TNPL unveils ambitious expansion: 100 Tonnes Per Day tissue plant planned for Unit II, Eyes diversification into notebook manufacturing

TNPL unveils ambitious expansion: 100 Tonnes Per Day tissue plant planned for Unit II, Eyes diversification into notebook manufacturing

- We've observed is the rapid decline in pulp prices, which has had a significant positive impact on the paper industry

- The development of low GSM cup stock (140GSM), high-strength mat tissue (HSMT) for applications like earbuds, and base paper for straws as sustainable alternatives to single-use plastics”

- TNPL's recent initiatives have been focused on exploring the potential of paper in various industrial applications beyond their traditional uses

- The lower costs associated with imported pulp and other raw materials are playing a crucial role in reducing our overall expenses, setting a promising tone for the third and fourth quarters of the year.

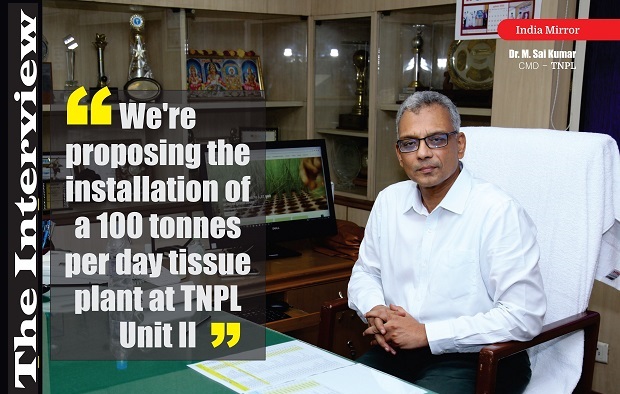

Tamil Nadu Newsprint and Papers Limited (TNPL) places a strong emphasis on environmental performance, waste management, and resource conservation. TNPL actively adopts a circular and sustainable economy model to ensure responsible resource utilization, including water, furnace oil, and key raw materials. In an exclusive interview with The Pulp and Paper Times, Dr. M. Sai Kumar, IAS, CMD- TNPL, shares his thoughts on several topics, including paper demand pulp prices, export and market condition in coming months. He also discusses internal developments and new launches at TNPL. Here is the whole interview he gave.

The Pulp and Paper Times | Sept-Oct 23 Edition:

Q: Please give us a brief introduction of Tamil Nadu Newsprint and Papers Limited (TNPL)

The Government of Tamil Nadu (GoTN) collaborating with the Industrial Development Bank of India (IDBI) founded Tamil Nadu Newsprint and Papers Limited (TNPL) in 1979. IDBI eventually divested its stake, and today, the Tamil Nadu government is the single major shareholder.

Our journey has been one of continuous growth and commitment to industrial progress. Starting with an initial capacity of 90,000 tonnes per annum, we have expanded significantly, currently boasting a capacity of 440,000 tonnesper annum. With its constant growth, TNPL has become the world's largest bagasse-based paper mill, consuming 1.40 million MT bagasse per year and ranking third in installed capacity and second in printing and writing paper production in the country.

Simultaneously, we've scaled up our in-house pulping capacity to an impressive 1580 tonnes per day, with a power generation capacity of 154 MW. To further enhance self-reliance, we've established a wet ground calcium carbonate (WGCC) / precipitated calcium carbonate (PCC) plant with a 300 tonnes per day capacity.

Our commitment to sustainability and zero-waste manufacturing led us to innovate in 2013. We harnessed lime sludge and fly ash, two production wastes, to produce high-grade cement. This pioneering approach made us the sole Indian paper mill with an integrated cement production unit within our campus, boasting a capacity of 900 tonnes per day.

Using this cement, TNPL constructed a production unit spanning 874 acres in Mondipatti, Trichy District, which began paperboard production in 2013. This unit has a capacity of 200,000 MT, contributing to our total production capacity of 640,000 MT annually.

Our growth is fuelled by strategic investments in cutting-edge technology and state-of-the-art equipment. This unwavering commitment to innovation and efficiency empowers us to deliver high-quality production and maintain a competitive edge in the market.

Q: In Comparison to FY22, in FY 23, TNPL revenue increased by a strong 29 per cent to INR 5179 Cr. What are the market factors working behind this whopping jump? Or the better price realization due to input cost reduction.

