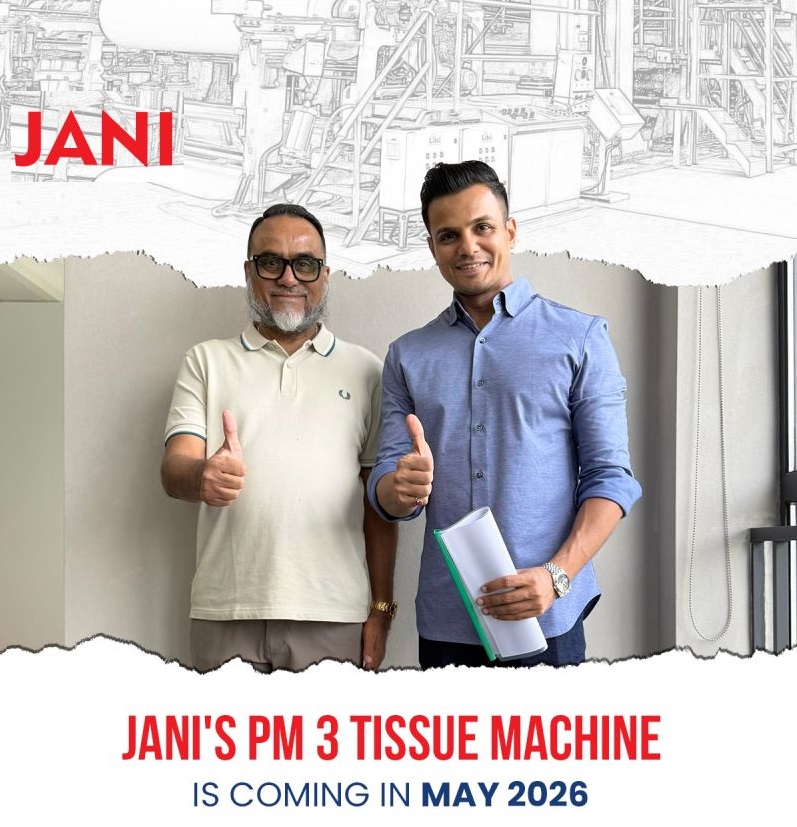

Jani Sales to Jostle the Tissue Paper Market With 100 TPD Mega Capacity

Backward Integration: Waste Paper Supplying, Paper Sales Network And Now Manufacturing; Jani Sales to Jostle the Tissue Paper Market With 100 TPD Mega Capacity

Mumbai | 1st January 2020 | The Pulp and Paper Times:

With four decades of trading experience in paper and paper board industry, Jani Sales is gearing up to emerge as leading Tissue Paper manufacture in India. “We started our company viz Jani Sales Pvt. Ltd. in 1979, and now we have completed 40 years in the paper industry. It's a celebration and milestone achievement for us. We sell packaging grades majorly in the Indian market and export markets. As a group company business, we also source waste paper from the United States and U.K. and supplying it to Indian Paper mills and many Asian mills. We do trading of 5,00,000 tonnes of waste paper in a year and more than 2,00,000 tonnes for finished paper business,†Said Mr. Saifee Jani, Chairman, Jani Sales Pvt. Ltd.

“We are very excited to do backward integration of our business. We have a waste paper supplying channel, we have a good sales network and now we are entering into tissue paper manufacturing with mega capacity. We are putting up 100 TPD tissue, MG Poster, and MG Kraft unit in the western region with start-of-the-art infrastructure,†Mr. Jani informed to The Pulp and Paper Times in an exclusive interview.

“We are targeting to start the production by the end of March 2020,†Mr. Abiali Jani, Director, Jani Sales further informed.

Tissue segment has the highest ever growth in the paper sector, growing awareness about hygiene creating a good scope for Tissue consumption in India. “We always wanted to make a remarkable entry in paper manufacturing and decided to come in the market with niche products. After analyzing the present market condition and the export experience we decided to enter the market with MG grades segment, where we see a good scope of future considering the single-use plastic ban and major changes in awareness related to environmental issues, our focus would be to cater these kinds of applications to our best†Mr. Saifee added.

