Pudumjee Paper Products initiated the exercise to identify suitable paper grades for expansion, focusing on CRM investments and value-added products

Pudumjee Paper Products initiated the exercise to identify suitable paper grades for expansion, focusing on CRM investments and value-added products

-PPPL’s Mahad site is in the process of obtaining statutory clearances that should clear the way for a second greenfield venture.

-Pudumjee Paper continued to utilise available manufacturing capacity, reporting a capacity utilisation of over 89% in 2023-24 ( 80% in 2022-23)

The Pulp and Paper Times

The world of product packaging applications is transforming rapidly, with customers shifting from commodity products to specialized alternatives. Pudumjee Paper Products Ltd (PPPL) leverages its multidecade experience and knowledge to address these evolving needs. Positioned to emerge as a global leader in the production of technologically advanced, environmentally friendly specialty papers, PPPL offers a range of high-quality, customized papers designed for diverse applications relevant to everyday life.

Pudumjee manufactures a diverse array of paper products, including food packaging, decor grades, pharmaceutical-grade papers, super calendared papers, other specialty products, crepe tissue, towels and low grammage printing papers of higher opacity. The Company also provides hygienic hand washers and cleaning equipment to meet our customers’ needs comprehensively. These products serve a primary purpose in establishments such as hotels, restaurants, canteens, and food courts, ensuring hygiene and convenience in various commercial settings.

The manufacturing facility of the Company in Pune possesses an installed capacity of 72000 TPA, the highest speciality paper manufacturing facility in India at a single location. Situated in Thergaon, Pune, the Company’s manufacturing facilities produce a diverse range of specialty papers covering a wide range of grammages (g/m2).

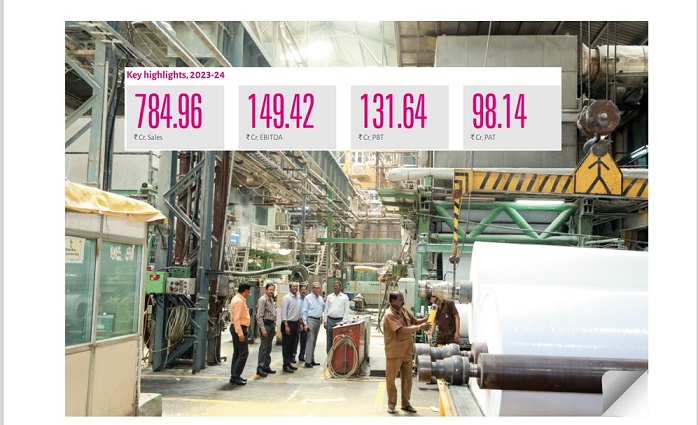

The record performance reported by Pudumjee in 2023-24 was the outcome of a strategic clarity. During the last number of years, PPPL focused on specific priorities that have begun paying off in a bigger way than ever. In 2023-24, PPPL reported profitable growth: revenues increased 3.46% while EBIDTA increased 52.62%; EBIDTA climbed 654 bps to 19.04% and Return on Capital Employed strengthened from 17.45% to 25.37%. These outcomes indicate a deeper maturing.

“The Company continued to advise, co-develop, and produce specialized paper used across brand-critical applications—hygiene in foods, health in pharmaceuticals, and protection in consumer products. As a result, an increasing number of customers came to us, not seeking ‘another 1,000 tons of any paper,’ but a ‘grade of paper customized around our specific needs,’” said Mr. Arun Jatia, Chairman of PPPL, in the Annual Report for FY 23-24.

Mr. Jatia further stated that the Company continued to play the ‘uncommodity’ game, marked by servicing a larger number of orders with smaller production runs, integrating itself deeply into the businesses of customers who represent the next round of growth in an expanding economy.

Pudumjee increased the service component of its solutions-based delivery, which translated into a realisation that was considerably higher than the paper industry average and repeat engagements with the same customers.

“At Pudumjee, we are excited about addressing the unprecedented growth and maturation of the market in India. Our optimism about India stems from a range of factors that we consider sustainable and enduring in nature,” Mr. Jatia said.

Mr. Jatia stated that the biggest visible consumer change in the last few years has been a growing preference for hygiene across virtually all consumer products and services. This has been most pronounced in improved food delivery standards, influenced by an expansion of global and Indian QSRs brands on the one hand and the Indian consumer demanding a safer consumption experience on the other.

On the future expansion at Pudumjee, Mr. Jatia informed that following the rapid growth of Pune in the last couple of decades, we are now being seen as an urban mill with no expansion possibilities. The only plausible expansion possibility will lie in the identification of a second location in close proximate to Pune and provides us with a large headroom for our proposed next growth round. PPPL’s Mahad site is in the process of obtaining statutory clearances that should clear the way for a second greenfield venture.

“We believe that the proposed expansion, when firmed, will graduate our company to the next orbit for various reasons. It will enhance the confidence of our customers that we would be in a position to service their growing appetite for specialised packaging grades, accounting for a larger share of the customer’s wallet. We will be empowered to leverage our rich subject matter competence across a larger production base. We will be able to explore the development and manufacture of a wider range of technology driven products that we are presently unable to address on account of limited manufacturing capacity. We will remain focused on the manufacture of customised products as opposed to integrating backwards into the manufacture of pulp due to constraints of fibrous raw material availability in close proximity of our location,” Mr. Jatia said in the annual report.

