Alternative Products and Technologies to Plastics: Is Paper really alone?

Alternative Products and Technologies to Plastics: Is Paper really alone?

- An Interesting study on Plastic and its alternative

- India would become the largest mismanaged plastic waste (MPW) generating country by 2035, and the demand would reach 46.3 (38.6–52.0) MT/yr by 2060, followed by China with 33 (28.1–36.8) MT/yr.

New Delhi | July 2022 | The Pulp and Paper Times:

Single-use plastics (SUP), often referred to as disposable plastics, are commonly used for plastic packaging and include items intended to be used only once before being thrown away or recycled. Keeping in view the adverse impacts of littered plastic on terrestrial and aquatic ecosystems, in 2019, Prime Minister Shri Narendra Modi issued a call to phase out SUP by 2022. Subsequently, the government has adopted a three-pronged approach in tacking this problem, viz. behavioural change, institutional mechanisms, and extended producer responsibility.

In India, packaging materials account for 24% of the total domestic consumption of plastic, followed by agriculture at 23%, and household items at 10%. Data from the packaging segment data reveals that PE and PP account for around 33% and 29% of polymer usage respectively, followed by polyethylene terephthalate (PET) at 17%, polyvinyl chloride (PVC) at 7%, and others at 14% in this segment. Finished plastic products also constitute a significant component of value-added product exports.

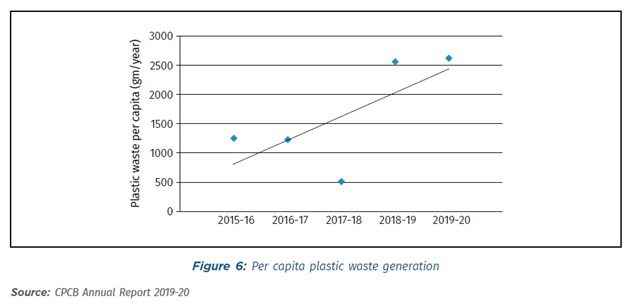

India produced approximately 3.47 million tons of plastics waste per annum, as per the Central Pollution Control Board (CPCB) report with the per capita waste growing from 700 gms to 2500 gms over the last five years. Unfortunately, only a small amount of this plastic waste gets recycled. A majority of this waste leaks into the environment through various polluting pathways. India collects only 60% of its plastic waste with the remaining 40% remaining uncollected and enters the environment directly as waste. These numbers are relatively small compared to developed nations but these trends are not sustainable given simply the volume of plastics in India. Alternatives to plastics will play a significant role going forward.

In view of this, NITI Aayog, under the Chairmanship of Hon’ble Member Dr V.K. Saraswat, set up a committee to identify alternatives to plastics as well as technologies that make plastics biodegradable. The committee also assessed infrastructure needs, market readiness, and appropriate regulatory and policy approaches to facilitate the transition to plastic alternatives and sustainable plastics. The relative advantages and disadvantages of substitution, conversion technologies, and necessary procedures were carefully considered while developing alternatives.

Since their invention, plastics have transformed the way we live and have become omnipresent in our lives: be it clothing, transportation, communication, health care, manufacturing equipment, money, or almost any other sphere of life.

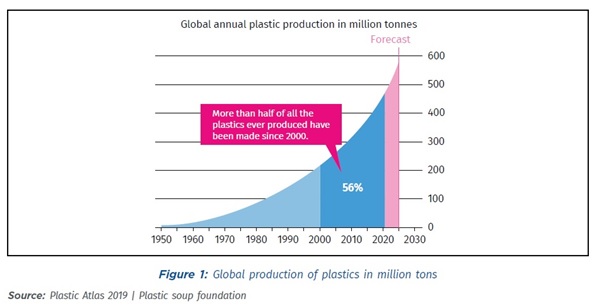

Globally, 97-99% of these plastics are derived from fossil fuel feedstock while the remaining 1-3% come from bio (plant) based plastics8. The amount of plastic that is produced in the world every year has increased exponentially in just a human lifetime, i.e. from 2 million tons in 1950 to 381 million tons in 20159. production. The global per capita consumption (2014-15) was 28 kgs. More than half the total amount of plastic produced was only brought to market after 2000. The expectation is that production will further increase to about 600 million tons in 2025 (Figure 1). This is roughly twice the total weight of the world’s population today10! The packaging industry dominates the consumption by about 42%, followed by the building and construction sector utilizing 19% of the total plastic created.