“We have deployed the best machine and equipments for getting the highest quality standards of the paper. We have a perfect combination of mixes of products, where we can manufacture 100% virgin products, 100% recycled products, and a mix of recycled and virgin products as well. “Mr. Abiali further informed.

Jani Sales has 4.2 meter wide deckle of the machine and the speed of the machine is designed at 900 m/min.

The new unit will produce Tissue, MG Poster, and MG Kraft paper on a single machine with 17 to 85 GSM range. “We are planning to manufacture all lower GSM paper on this speciality machine. Our range of products will consist of Kitchen Towel, Napkins, and Toilet Tissue-based on recycling waste paper and virgin pulp both,†Mr. Saifee said.

According to studies, the consumption trend of tissue paper products in the metro cities is very different from the smaller cities and towns in India. Rural India mainly consumes MG poster (also called hard paper) in its paper napkins. Though this quality of the paper is not at all absorbent to water, it is still extensively used here because of the cost factor. Tissues in India, on the whole, are still considered more a luxury item than a commodity. As a category the sales of paper napkins is maximum, and facial boxes the least.

Quick Questions & Answers Session with M.Saifi Jani

Q.The Indian government is planning to implement a one percent limit for the contamination on mixed waste paper imports to India, How do you see this step of Govt. in terms of easy availability of waste paper? Will this step create a hurdle for paper mills?

We believe that we should support the government with whatever policy it tries to implement which will be good for the environment.

Q. Being a reputed Paper Trader how you take Govt. decision of doubling the import duty on coated paper and paper boards. Will this decision impact the supply of coated paper in the market?

This is a positive step in making the local mills stronger as they were financial bleeding due to the dumping by the various countries in the Indian Market.

We as a country are manufacturing all kinds of papers and have become self-sufficient, the above step will help the mills to be financially viable thus encouraging fresh investment in the industry and capacity enhancement. The generation of employment in the paper sector will also increase.

The financially sound paper mills will lead to export the paper out of India, this step would bring much needed foreign exchange and improving our trade balance deficit if any.

Q. What paper trade facilitation do you expect as a paper manufacturer and how do you evaluate that trade facilitation as a paper trader?

As a trader, the step of doubling the import duty will help us to promote the local mills better. As a manufacture we would like to bring into attention some of our views:-

Paper Industry is a capital intensive sector, a substantial investment which is required to be made. The burden of GST of 18% while setting up a paper mill takes the cost up by approx. 18%. We understand that this money is returned to us once we start manufacturing, but during the project period our major part of capital is trapped with the government, this becomes a major bottleneck for any new investor.

Moreover, the situation becomes more severe when bank loans' interest also starts immediately. It is a challenge for a paper mill to handle the financial cost at the 'initial stage' when production is not started.

What we recommend the government is to postpone the project-based GST payable to them and be made payable once the company starts production or make the payment of GST more flexible so as to encourage investment in the sector.

Q.Bad debt in the paper trading business is becoming a big headache for the paper traders. How do you address this bad debt problem as a manufacturer and what solution do you provide as a paper manufacturer to the paper traders to come out of this "debt trap"

The problem starts with oversupply in the market due to local production and imports of paper. This creates a major tug a war between mills to sell their products which they are by force their agents to sell paper even to people without any major financial standing. This, in turn, creates the bad trap.

We believe the Government must bring an environment of 'Credit Insurance' that will save our receivables, and help the trader make more learned decisions. Also the credit rating system among the buyers should be put in place. One can aware about the credit rating of a buyer before giving the goods on credit. This rating system will motivate paper traders to work hard for themself and the mills they represent. This will thus help the overall economy.

Web Title: Jani Sales to Jostle the Tissue Paper Market With 100 TPD Mega Capacity

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)