Reduce Your Process Equipment Grinding Time By upto 50%

Reduce Your Process Equipment Grinding Time By upto 50%

The downtime in any process industry is very critical in term of cost of production. Earlier, Paper industry used to suffer production downtime while coating on boiler. But now new surface engineering significantly has reduced the downtime. Talking to The Pulp and Paper Times Mr. Bhavesh Oza, Managing Director of ATS Techno Pvt. Ltd (see the picture). said “We have three registered technology for boiler tube coating. Boiler has a regular problem of fly-ash erosion because puncture in boiler tube leads to shutdown and heavy losses. We do protective coating on boiler tubes to enhance the life & reduce the downtime significantly. This protective coating has been carried out in Khanna Paper Mills. Earlier, there was occurrence of boiler tube puncture in 6-7 months but after 27 months, there has been no puncture and erosion and it has been performing well.

ATS Techno has been serving in Paper Industry since 1992 providing specialized services related to advance surface engineering. Most of the Paper Machines are playing with water and moisture. That's why paper machine is required to protect itself from corrosion, erosion and wear & tear losses.â€We have already executed more than 500 MG cylinders coating and grinding jobs in India and abroad successfully. We also provide special hard coating for re-winder drum, pope reel and dryer cylinder. ATS performs high chrome steel coating on post size press dryer to counter the erosion & enhance the nonstick properties.†Said Mr. Oza.

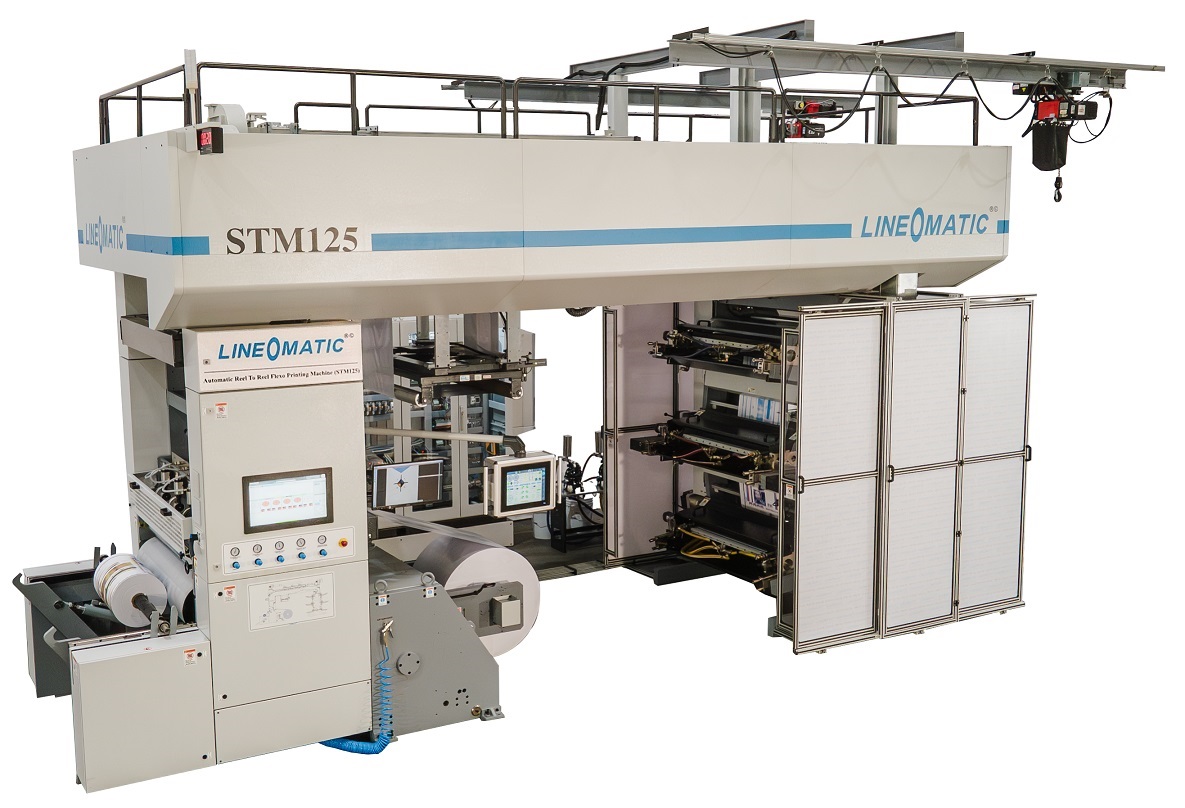

ATS Techno has advance compact dryer grinding machine. The specialty of this machine, it can be fixed between dryers and can grind it without removing the dryer from the machine frame in faster manner saving the valuable downtime. On the question of service competition parameter he said, “We are a surface engineering innovative company, that's why our innovative coating protect us from the heat of the competition. We secure 22 percent market share in pulp and paper industry under secure dryer grinding, boiler tube coating, pope reel & rewinder grinding segments.

ATS is going to launch a new special service for calendar roll precision grinding in next financial year. Mr. Oza said “we are going to install one roll grinding machine of 2 m (diameter) x 10 m face length, an advance rare grinding machine in India itself. Also, we are introducing spray red deposit efficiency; this technology would reduce the coating time to 5 -6 days from 10 days.†Mr. Oza further explained that “we can measure surface run out, paper quality and poorer dimension of the roll through our innovative online service.†Special MG cylinder coating For e.g. 16' dia and 3 meter surface face length. Dual coating technology instead of one machine we mount two coating & two grinding machines on MG by this we reduce half time of the shutdown Other than paper industry ATS is operational in petro chemicals, oil & gas, power, steel, hydro nuclear, having vast spectrum of surface engineering. ATS has office in Bangladesh also.

Web Title: Reduce Your Process Equipment Grinding Time By upto 50percent

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)