Norske Skog Saugbrugs has initiated pre-engineering (main study) to produce bleached chemi-thermomechanical pulp (BCTMP), with expected final investment decision in the first half of 2025

Norske Skog Saugbrugs has initiated pre-engineering (main study) to produce bleached chemi-thermomechanical pulp (BCTMP), with expected final investment decision in the first half of 2025

-In 2023 annual demand for standard newsprint in Europe decreased by 22% as compared to previous year. For magazine paper annual demand decreased by 24%, with supercalendered paper decreasing 23% and lightweight coated paper decreasing 25% compared to previous year

The Pulp and Paper Times

Norske Skog was established in 1962, but our Boyer, Bruck and Saugbrugs mills have been in operation much longer. Until the 1990s, the company grew in Norway, acquiring businesses in pulp, paper and wood-based construction materials.

Norske Skog is a producer of packaging paper and publication paper across five mills in Europe and Australasia. Packaging paper includes testliner and fluting and publication paper includes newsprint and magazine paper. The annual production capacity of packaging paper will be 0.8 million tonnes during 2026 and the annual publication paper production capacity is 1.6 million tonnes. Packaging paper and publication paper are sold through sales offices and agents.

Norske Skog continues to ramp-up production in the packaging paper market following the successful start-up of Norske Skog Bruck PM3. Delivered volumes of recycled containerboard increased during the first quarter. Norske Skog Golbey in France is converting PM1 for production of packaging paper and will start production in the second half of 2024. When full capacity is reached at both Norske Skog Bruck PM3 and Norske Skog Golbey PM1, Norske Skog will have a production capacity of 0.8 million tonnes of recycled containerboard.

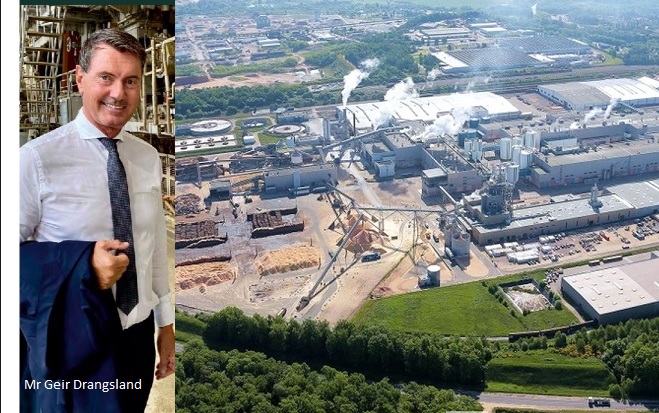

“Even in the face of falling prices for paper and packaging, the entire organization has shown a remarkable ability to adapt to changing market conditions. Swift and innovative adjustments have been the key to navigating through tough times. Through mechanical upgrades and efficient production, we have managed to maintain competitiveness while creating space for new initiatives,” said Mr Geir Drangsland, CEO of Norske Skog in the annual report for FY 2023

Mr Drangsland informed that despite many business challenges in 2023, as the largest shareholder and CEO, I have chosen to implement extensive changes in the corporate management. The goal is to achieve greater breadth of expertise and renewal, which will be crucial going forward. The company is now in a phase where we are implementing major production changes with the conversion of newsprint machines to packaging at Bruck and Golbey, the commissioning of a 50 MW incineration plant at Bruck, and participation in France’s largest bioenergy plant at 125 MW, which will open during the year.

According to FY24Q2 reports of Norske Skog shows that higher operating revenue in the FY24Q2 compared to the previous quarter mainly driven by higher delivery volumes and higher sales price, partly offset by lower income from sale of excess energy. Other operating income increased as a result of insurance recognition at Norske Skog Saugbrugs of NOK 338 million. Publication paper prices were slightly higher in the quarter due to mix effects, and packaging paper prices increased in line with the market. Production of packaging paper increased as ramp-up continued as planned.

“While the conversion at Bruck followed both the schedule and approved budgetary limits, unfortunately, we experienced significant budget overruns at Golbey. Such overruns are unfortunate for our financial reputation and result in lower profitability on the invested capital. We look forward to successfully completing the rest of the project by the opening of the 550 000 tonnes packaging machine in second half of 2024,

Together, these conversions will amount to more than 5 billion Norwegian kroner. Even with these investments behind us, we will create new growth opportunities for the Norwegian factories. The Skogn mill is currently one of Europe’s most productive and cost-effective factories, enabling continued production of newsprint with three machines. Currently, there is a transition in production by increasing pulp capacity and more use of locally sourced timber. This will result in lower emissions of greenhouse gases both in the production process and due to shorter transportation distances for the raw material.

The development in the global economy is of vital importance for consumer spending, and this impacts the publication paper and packaging paper industry, and thus Norske Skog’s operations and results. Norske Skog’s deliveries have continued to improve during the second quarter of 2024 and is expected to improve through 2024.