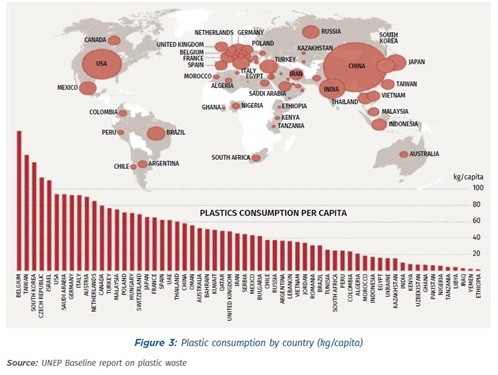

China is among the most prominent plastic consumers accounting for 20% of the global plastic consumption and is followed by Western Europe, which accounts for 18% of the worldwide plastic consumption and then United States of America (USA). However, in terms of plastic consumption per capita, China is ranked much lower than other countries. On the contrary, the European Union (EU) is one of the largest per capita consumers of plastic (Figure 3).

Indian Plastics Industry:

The Indian plastics industry started in 1945 and has been growing over the years. From 0.9 million tons in 1990 to 18.45 million tons in 2018, plastic consumption has grown 20 times since then. The plastics industry is one of the biggest generators of employment in the country, valued to be around INR 5.1 lakh crore (USD 73 billion).

There are over 30,000 units that produce plastic materials in India. Approximately 90% of these units are small and medium-sized enterprises. The Plastic industry employs about 4 million people. In Financial Year (FY) 20 (till January 2020), plastic exports stood at USD 7.045 billion, with the highest contribution from plastic raw materials at USD 2.91 billion; plastic sheets, films, and plates at USD 1.22 billion; and packaging materials at USD 722.47 million.

Environmental Impacts of Plastics:

Plastic overconsumption and mismanagement is a growing menace across the globe and is leading to overflowing landfills, blocked rivers, and threatened marine ecosystems. Most global plastics waste is generated in Asia but the US, the EU, and Japan lead in terms of per capita plastic packaging waste.

As per the 2018 UNEP report, plastic litter in the Asia-Pacific region alone costs its tourism, fishing, and shipping industries USD 1.3 billion per year. In Europe, cleaning plastic waste from coasts and beaches costs about €630 million per year. Studies suggest that the total economic damage to the world’s marine ecosystems caused by plastic amounts to at least USD 13 billion every year. Thus, the economic, health and environmental reasons to act are clear.

Trends in India:

Approximately 3.4 million tons per annum of plastic waste was generated in India in 2019-20 while the per capita waste generation trend for the last five years (2016-20) has almost doubled over the previous five years (figure-6). Goa, Delhi & Kerala have reported the highest per capita plastic waste generation, while Nagaland, Sikkim and Tripura have reported the lowest per capita plastic waste generation.

Globally, between 10-60% of plastic waste gets recycled across different countries; it averages 30% in most countries in the EU and only about 10% in the US. Additionally, in many developed nations, a larger fraction of plastics waste gets thermally treated to recover energy as opposed getting recycled for material recovery.

India does better in this aspect due to a large informal sector workforce (comprised of individual waste pickers and waste traders) making a living by collecting, sorting, recycling, and selling valuable plastic materials recovered. Approximately 60% of plastic waste gets collected for recycling and recovery in India, which is much higher than in developed countries.

Plastic Alternatives:

As per a research study by Laurent Lebreton & Anthony Andrady, future demand (Figure 11) for plastic will nearly triple by 2060. India would become the largest mismanaged plastic waste (MPW) generating country by 2035, and the demand would reach 46.3 (38.6–52.0) MT/yr by 2060, followed by China with 33 (28.1–36.8) MT/yr.

Some of the other sustainable alternatives that should be considered to deal with plastic waste are to use of biodegradable plastics, biodegradable bioplastics, and compostable plastics. These provide an alternative to conventional plastic usage, though often, there is confusion about the differences among the terms bioplastics, biodegradable plastics, compostable plastics, and oxodegradable plastics.

Bioplastic: encompass many materials that are either bio-sourced or biodegradable or both and are made from renewable biomass resources, most often corn starch/ sugarcane/ cassava – which might be either biodegradable or not.

Bioplastics constitute about 1% (or 2.1 million metric tons) of all the plastics produced annually according to the industry association European Bioplastics. Although this represents a small fraction of plastic production, bioplastic production is expected to increase by 300,000 metric tons between 2019 and 2024. Bioplastics could address the need to reduce fossil fuel consumption however, they do not address plastic pollution, especially in marine environments.

Biodegradable plastic:

Recently, there have been emerging technologies that have developed additives, that when used in the formulation, make it possible to manufacture completely biodegradable polyolefins such as PP and PE. These biodegradable plastics are evolving as a potential alternative to conventional plastics. Biodegradable plastics are recyclable, which reduces negative environmental impacts and enhances economic sustainability. These plastics, if due to some reasons, are not picked up for recycling, biodegrade in the ambient environment. At present, both aerobic as well as anaerobic biodegradable plastics are available.

