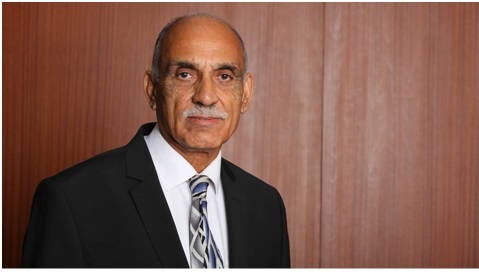

NR Agarwal: new state of the art packaging board mill at Sarigam by March 2024

NR Agarwal: new state of the art packaging board mill at Sarigam by March 2024

-NR Group will market its new product range across the length and breadth of India and overseas

- Board machine is based on the modern multi fourdrinier technology with four forming fabrics and top former

- Raw material for the plant is based on 100% imported pulp and best quality imported and domestic fibre.

The Pulp and Paper Times

NR Group which is well known for its forward looking business approach has now embarked on a challenging project to produce 3,00,000 TPA, the single largest machine in the country of high end packaging boards by investing in a state-of-the-art plant in Sarigam, Gujarat which will come to operation by March 2024.

NR Agarwal Industries proposes to focus its production capacity on value added coated folding box boards (FBB), solid bleached sulphate boards (SBS), cup stock and top end grey back boards. The brand new board machine has a deckle of 3.7 M and will produce boards in the grammage range of 180 to 450.

The board machine is based on the modern multi fourdrinier technology with four forming fabrics and top former (to produce 4 layered boards), and the key equipment are being supplied by the leading global vendors.

The machine is equipped with the latest features like, drum pulper, 4 hydraulic head boxes,dilution control system, auto CD profile control and shoe press for high bulk and stiffness.

The film press is one of the unique feature of the machine which will also enhance bulk and stiffness. The machine will have four online brand new combi coaters, which will ensure excellent printing surface, the coating colour kitchen is one of the most advanced set up.

NR group is also investing in a world class process and quality control system, the auto QCS and DCS control system will ensure precision board quality. The testing laboratory having the latest imported equipment to provide accurate values. This will ensure a consistent quality.

The raw material for the plant is based on 100% imported pulp and best quality imported and domestic fibre. The process technology together with the world’s best raw material will ensure excellence in product quality, both in terms of bulk & stiffness and also very high quality printability, which are the key consumer requirements in the quality conscious consumer packaging industry.

The company has also invested a significant amount on the converting infrastructure with state-of-the-art synchrofly sheeters of European origin and a modern packing line to meet the customer’s needs for perfect reel and sheet quality, ensuring optimum printing & converting benefits for the customer.

The new captive power plant will provide self-sufficiency in power.

Marketing & Customer Support:

NR Group will market its new product range across the length and breadth of India and overseas, especially to the Asian and Middle East countries and will have its footprints in Europe and USA.

The company will be setting up a robust marketing organization manned by a team of experienced professionals, located across country, who will work closely with the customers to provide the best service standards. The mission is to add real value to the customer’s business and ensure both tangible and intangible benefits. The underlying spirit will be to treat the customer as a strategic partner.

Besides the company’s own sales force, the long term customer relationships will be cemented through its team of customer-centric channel partners (company distributors) who will be totally focussed and committed to meeting the individual customers’ day-to-day business requirements.

Web Title: NR Agarwal: New state of art packaging board mill at Sarigam by March 2024

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)