In FY23, TNPL achieved remarkable revenue growth, increasing by 29% compared to FY22. Several key market factors drove this substantial jump, and I'll highlight some of them.

Firstly, the Writing & Printing segment of the Paper Industry experienced robust demand throughout FY23. This was attributed to the release of pent-up demand following COVID-19 challenges, benefitting the entire paper industry, including TNPL.

Our strategic pricing approach played a pivotal role in our success. We closely monitored market dynamics, allowing us to adapt our pricing strategies effectively, seizing market opportunities and contributing significantly to our sales performance.

Additionally, our production team's focus on increasing capacity was instrumental in encouraging sales. Their commitment to efficiency and productivity drove revenue growth.

Furthermore, our paper sales realization increased by approximately 40% compared to FY22. Part of this was due to the commissioning of a new pulp mill in Unit II during FY23's first quarter, enabling us to produce 100% virgin grade products. We targeted the fast-growing and high-value-added cup stock segment, making a notable contribution to our overall revenue.

In summary, strong market demand, effective pricing strategies, increased production capacity, and a focus on high-value products were key drivers behind TNPL's impressive performance in FY23. We are committed to sustaining this evolution headway and delivering value to our stakeholders.

Q: what is your quick review of the present paper trade market scenario? The pulp prices is rapidly declining. This cost reduction boosts profitability for paper manufacturers and makes their products more competitive in the market. What is your quick analysis of demand and price dynamics of various paper grades, especially WPP and Paper Board segments in the coming months?

Sure, let's take a closer look at the current dynamics in the paper trade market and what we can anticipate in the coming months.

One notable trend we've observed is the rapid decline in pulp prices, which has had a significant positive impact on the paper industry. Lower pulp costs have directly contributed to enhanced profitability for paper manufacturers, allowing us to offer more competitive prices to our customers. This reduction in input costs is indeed a favourable development, as it enables us to provide greater value to our clients.

In the previous quarter, we did witness a somewhat subdued Indian paper market, influenced by several factors, including the global drop in pulp prices and an influx of imported paper products. However, there is reason for optimism as we approach the education and festive seasons, which tend to stimulate demand. Additionally, with the impending peak packaging season, we've been able to reduce our stocks and improve market realizations. The lower costs associated with imported pulp and other raw materials are playing a crucial role in reducing our overall expenses, setting a promising tone for the third and fourth quarters of the year. These factors collectively contribute to a positive outlook for TNPL and the Indian paper industry in the coming months.

Q: TNPL have taken various initial trials on the barriers to paper and paper board and the results are encouraging. TNPL were awaiting the certificates and clearance from CIPET and TNPCB for the compostability and biodegradability so that you can launch the value of coated paper. Please shed some on these developments.

I'd be happy to shed light on the exciting developments regarding our journey towards producing compostable and biodegradable coated paper at TNPL.

At TNPL, sustainability is our core commitment. We've conducted trials to create high-quality compostable and biodegradable coated paper, aligning with our dedication to environmental stewardship. Our R&D teams have made significant progress, showcasing the potential for eco-friendly coated paper.

The approaching launch of our compostable and biodegradable coated paper is a pivotal milestone, offering sustainable alternatives for various applications including packaging, labelling, and promotional materials.. It reflects our unwavering dedication to eco-conscious innovation and reducing the environmental impact of the paper industry.

As for the certification process, we have successfully obtained the necessary certifications from CIPET and have submitted our application to the Central Pollution Control Board (CPCB) for clearance. Once we receive approval from CPCB, TNPCB will grant us the necessary clearance to manufacture and market this product. In the interim, we have finalized our vendors, and the product performance validation has been successfully completed. We anticipate launching these innovative products to the market by November 2023, marking a significant stride towards a more sustainable and environmentally conscious future.

Q: There is a huge demand for writing and printing paper, which is driven by the education sector, and the growth of the eCommerce sector which is creating opportunities. And on the other hand, even today, per-capita paper consumption in India is low. Is the paper sector, which is expecting to yield high returns in the next five to 10 years, carefully calibrating the prices?

Obviously, it's important to recognize that the Indian paper industry has demonstrated consistent growth, averaging an impressive 5-6% annually. This growth rate stands out globally, considering that demand growth in the paper industry worldwide typically hovers around a modest 1-2% per annum.

