BioCNG from paper mill effluent: India’s & Asia’s First Paper mill, Sainsons Paper to Produce & Sell CBG/BioCNG From Waste Water

BioCNG from paper mill effluent: India’s & Asia’s First Paper mill, Sainsons Paper to Produce & Sell CBG/BioCNG From Waste Water

-Sainson's management vision for the "First in Asia" project is to produce BioCNG from paper mill effluent.

-This plant is commissioned at Sainsons Paper Industries Pvt. Ltd. and, reducing carbon emissions & helps to make additional profit by selling the BioCNG.

The Pulp and Paper Times | 2023:

Sainsons Paper Industries Pvt. Ltd. is one of the largest manufacturers of Semi Kraft Paper with Agro Waste and Indian OCC of North India. The company is located at Pehowa (Distt.Kurukshetra) in Haryana and production capacity of 350 TPD.

Many thanks to Mr. Pradeep Saini (Managing Director), Mr. Harikrishan Saini (Director), Mr. J.N. Saha (Vice President), Mr. Raj Kumar (General Manager) and Sainson’s team who helped us in completing the project successfully. Sainson's management vision for the "First in Asia" project is to produce BioCNG from paper mill effluent.

KIS Group is a leading technology provider, equipment’s manufacturer and focuses on climate change efforts through Energy transition & Decarbonisation of various Industries such as Agricultural waste, Sugar, Palm, Rice, Paper Industry, MSW, Cow Dung, poultry waste, Napier Grass etc. in a responsible manner by adopting advanced technologies with reduced dependency on fossil fuels., with numbers of installations in India and Worldwide.

This plant is commissioned at Sainsons Paper Industries Pvt. Ltd. and, reducing the carbon emissions & helps to make additional profit by selling the BioCNG, also with this Sainsons become the first paper mill to sell vehicle grade BioCNG®. The profit of BioCNG is much higher than burning biogas in boiler. This project helps paper industry to remain competitive, profitable and reduce Emissions.