A UK-based company has developed an additive which, when added to the masterbatch of polyolefins, i.e., PE and PP, onsets the degradation. The plastic weathers to a biodegradable wax, a non-toxic substance on which microbes feed, leaving no microplastics. Known as the “biotransformation process”, once active, it combines the effects of light, air, and moisture to create a catalytic effect that causes the polymer chains to lose over 90% of their original structure (Figure 13). The dormancy period of the technology is created by balancing the stabilizers with active ingredients to allow use, reuse, and recycling.

Polypropylene-based speciality film

A Malaysian company has developed a technology on anaerobic biodegradable PP-based speciality film and this has been tested at the Eden Research Laboratory, USA. This new PP has achieved 84% biodegradation64. The testing of the further improved film has been initiated in India and has shown promising results.

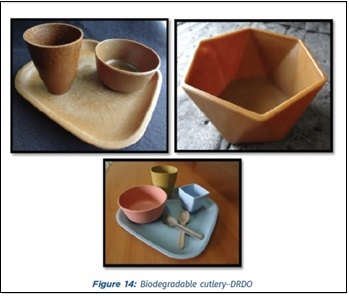

Biodegradable cutlery

Defence Research and Development Organisation (DRDO) Lab DFRL has developed technology for biodegradable cutlery (Figure 14). It is produced through the reinforcement of natural fiber agrowaste) into matrix/resin, which is a polymer of renewable resources and is formed through a compression or injection process. Biodegradable tableware (spoon, fork, spork, bowl, khullad, plate, teacup) can be used as an alternative to plastic tableware as natural biopolymers offer significant benefits such as degradability, biocompatibility, and biological safety as compared to plastic that persists in the environment with environmental hazards. The biodegradable cutlery is suitable for serving hot and cold meals. Biodegradability occurs within 180 days and is compostable in 90 days in the natural environment.

A renowned industrial firm in India has developed a novel process for biodegradable plastic (TRL 6 level65). The developed PBAT grades showed good performance in terms of physical and mechanical properties. The developed grades are also compounded with various fillers for ease of downstream processing and enhancing product properties required for applications in flexible as well as rigid packaging and agriculture mulch films, among others.

Compostable plastics:

Presently, over 150 compostable plastic manufacturers have been certified by CPCB, and they are manufacturing a wide range of products, including films, bags, cutlery items, straws, gloves, aprons, thermoformed products etc. The installed capacity of the compostable plastics is approximately 3,00,000 TPA, and the list of certified compostable plastics is available on the CPCB website.

DRDO & Ecolastic Products Pvt Ltd (Hyderabad) have jointly developed technology to make compostable plastics. This technology of starch-based compostable bags/films is being commercialized and it is competitive and meets the performance requirements of most short-life applications. This technology for making bags, cups, plates, molded cutlery and toothbrushes, thermoformed boxes, etc., is ready and already in commercial use in places such as Tirupati for Prasadam bags.

Edible Seaweed Cups

Seaweed can grow up to 60 times faster than land-based plants, making it an important carbon sink. An Indonesian company, in 2016, in response to the plastic waste crisis, made edible seaweed cups under the Ello Jello brand that come in various colours and flavours, from orange to green (Figure 15). The company also produces edible food wrapping and single-use sachets, typically used for instant coffee or food condiments.

Algae-blended ethylene-vinyl acetate

A US based firm has created algae-blended ethylene-vinyl acetate transforming air and water pollution (ammonia, phosphates, and carbon dioxide) into plant biomass rich in proteins. The material called Bloom, a bouncy and flexible foam is used in the soles of most shoes (Figure 16). It replaces the incumbent material traditionally made from petroleum.

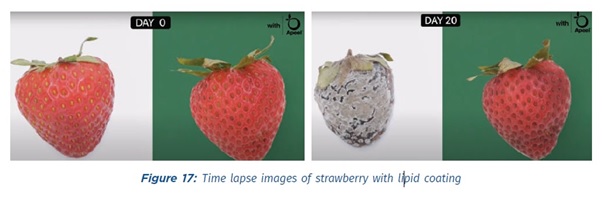

Lipids and Glycerolipids Coating

A California based company has formulated a plant-derived (lipids and glycerolipids) edible, odourless, colourless, and tasteless coating (Figure 17). This can help in eliminating the packaging of fruits and vegetables and increasing the shelf life.

Zero plastic recycled paper bottle

A UK firm69 has invented the only commercially available zero plastic recycled paper bottle in the world. From seal packing to the inner lining of the bottle, everything is made from a sustainably sourced material (Figure 18). Feasibility studies are carried out to design for each product and use across multiple industries, from pharmaceutical & cosmetics to foodstuffs & drinks and home care and cleaning products. The company was recently acquired by HP Inc.

Edible packaging products

London based startup has made seaweed-based sustainability packaging material that is entirely biodegradable and edible and that can be home composted in 4-6 weeks (Figure 19). So far, the packaging has been used to create thin films and coatings for cardboard, takeaway boxes, as well as sachets for condiments.