It's worth noting that while certain segments like newsprint have experienced declines in India, there's a robust upward trajectory in the demand for writing and printing paper, particularly driven by the education sector, with growth at approximately 4-5%. Additionally, packaging papers and boards are leading the way with remarkable growth rates of nearly 8% annually.

In the paper industry, pricing is influenced by a combination of factors, including demand and supply dynamics, as well as input costs. Recently, we've observed lower input costs and increased demand, particularly due to the festive seasons. These developments are expected to have a positive impact on profitability in the upcoming third and fourth quarters of this financial year.

Q: Rating Agency, CRISIL claimed that Indian paper manufacturers could see revenue decline 8-10% this fiscal ( FY 23-24), compared with a steep 30% growth last fiscal, with average realisations expected to soften in keeping with lower raw material prices, and given intense competition. How do you think you could support this assumption?

In the fiscal year 2022-23, paper prices experienced a substantial, driven by factors like high input costs, elevated global commodity prices, supply constraints, and logistical challenges. However, in the current fiscal year, certain input costs have decreased, leading to a correction in paper prices. To fully understand this outlook, we must consider the contributing factors.

One significant driver of the expected revenue decline is the reduction in raw material prices, particularly pulp and fuel. As pulp is a fundamental input for our industry, the downward trend in pulp prices has impacted the average realizations for paper manufacturers, including TNPL.

Intense competition within the Indian paper industry is another influential factor. Competing manufacturers consistently strive to balance quality, pricing, and innovation to maintain market share, exerting downward pressure on prices and affecting revenue.

Market conditions and broader economic factors also play a significant role in revenue trends. Disruptions caused by the pandemic, shifting consumer preferences, and global market dynamics introduce unpredictability into the market.

In response, TNPL has adopted a strategy prioritizing resilience, adaptability, and sustainability. We invest in cutting-edge technology to enhance efficiency, reduce costs, and improve product quality. Our sustainability alignment with the evolving consumer preferences, and diversifying our product portfolio, including paperboard and cement, creates additional revenue streams to offset fluctuations in the paper segment.

While the projected revenue decline in FY23-24 presents challenges, we view it as a natural part of the paper industry's cyclical nature. Our goal remains serving customers with excellence and contributing positively to industry growth.

Q: The big challenge for a paper mill is to protect the margin. Raw material, pulp, coal and chemicals are price sensitive, impacting profitability. How does TNPL protect its margin, especially in the pulp and raw material segment, and what are new initiatives taken by TNPL to increase the raw material availability?

TNPL employs a transparent procurement system that promotes healthy competition among suppliers, effectively controlling raw material costs. We prioritize equitable treatment and prompt vendor payment, enhancing cost control through ongoing vendor development processes.

For bagasse, a crucial raw material, we've established long-term agreements with nearby sugar mills. These arrangements, often involving steam and coal exchange, meet around 60% of our bagasse requirement. The rest is secured through open market purchases and temporary tie-ups with sugar mills.

Regarding pulpwood, essential for both Paper Mill Unit I and Board Plant Unit II, TNPL adopts a diverse sourcing strategy. About 60% of our pulpwood is directly acquired from farmers through TNPL plantation schemes, while 35% comes from government-controlled plantation sources. The remaining 5% is sourced from open market channels.

Direct procurement from farmers, initiated through the Farm Plantation program since 2007–08, has resulted in the direct acquisition of approximately 2.64 million metric tonnes of pulpwood, eliminating intermediaries and benefiting both farmers and the industry.

TNPL has also strategically ordered imported pulp and coal at competitive rates to meet our upcoming needs. We maintain vigilant oversight of the coal and bulk chemicals market, making well-informed procurement decisions to ensure cost-effective solutions that sustain our production efficiency.

In a challenging industry, TNPL thrives while setting an example of flexibility and forward-thinking. Through these initiatives, we remain resolute in our mission to deliver high-quality paper products and cement to meet evolving customer demands, all while preserving profitability and sustainability.

Q: Please shed some light on the latest developments at your company, also future expansion and modifications.

As part of our strategic growth plan, we embarked on Phase I of the Mill Expansion Plan (MEP) in July 2022. This phase involved the installation of a cutting-edge chemical hardwood pulp mill, a chemical recovery island, and enhancements to utilities such as a captive power plant and a wastewater treatment plant. The capital investment for Phase I was approximately 1400 crore, putting us in a good position for the future implementation of Phase II, which will focus on expanding capacity at Unit II.