He stated, "We believe that the incremental capacity in the foreseeable future will be funded largely through the cash available on our books, complemented by moderate debt, which is expected to enhance competitiveness from day one. In light of this, we foresee an attractively sustainable future—from national, sectorial, and corporate perspectives—that should enhance value for all those associated with our company."

Regarding Pudumjee’s performance, Dr. Ashok Kumar, Executive Director of PPPL, said that although company’s net sales realisation was lower at INR 1,22,295 per MT during the year under review compared to INR 1,28,418 per MT last year, the overall value-addition during the year under review was higher. This realisation transpired at a time when most paper segments reported lower realisations, validating our product and strategic differentiation. The improvement in realisation was the outcome of a patient strategic direction including helping our customers by way of giving advice and support to use the right product for their end use applications. This helped in taking their business ahead while addressing the demanding needs of customers at the same time which helped them and also to the Company to derive a superior price-value proposition from their engagement with us. I am pleased to communicate that all these boxes were successfully ticked during the last financial year which translated into more value-added realisations and thus cascading to an overall increase in margins and capital efficiency.

“Pudumjee Paper continued to utilise available manufacturing capacity, reporting a capacity utilisation of over 89% in 2023-24 ( 80% in 2022-23). In a business marked by short production runs and frequent product change overs, we see this improvement as an index of our ability to manage diverse operational factors. Besides, Paper Machine No. 6 (PM-6) was utilised more this year compared to the last year, the benefit of which translated into overall increased output,” Dr. Ashok Kumar said.

Regarding the outlook for the Company during the current financial year, Dr. Ashok Kumar stated that we expect to sustain the improvement in performance on the basis of marginally enhanced production, which is expected to counter the increase in cost of pulp that will need to be acquired to sustain operations through the second half. We foresee increased imports of paper affecting realisations specific to speciality papers and tissue grades. We will continue to exercise cost control. Some decrease is expected in electricity costs partly derived from a larger renewable energy share. We will continue to modify our product mix with the objective to enhance overall realisations and profitability.

“At Pudumjee, we recognise that the focus would be to address the volume end of this transforming market. We will also continue to market products that are challenging for others to develop and manufacture in line with demanding specifications. This requires the significant increase of the role of research in product development that provides customers with alternatives equal to or superior to single use plastic packaging. In view of this, we are faced with a large growth headroom ahead of us,” Dr. Ashok Kumar concluded.

Revenues :

The Company is positioned as an international speciality paper producer located in India. The Company services the growing demand of customers across 11 countries. Nearly 2.13% of the Company’s revenue was derived from international dispatches, a reflection of its growing competence and confidence and ability to service the market with a timely supply of quality material. India was the Company’s largest market, accounting for 97.87% of revenues. Revenues from customers of five years or more accounted for 76% of the Company’s revenues, indicating the relationship-driven mode of business enhancing revenue visibility.

Realisations:

The Company has consistently enriched its portfolio through the manufacture of value added specialty packaging paper, translating into wider value addition by way of higher realisations. Although realisations per MT of paper segment declined, value-addition improved during the year under review. The increase in realisations and premiumisation was the result of customers selecting to graduate to superior specialised packaging paper grades on account of increased awareness related to food hygiene, product protection and presentability.

Outlook, 2024-25

Pudumjee Paper plans to produce approximately 70,000 MT, subject to changes in grammage and product mix, through optimised production planning, unplanned downtime reduction, optimised utilisation of PM-1 and PM-2 and focus on value-added products. Pudumjee aims to capitalise on the momentum. Despite the anticipated challenges in the business environment in 2024-25, the Company’s investments in customer relationship management are expected to sustain growth.

Pudumjee will continue to focus on procurement, emphasising efficiency, sustainability, resilience and innovation. Through the integration of technology and sustainability, the Company seeks to fortify its supply chain to navigate challenges and capitalise on emerging opportunities. Prioritising supplier base diversification, risk management implementation, and supplier relationship sustainability will help mitigate supply chain risks and ensure uninterrupted raw material supply. With a commitment to source raw materials from sustainable and responsibly managed forests, including collaboration with FSC certified suppliers, the Company will pursue cost optimisation and responsible procurement.

India’s growing economy is encouraging the offtake of quality packaging paper across a diversified market. In view of this, the Company initiated the exercise to identify suitable paper grades for expansion following timely capital expenditure at its 75-acre Mahad site.

Key highlights, 2023-24

- Production nearly returned to pre-COVID levels (64305 MT)

- Enhanced process efficiencies, minimised waste and improved product quality, enhancing customer satisfaction.

– Addressed about 13% power requirements from within through solar, wind and cogeneration. - Decided to establish a 15 MW (DC) solar power plant

- Responsible water use led to a continuous reduction in unit water consumption (from 28 m³/MT of paper in 2021-22 to 22.1 m³/MT in 2022-23 and 18.5 m³/MT in 2023-24).

- Improved PM-6 tissue machine uptime by producing virgin tissues alongside existing recycled grades.

- Generated superior acceptance of the food-grade segment following the introduction of solid bag and solid wrap varieties.

- Installed a TDR system on PM-1, primarily for Décor Grade papers, which improved the recovery of the costly TiO2 chemical Modified the water circuit to minimise freshwater consumption

Web Title: Pudumjee Paper Products initiated the exercise to identify suitable paper grades for expansion, focusing on CRM investments and value-added products

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)