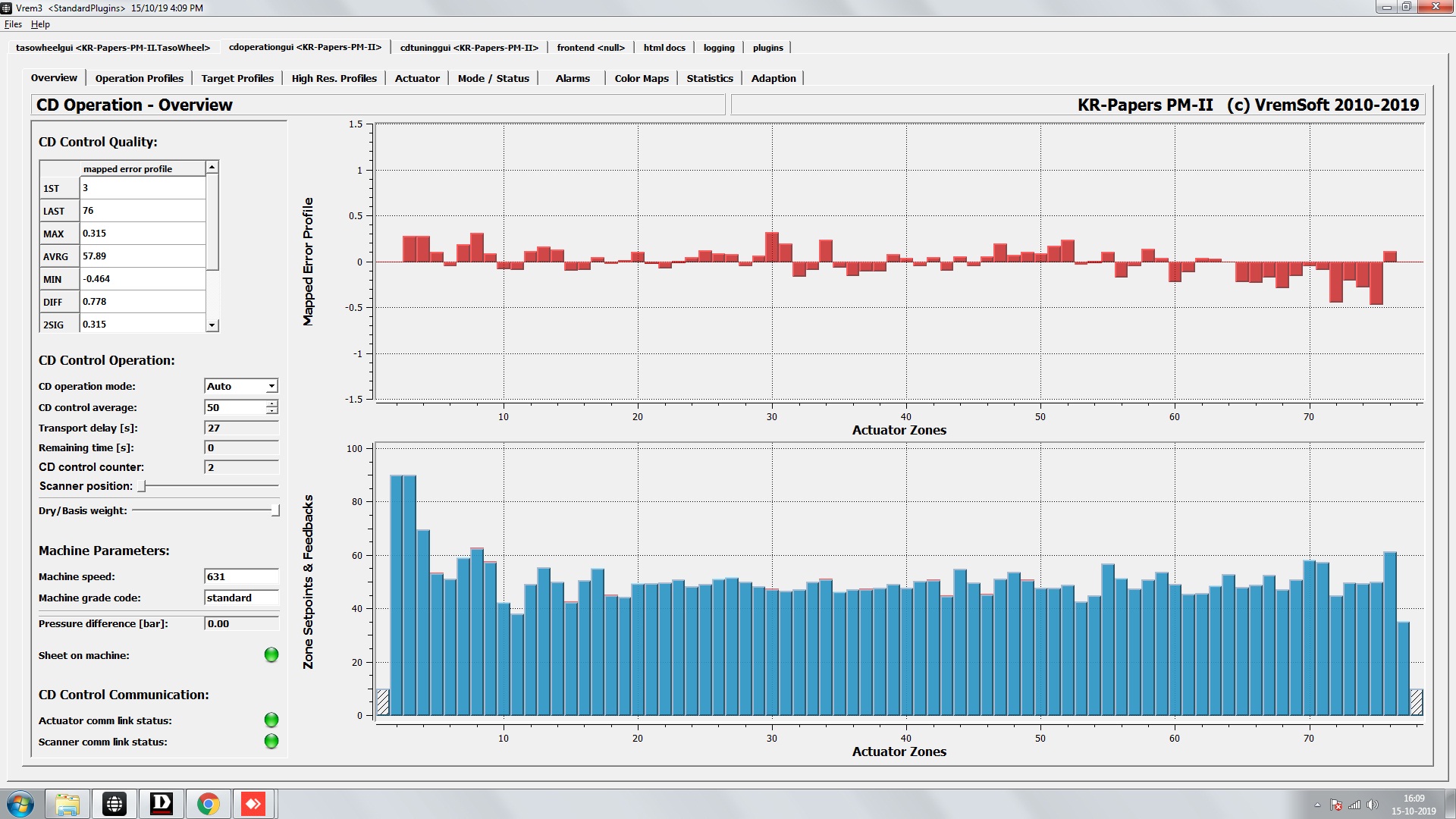

Below is the schematic flow of the process;

1. Feedstock :

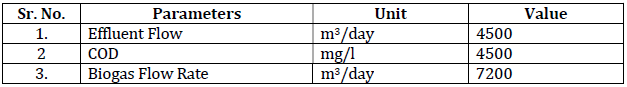

Paper Mill Effluent (from wet washing for raw material (wheat straw) and paper machine Backwater.) The installed higher-rated Anaerobic digester has design capacity of 18 MT COD load and flow of 4500 m3/day at COD is 4500 mg/l. The COD reduction is in the range

of 65-70% for the digester and raw biogas generation in the range of 6000-7000 m3/day with methane content 60-70%, which is presently being flared.

2. Process/Technology

A. Removal of Sulphur from Biogas : The raw biogas from the existing anaerobic digester is send to the proprietary scrubber system for the removal of H2S content. Raw Biogas has H2S of around 20,000 ppm and its reduced to almost 0-5 ppm from our Patented BioClean® Technology. The process is a modified liquid red-ox process to remove H2S in Biogas using chelated polyvalent metal ions with a stabilizing agent.

Pure Sulphur Recovery: The sulphur present in the hydrogen sulphide is precipitated as elemental sulphur, which has commercial value as fertilizer (Purity is >97%).

Patented Chelating Scrubber? Storage of Clean Biogas in Double Membrane Gas Holder: The purified biogas after the scrubber is collected in the double membrane gas holder as a buffer before taking into the biogas upgradation system.

Pure Sulphur Recovery and Purified Biogas Holder

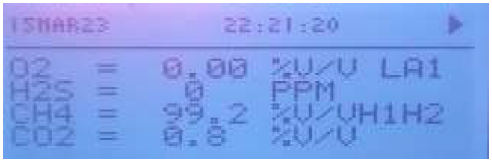

B. BioCNG Generation (PSA)/CO2 Removal Process : The biogas is entering into the Four Tower Technology- Pressure Swing Adsorption System, the raw purified biogas is passed through different units like Desulphrizer, moisture separator, Chiller, Pre-Filters, GDU units & PSA Towers. After Passing through all these systems methane is purified to the purity of 98%.

The CO2 is removed through PSA system by molecular sieves. The removed CO2 is vented off to the atmosphere but in future , we can capture the enriched CO2 further by removing the impurities, and can be used in industrial application.

Our Unique 4 Stage CO2 Removal system almost removes 98% -100% CO2 without methane loss to get recovery of 97%-99% purity.

The output after cleaning and upgradation is mentioned , we are getting Methane with purity more than 99%, a high grade fuel, during performance trials.

c. Commercial Sale of Vehicle Grade CBG/BioCNG : Proprietary

The compressor takes the gas from the storage tank stored in cylinder cascades to supply BioCNG to the nearby Oil Company Petrol pump to sale BioCNG fuels in vehicles. The mill has already entered an agreement with HPCL to sell the BioCNG. The final product specifications is adhering all the quality and safety guidelines as notified by Government (IS 16987 : 2016).>>P54<<P15

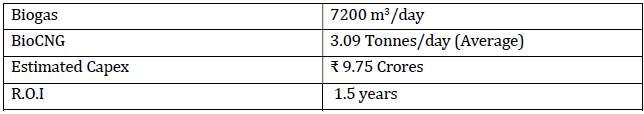

3. Typical R.O.I (Cost Economics) for Paper Mill BioCNG Project :

Below is the typical R.O.I for Complete BioCNG Plant for the existing Biogas projects; in which Capex includes mainly is Scrubber System, Biogas Management System, PSA System & related equipment’s/ instruments.

*Note : The calculations are inductive in nature & may vary depending upon the size & variable parameters.

"The paper industry is currently facing significant challenges, but it also presents an excellent opportunity. With the implementation of this commercially proven project, all paper industry players can remain competitive, profitable, and reduce emissions."

K.R.Raghunath

Managing Director

Web Title: Waste To Energy India’s & Asia’s First Paper Industry to Produce and Sell CBG-BioCNG From Waste Water

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)