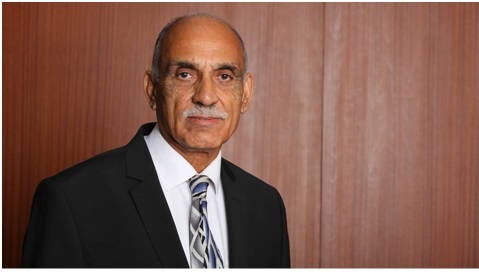

"Paper mills that manage to keep the quality consistent will stay in the market," says Seraphim Papers' MD

Paper mills that manage to keep the quality consistent will stay in the market, says Seraphim Papers' MD

- Overcapacity in one specific segment, need for product variety in range

Sharing about his unit, Mr Parth Kasundra, Managing Director of Seraphim Papers, shared information about his Morbi plant, and shared his understanding of the market.

Sharing about his Morbi unit, he said, “We manufacture specialty papers ranging from 50–100 GSM and between 20 and 240 BF. We supply virgin-based high-quality test liners for paper bag manufacturing, wrapping segments, and direct food contact papers. We manufacture 150 tons per day and are a fullyequipped company.”

The Pulp and Paper Times | Interview:

Q:Today, paper mills are troubled by the situation of overcapacity. How do you see this situation?

The current overcapacity is in one specific segment, e.g., corrugation paper. If you possess a variety of products in your product range, then you don’t need to fear and can depend on small quantities. If you have only one product with a large production capacity, then you need to think about where and to whom you will supply it. If you have a small stock of different products, then it is easier to clear the stock.

Q: What are your views on the current export scenario?

Currently, except China, every country is buying paper. Although not 100%, they are importing papers, and it is a regular supply. But the situation demands the survival of the fittest, and the mills that manage to keep the quality consistent will stay in the market.

Q: When did your project start, and what is the capacity?

The project started around one and a half years ago, and we have developed this product range in the last year or so.

Q: Who is your technology supplier from whom you have taken the technology? And why?

Harjeet Papers have manufactured, supplied, and erected our complete machinery. They were able to meet my specifications and quality needs at the perfect rate.

Q: Are there any plans for the launch of new papers in the future?

Currently, no. But it all depends on the market scenario and what is the demand in the future. Then there are possibilities.

Q: You are supplying to the B2B market. Do you have a product supply for B2C?

We generally supply less to B2B. We supply 20% of our production capacity to B2C directly. We approach customers, they give their vendor list, and we then work with that list for supply to the customers.

Q: What are your plans for the next two years? How is the growth in the Kraft paper industry?

Kraft is not limited to corrugation paper. It has many applications, so it depends on the applications. Corrugation paper has an oversupply, but demand is less. So there are issues; otherwise, if you look at different sectors, then it is fine.

Q: How are you managing the price fluctuation in the prices of the imported fibers?

It all depends on the prices; we are buying and selling it on the same day. We refrain from overstocking or understocking the fibers. You only buy that much, which you require.

Q: It takes time for the arrival of imported fibers. If the price fluctuates during transit, how do you manage it?

It is an open market. We can demand prices from customers if the prices rise. The customers sometimes agree to the increased price. If they don’t, then we need to absorb the impact. It is a part of business.

Web Title: "Paper mills that manage to keep the quality consistent will stay in the market," says Seraphim Papers' MD

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)