops and technical programs to train our members in creating eco-friendly furniture using minimal materials and proper design techniques. FCBM has also published an online reference literature called "Beyond Packaging," which showcases various furniture and non-packaging article designs created by our members. However, there is still a lack of corrugated non-packaging designers, proper design knowledge, utilization of minimal board, availability of odourless, lower-quality virgin Kraft paper, and awareness of corrugated furniture in Indian society. During the Corona pandemic, many members of our FCBM fraternity developed emergency beds, tables, face shields, work-from-home desks, and chairs using corrugated board. FCBM also organizes an annual competition for corrugated board furniture design, recognizing outstanding designs under the categories of beyond packaging and innovation. The CORRUSTAR Awards are presented to encourage our members in their creative endeavours. All these efforts by FCBM aim to raise awareness and establish corrugated board furniture as a trendsetter in society. As Indians, we are always eager to adopt cost-effective innovations as soon as possible. We are confident that corrugated board furniture will soon penetrate the market and become a new source of income for corrugators in the near future

Q: Any message or comment you want to give to Indian Paper Manufacturers?

Our nation faces a shortage of fibre resources. It is imperative for Indian paper mills to enhance their technologies. Both Indian paper mills and society must collaborate to promote recycling in India, following the examples set by Germany and Japan, in order to transition towards a circular economy. We urge paper manufacturers to invest in upgrading their manufacturing technology, produce and distribute high-quality RCT-based Kraft paper with appropriate bulk and Cobb value, free from bad odour, with leaner meter-based reels' formation, and most importantly, ensure consistent supply at fair market prices

Web Title: “The presence of surplus capacity in corrugated boxes along with industry fragmentation has diminished the sector's overall value,” says Mr. Dharmendra Pandya, President - FCBM

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)