Wood-based paper packaging:

In 2020, a Scotland-based paper manufacturing company developed a sustainable wood-based alternative to plastic packaging (Figure 20). It is a translucent, functional barrier paper that preserves the quality of food and cosmetics just as well as conventional plastics while ensuring a limited impact on the environment. This pioneering paper is fully recyclable, compostable, bio-degradable, and offers a sustainable alternative to SUP packaging.

Technology status on plastic alternatives with lifecycle assessment development:

The total global production of both bio-based and biodegradable plastics in 2019 was 2.1 million tons per annum. The estimated production growth is a remarkable 14 % over four years and implies that if plastic production stays constant in the next ten years, biodegradable plastics will rise to about 2 % of the total plastic market. The global market for bioplastics and biopolymers is projected to reach US $14.9 Billion by 2024, registering a compounded annual growth rate (CAGR) of 15.6% over the analysis period.

Besides Poly Lactic Acid (PLA), which accounts for 24 % of the global production capacity for biodegradable polymers, mainly starch blends (44 %), other biodegradable polyesters, including PBS and PBAT, Ecoflex (23%) and polyhydroxyalkonates (PHAs) (6 %) are being produced at industrial scale.

An average of 200-kilo tons per annum is produced per type of biodegradable plastic. This value represents approximately 0.0005 % of all plastics produced every year. This small fraction demonstrates the efforts needed to displace the fossil-carbon giant in addition to the enormous market potential of biodegradable plastics.

It is estimated that, as of 2020, more than 61.6% of bioplastics are used in packaging. Due to its bio-based nature, it is predicted that Southeast Asia will see the most considerable increase in terms of production capacity72. This can be attributed to the agrarian economy and the agricultural residues available in Southeast Asia, that will be further utilized to produce biodegradable Bioplastics.

However, the growth of bioplastics also depends on consumer demand and awareness among the people. It is also imperative to make it more affordable so that it can have a broader and better reach. Another important aspect of bioplastics is the time taken to biodegrade and place (in a household or in separate facilities). All this depends on the policies and the standards adopted by countries across the globe, which are altered according to their needs and requirements.

Status of biodegradable resin and monomers manufacturing in India:

Currently, there is no manufacturer of essential synthetic biodegradable plastics (PBAT, PBS, PLA & PHA) in India. Hence, there is an immediate need for commercial manufacturing not only for resin but also for monomers to cater to the demand for biodegradable plastics on a sustainable basis as an alternative to current resin for SUP applications. This is a manufacturing area critical for the uninterrupted and economical supply of raw materials to resin manufacturers and resin supply to product manufacturers.

TECHNOLOGY READINESS LEVEL (TRL) MAPPING OF PRODUCTS–GLOBAL AND INDIA

The current bio-PET production only includes 32 % of bio-derived Monoethylene Glycol (MEG), while the remaining 68 % is fossil-carbon-derived TPA. The disadvantage of biomass as a precursor consists of its highly oxygenated nature biomass that will hinder the synthesis of linear alkyl plastics (e g., bio-PE).

New methods have also evolved to minimize the use of such compounds and move towards greener compounds that are biodegradable and non-toxic. Such compounds in this context are known as Deep Eutectic Solvent (DES), which is a combination of two or more solids that form, through hydrogen bond formation, a eutectic liquid mixture at a temperature lower than the melting point of each compound that is part of the DES. DESs popularly used in this process are Choline Chloride: Urea, Choline Chloride: Oxalic acid, Potassium Carbonate: Glycerol.

In the case of DES, the cellulosic and lignin part is utilized in the production of bioplastic, which is biodegradable. Similarly, in the case of paper plates, dissolved lignin can be obtained from DES, and the subsequent lignin can be used as a replacement for binders in concenters, a soil conditioner, as a filler, or as an active ingredient of phenolic resins, and as an adhesive for linoleum. DES can be reused again for the same purpose.

In recent years, a large number of researchers have been attracted to synthesizing biodegradable polymers that could substitute commercially available polyolefins, which are readily utilized as SUPs, particularly in food-contact articles.

Global themes like sustainable growth and circular economy focus on replacing petro-based products with bio-based renewable products, recycling non-biodegradable products, cleaner and greener processes to produce commodity products, and replacing hazardous chemicals with safer alternatives. One such specific area of concern is to replace conventional plastics with bioplastic, which in turn will reduce pollution and also pay the way for creating wealth out of waste. However, transforming the theoretical possibility into market-ready products that are priced affordably is the biggest hurdle being faced by companies so far.

The key metric used to assess the maturity of these evolving technologies related to each bio-based product is the TRL. It provides us with an idea of how long it took to be commercially viable from its conceptualization stage.

Web Title: Alternative Products and Technologies to Plastics: Is Paper Really Alone?

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)