Another significant project underway is the Revamping of Steam and Power System (RSPS) # 2. This project aims to integrate RSPS # 2 with the existing coal feeding system and steam and power distribution network. It's estimated to be completed by June 2025, with a capital outlay of INR 520 crore, including 100 crore allocated for the current fiscal year.

In line with our commitment to environment and renewable energy, we have plans to harness solar power. Rooftop solar power plants will be installed on buildings at both Unit I and Unit II, contributing to our efforts to reduce our carbon footprint. Additionally, we're set to establish a 2 MW floating solar power plant on water storage reservoirs at Unit I, showcasing our innovative approach to clean energy solutions.

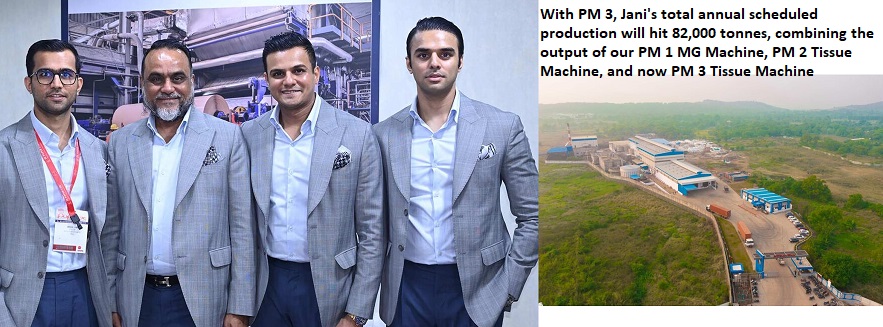

In our pursuit of growth and diversification, we're proposing the installation of a 100 tonnes per day tissue plant at TNPL Unit II. This strategic move marks our entry into the dynamic tissue products segment of the paper industry.

These expansions and initiatives underscore our commitment to maintaining a leading position in the paper and pulp industry. As global markets increasingly adopt environmentally friendly practices and demand high-quality paper and board products, TNPL is poised to make a significant impact. We eagerly anticipate the realization of these projects, as they are set to shape not only TNPL's future but also the entire pulp and paper sector.

Q: The Indian Government is very much aggressive in using hydrogen in industrial processes. Hydrogen could make paper with a 66% reduction in total CO2 emissions. How do you see the energy future of India Paper Industry? What are TNPL’s recent initiatives to reduce energy consumption and optimise the production process?

Let's discuss the future of energy in the Indian paper sector and TNPL's efforts to improve energy and production efficiency.In line with the Indian government's push for cleaner industrial processes, TNPL leads in sustainability and carbon reduction. Our operations are fundamentally energy efficient and sustainable, and CII awarded us the Energy Efficient Unit award in FY 2022-23.

Our achievements in energy conservation are noteworthy:

Our energy-saving projects saved 26 lakh units of power, 3030 metric tonnes of imported coal, and 5089 kilolitres of furnace oil in FY 2022-23. Our efforts saved 40 lakh units of power, 306 metric tonnes of imported coal, and 5073 kilolitres of furnace oil in FY 2021-22.

Additionally, our renewable energy initiatives have yielded positive results:

In FY 2022-23, wind energy generation reached 395 lakh units, growing steadily. Solar energy generation is rising, with 3640 units in the same fiscal year. Our energy mix relies on biomass and biogas, saving furnace oil and imported coal.

We received the title of "Top Performer Designated Consumer for Pulp & Paper Sector of PAT Cycle II" in 2023 for our outstanding performance in the Perform, Achieve, and Trade (PAT) scheme under the National Mission for Enhanced Energy Efficiency (NMEEE).

Rooftop and floating solar panels are among our exciting developments. These initiatives support our environmental stewardship, energy efficiency, and continuous improvement goals. We believe the Indian paper industry can set a global example by adopting hydrogen and other clean energy sources.

Q: Please explain TNPL’s planning to enhance the product portfolio, new launch and operational efficiencies.

