Newly started, Maakrupa Paper mill is fulfilling Corrugators' demand in Central India

Newly started, Maakrupa Paper mill is fulfilling Corrugators' demand in Central India

Indore | 5 January 2021 | The Pulp and Paper Times:

Based on packaging form, the corrugated segment is projected to dominate the kraft paper market, in terms of value and volume, from 2019 to 2025. The Lockdown and the continuing of an economy back toward full production; new capacities in kraft paper production are taking place. The demand of corrugated boxes have been rising, corrugated boxes not only offer protection to shipped goods from damages but also offer easy handling features.

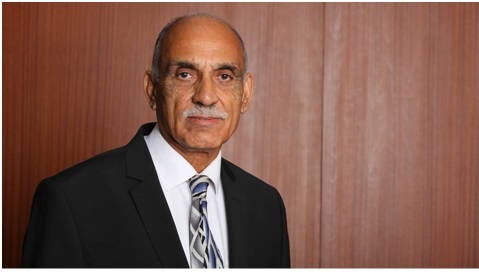

"The COVID-19 pandemic has changed the normal functioning of the packaging industry as demand for specific packaging types witnessed major disruptions. The packaging demand used in healthcare products, groceries, and the e-commerce sector has increased sharply. At the same time, the demand for luxury, industrial, and some B2B-transport packaging has declined. Due to lockdown in many countries across the globe, consumers have opted for online shopping of groceries, medical products, pharmacies, and other consumer goods, affecting the retail ready packaging market," explained by Mr. Alpesh Ramani, Director at Maakrupa Paper Products LLP a newly started paper mill.

"The demand of kraft paper will remain sustainable in the future, and we are glad that our investment in new paper mill will yield good returns for us. There are less paper mills in Indore region, which is making us a viable option for corrugators and Traders' buying need of paper. We have installed and commenced a 120 TPD paper mills at an industrial area which is 12 KM away from Indore," informed by Mr. Alpesh.

Maakrupa Paper has commenced its production in December 2020 at 80 TPD and gradually increasing its capacity. "We are manufacturing paper between 110 to 150 GSM with 16 to 20 BF strength," Mr. Alpesh said.

He further insisted that corrugated boxes are the lifeblood of the modern packaging and shipping industries. Think about it; almost everything we touch has been packaged, moved, delivered, and received in a brown box.

“Our entire plant and machinery is supplied by DS Engineers, DS Engineers helped us in customizing the plant and machinery according to our need of paper quality. We have also installed all the critical components which are useful in automated the paper mill for reducing manpower,†he said.

The new plant has 3.8 meters finished deckle size while speed is designed at 250 m/min.

We have bought the entire pulp section from Parason Machinery.

Mr. Alpesh further informed that our machine is running on a single wire machine and having the capability to reach at 130 TPD. We are currently selling our products in domestic market, and looking for an export market also.

Corrugated is made from three layers of thick paper stock that are glued together. Two flat outside pieces called liners have a layer of grooved cardboard sandwiched between them. The wavy piece of paper stock is called fluted cardboard, and it comes in different sizes to provide different levels of strength.

Web Title: Newly started Maakrupa Paper mill is fulfilling Corrugators demand in Central India

More News From new-projects-and-expansion

Next Stories

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)