The raw material and energy markets, which are important for both publication paper and packaging paper production, are expected to remain uncertain, although prices have come down closer to historical levels. Cost of recovered paper has increased significantly, and the quality and availability has deteriorated. This trend is expected to persist for the remainder of 2024. Pulpwood prices is expected to remain at higher levels for 2024.

The level of input costs and demand for paper will continue to influence paper sales prices in Europe. Both publication and packaging markets are characterised by excess capacity and capacity reductions are required to balance the markets. Utilisation is expected to remain weak until capacity is reduced.

The production of recycled containerboard in Norske Skog Bruck is expected to increase in line with plan over the coming quarters. However, the EBITDA from the Packaging Paper segment in 2024 is expected to be negative due to allocation of fixed costs following startup of production in Norske Skog Golbey the second half of 2024.

Norske Skog Saugbrugs has initiated pre-engineering (main study) to produce bleached chemi-thermomechanical pulp (BCTMP), with expected final investment decision in the first half of 2025. Potential investments into a BCTMP project at Saugbrugs will result in recognition and receipt of additional insurance compensation of NOK 615 million.

In Australasia, markets remain challenging with a large share of volume being delivered in low margin export markets. There is continuous effort to improve the mill’s cost position and commercial terms.

Norske Skog will continue to develop its industrial sites with new fibre projects based on efficient use of certified fibre and renewable energy, both on a stand-alone basis and in partnerships.

Norske Skog will face pressure to reduce the environmental footprint in own operations and the value chain and embrace sustainable practices throughout its paper production process. This may entail investments in renewable energy, adoption of recycled materials, and implementation of carbon-neutral initiatives to align with evolving regulatory requirements and societal expectations. Failure to meet these standards could result in reputational damage, regulatory penalties, and decreased market share. Therefore, Norske Skog must maintain flexibility, diversify market exposure, and manage geopolitical risks, and Norske Skog’s financial performance in the future will also be shaped by our ability to adapt to evolving stakeholder expectations, regulatory frameworks, and global market dynamics. The future may present both risks and opportunities for Norske Skog.

WASTE

Norske Skog aims to minimize the amount of waste sent to landfill by implementing waste reduction strategies and maximizing recycling and recovery efforts. By diverting waste from landfills, Norske Skog mitigate environmental pollution and reduce the consumption of natural resources. Only about 2% of the waste from the production processes is deposited in landfills.

WASTE PERFORMANCE

The total quantity of dry production waste, such as sludge and bark, generated by the group in 2023 was 258 641 dry tonnes. In 2023, 70% of the waste was used as biofuel for the bio boilers at the mills generating thermal energy. In Europe 82% of the waste was used for energy purposes, whereas in Australia 93% was used for agricultural purposes.

In addition, 122 566 tonnes of ash, which may be used in concrete or brick making, or in road construction, were generated from the combustion process. Ash residues result from combustion processes involving solid fuels. Agricultural re-use is also an option for some ash and organic materials. However, about 43% of the ash are deposited in landfills. This was higher than prior years mainly due to the new energy plant in Bruck. During 2024, Norske Skog aim to identify new use applications for this ash. Different national legislation put limitation on the use of ash. In Austria, Norske Skog Bruck sells the ash under the product brand name Stabinor for construction purposes. In 2023, 498 tonnes of hazardous waste were disposed through authorised collection systems according to national regulations

The report stated that European publication paper operations experienced a marked change in the operating environment in 2023. The market went from a strong supply demand balance in 2022 to a significantly weaker balance in 2023 following a significant drop in demand for the group’s products. Prices for the products decreased and were driven by a combination of the weak supply demand balance and the underlying decrease in variable costs. Prices for energy, our most important variable cost, decreased closer to levels observed prior to the significant increases in 2022. There was also a decrease in costs for recovered paper and other raw materials, except pulp wood in Norway which increased.

In 2023 annual demand for standard newsprint in Europe decreased by 22% as compared to previous year. For magazine paper annual demand decreased by 24%, with supercalendered paper decreasing 23% and lightweight coated paper decreasing 25% compared to previous year. (Source: Eurograph)

“The Western European recycled containerboard market was in 2023 approximately 21 million tonnes. As the publication paper markets, the packaging market also experienced decreased demand in 2023 although at a lower level, but with the same impact creating a weak supply demand balance. This in combination with lower variable cost, mainly energy and recycled fiber, reduced the market prices of recycled containerboard impacting profitability in the industry,” the report said.

Norske Skog continued with the conversion of Norske Skog Golbey PM1 during 2023. In October Norske Skog announced that the net investment amount for the conversion project at Norske Skog Golbey had increased from EUR 265 to 300 million. The increase was generally due to increased purchase prices for goods and services throughout the project period as well as delayed deliveries of equipment. The start-up of production of packaging in Golbey was postponed to the second half of 2024 due to delivery delays. Once fully ramped up the conversions will add 760 000 tonnes of cost-competitive recycled containerboard capacity.

Web Title: Norske Skog Saugbrugs has initiated pre-engineering (main study) to produce bleached chemi-thermomechanical pulp (BCTMP), with expected final investment decision in the first half of 2025

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)