EU Deforestation Regulation: sustainable production practices and improve supply chain transparency

EU Deforestation Regulation: sustainable production practices and improve supply chain transparency

- Indian Government should also bring out a law similar to the new European Union Deforestation Regulation to combat deforestation

- If an operator is established in a third country but intends to place these products on the EU market, it still needs to comply with these requirements

- Businesses will need to pinpoint the plot of land where the product came from and prove no forests have been cleared on the site since 2020

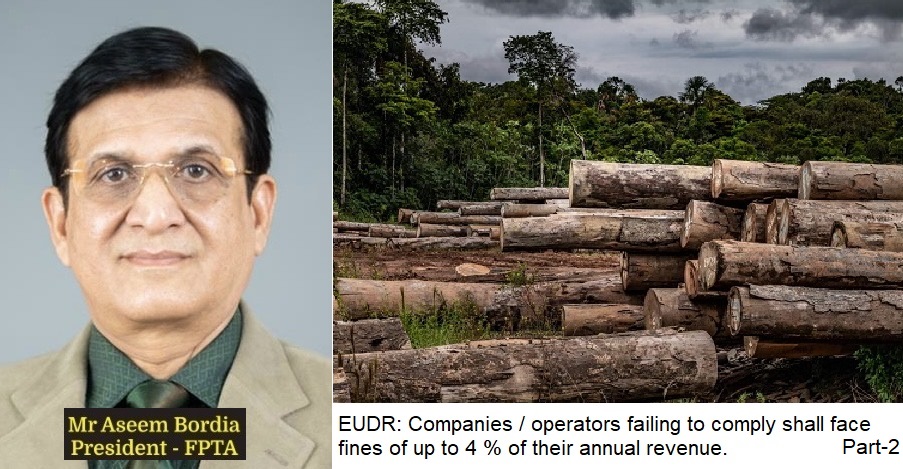

The below article is written by Mr Aseem Bordia, who has become the 61th president of the Federation of Paper Traders Association (FPTA) for the year 2022-2023. The views are personal; Mr. Bordia shares his views on export of paper, Waste paper scenario, Quality of Indian paper products and the present state of the Indian Paper Industry exclusively with The Pulp and Paper Times. Views are personal.

The Pulp and Paper Times:

European Union Deforestation Regulation:

It is also suggested that the government should also bring out a law similar to the new European Union Deforestation Regulation to combat deforestation entered into force on June 29th2023. The Regulation (EU) 2023/1115 makes the operator (manufacturer, or supplier or trader) wishing to making available in the European Union market and the export from the European Union of certain commodities and products associated with deforestation and forest degradation, liable under the regulation, and have to prepare for ensuring compliance, as new due diligence requirements will become applicable as soon as on 30 December 2024.

EU aims at minimizing its contribution to deforestation, forest degradation, greenhouse gas emissions and global biodiversity loss. It identified six relevant commodities (cattle, cocoa, coffee, oil palm, soya, and wood) that – due to their overexploitation – contribute significantly to these problems, and introduced new requirements for placing, making available on the market or exporting these commodities, and other specified products (the so called “relevant products”) that contain, have been fed with, or have been made using these commodities.

Therefore, in order to place or make available on the market, as well as to export these commodities or specified products, three key requirements shall be met. They must be:

1.Deforestation-free: this shall be understood as either the commodity or its components not being subject to deforestation after December 31st 2020, or in the case of wood, it has been harvested from the forest without inducing forest degradation after December 31st 2020 as well.

2.Produced in accordance with the relevant legislation of the country of production in terms of i.e. land use rights, environmental protection, forest-related rules, labor rights, human rights or tax, anti-corruption, trade and customs regulations.

3.Covered by a due diligence statement.

The parties subject to the Regulation are the "operators" (any natural or legal person who, in the course of a commercial activity, places relevant products on the market or exports them), and the "traders" (any person in the supply chain other than the operator who, in the course of a commercial activity, makes relevant products available on the market and Member States). If an operator is established in a third country but intends to place these products on the EU market, it still needs to comply with these requirements.

Businesses will need to pinpoint the plot of land where the product came from and prove no forests have been cleared on the site since 2020. They will need to provide evidence of due diligence, which will likely include satellite imagery.