TNPL's commitment to enhancing its product portfolio reflects our dedication to delivering high-quality paper products with a reduced environmental footprint that cater to diverse customer needs. In recent years, we have introduced innovative products that have not only garnered industry recognition but have also set new standards for excellence.

Some notable examples include Radiant Print, designed exclusively for sublimation printing in textiles, Radiant Natural Lottery paper tailored for secure lottery printing, and OPAL, an unconventional neutral shade ideal for premium publishing segments. These products exemplify TNPL's commitment to providing environmentally friendly solutions that address the diverse requirements of our customers.

In terms of operational efficiencies, TNPL places a strong emphasis on environmental performance, waste management, and resource conservation. We actively adopt a circular and sustainable economy model to ensure responsible resource utilization, including water, furnace oil, and key raw materials.

As a well-established R&D centre in the Indian paper industry, recognized by the Department of Scientific and Industrial Research (DSIR) Government of India, TNPL serves as a reference point for operational performance indices, particularly in the context of environmental sustainability. Our ongoing focus on enhancing both our product portfolio and operational efficiencies delivering value to our customers.

Q: Considering this typical nature of the market, TNPL has started to increase its focus towards industrial uses of paper such as sublimation papers, Cup Stocks and papers for offline coating applications. Please shed some light on these developments, any new paper in the coming time?

In addition to our existing aqueous-coated heat-sealable barrier papers designed for cup stock and food applications, we offer a diverse range of papers suitable for various industrial uses, including sublimation paper and thermal paper.

We have plans to invest in new machinery to manufacture notebooks using our paper and boards. The evolving trends in both the global and domestic markets indicate a reduced demand for writing and printing papers due to digitalization. Consequently, TNPL's recent initiatives have been focused on exploring the potential of paper in various industrial applications beyond their traditional uses.

Our commitment to diversifying our product portfolio in response to evolving market demands is evident in our ongoing projects. These include the development of low GSM cup stock (140GSM), high-strength mat tissue (HSMT) for applications like earbuds, and base paper for straws as sustainable alternatives to single-use plastics. Currently, we have completed feasibility studies and have progressed to the first-phase manufacturing stage, aligning with our strategic shift towards industrial applications. This reflects our dedication to meeting market needs and ensuring the industrial suitability of our products.

Q: What is TNPL’s assumption for the overall growth of the Indian Paper industry in the next five years?

We expect the Indian paper industry to grow in the next five years for several reasons. Education and economic growth in India boost paper growth above the global average and increase demand for writing, printing, packaging, and specialty papers. Local manufacturing would receive more domestic investments.

Innovation and value-added products, along with digital technologies, boost efficiency and create new market opportunities. Industry growth goals match government initiatives supporting manufacturing, exports, and sustainability.

Global markets want sustainable, high-quality paper, so India's paper industry has great export potential. Sustainable plantation practises guarantee growth-critical raw material supplies. Additionally, the move towards eco-friendly and recyclable products, especially packaging, offers growth opportunities.

Papermakers struggle with fibre. Our industry plants plantation wood for MDF boards and others. These circumstances show that all wood-based industries must prioritise and improve plantation activities to ensure a plentiful and cost-effective fibre supply for all stakeholders.

TNPL is cautiously optimistic about the Indian paper industry's five-year growth. Despite challenges, we believe the industry's commitment to sustainability, innovation, and quality will drive its growth.

TNPL is committed to this growth story by providing high-quality, eco-friendly, and innovative paper solutions that meet customer needs.

Q: Any message you want to convey to the Indian Paper industry?

Absolutely, I'd like to convey an important message to the Indian paper industry. Paper is not just a product; it's an essential element in our lives. When produced and used responsibly, it is exceptionally eco-friendly. It's worth noting that this industry provides livelihoods to around 2 million people in India and plays a crucial role in education and nation-building.

Paper, being recyclable and eco-friendly, contributes significantly to maintaining a clean environment without the burden of toxic waste. It's a resource that deserves recognition for its sustainability.

As paper manufacturers, it is our responsibility to promote and communicate these benefits and advantages to the public. Let's collectively champion the cause of paper, highlight its eco-friendliness, and celebrate its role in our lives and the nation's progress. Together, we can build a brighter future for the Indian paper industry.

Web Title: TNPL unveils ambitious expansion: 100 Tonnes Per Day tissue plant planned for Unit II, Eyes diversification into notebook manufacturing

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)