Companies/ operators failing to comply shall face fines of up to 4 % of their annual revenue.

The Government of India should bring out a law on similar pattern to safeguard and protect environment, green cover and climate. If the manufacturers can comply with such laws for exports, then certainly, they should do so for the domestic markets also.

‘ResourceWise’ in an article dated Aug 9, 23 writes, “The low demand India has been experiencing has been largely due to the global recession and rising inflation. Another major factor at play is the global increase in containerboard supply. Mills in most developed countries have installed recycled paper plants. Two years ago, exports from paper mills within Gujarat and Maharashtra were around 150,000 tons per year. Now, it has decreased to around 30,000 tonnes.” This is the real story behind the extraordinary unilateral price increases the domestic corrugating box makers had to face by the domestic paper manufacturers over the last two years.

While paper manufacturers in other countries are becoming self-reliant, the domestic paper manufacturers seek protection when it faces head winds. Expecting to have the right winds in the sail is asking for too much as the nature has its own way of doing things. Similarly, the global economic and business conditions play out based on several factors over which there is little control. The boat sails and manoeuvres the sea with deft handling.

In the last two years, all integrated writing and printing mills have achieved remarkable success in terms of both sales volume and profitability. Furthermore, the recently unveiled educational policy by the Indian government is expected to foster additional growth in this area. This is primarily driven by the printing of new sets of textbooks and study materials.

In April 2023 the wood pulp crises crashed to a new low globally. Domestic players took advantage of the low prices, but they hardly passed on the benefits to there customers. When the prices of paper were moving north wards, the domestic industry taking full and undue benefit exported more quantity than the imports for the first time in the history of the country and reaped extraordinary gains. The prices were changed unilaterally on a day-to-day basis, pending orders unduly delayed and or not delivered at all. Commitments not fulfilled. Exports were a priority than the domestic markets. The simple explanation was that the industry had no control over the global conditions, demand and supply equation and so forth. If at all higher prices and exports were because of global business conditions and demand and supply equations then lower prices and higher imports are also a reaction to the same conditions. Face it, why crib and cry!

In a news item published on August 18, 2023 in ‘Fastmarkets” it was reported that the European magazine markets were seeing tough times with low demand and rates for light-weight coated (LWC) paper. Given the ongoing challenging market fundamentals, producers of lightweight (LWC) paper and super calendered (SC) paper waged a losing battle with buyers, who continued to push for lower prices over the course of the last quarter.(Annexure 10)

Global supply chain disruptions and shifting trends impact the paper industry. Companies that have diversified their supply chains and invested in contingency planning have been better able to weather the disruptions. Overall, global supply chain disruptions and changing trend dynamics are forcing the paper industry to adapt and innovate. Companies that are able to respond quickly to these changes are likely to succeed in the long term.

Extended Producer Responsibility (EPR):

In order to promote ‘Make in India’ and making the domestic paper sector ‘Atma Nirbhar’ the government should initiate the ‘Extended Producer Responsibility’ (EPR) to the domestic paper industry and make them fully responsible and liable for collection, sorting, and its usage as laid out by the Organization for Cooperation and Economic Development (OECD). India is also a part and parcel of OECD.

OECD defines Extended Producer Responsibility (EPR) as an environmental policy approach in which a producer’s responsibility for a product is extended to the post-consumer stage of a product’s life cycle. An EPR policy is characterised by:

1. the shifting of responsibility (physically and/or economically; fully or partially) upstream toward the producer and away from municipalities; and

2. the provision of incentives to producers to take into account environmental considerations when designing their products.

While other policy instruments tend to target a single point in the chain, EPR seeks to integrate signals related to the environmental characteristics of products and production processes throughout the product chain.

The Packaging Recycling Act: The Application of EPR to Packaging Policies in Japan has been implemented from December 1995. The “Extended Producer Responsibility – Packaging and Packaging Waste in Slovakia” has come in force from July 1, 2001.

The implementation of EPR will lead to better and higher collection thereby meeting the demands of fibre of the industry. Secondly the cost of collection at the local government level would be saved. Above all this would lead to saving of the precious foreign exchange being spent to import pulp and waste paper.

Web Title: EU Deforestation Regulation: sustainable production practices and improve supply chain transparency

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)